The Long and Short of Kurtosis

Michael J. Cleary, Ph.D.

mcleary@qualitydigest.com

Story update 9/17/2018: The formula for kurtosis was missing "n" in the denominator. That has been fixed.

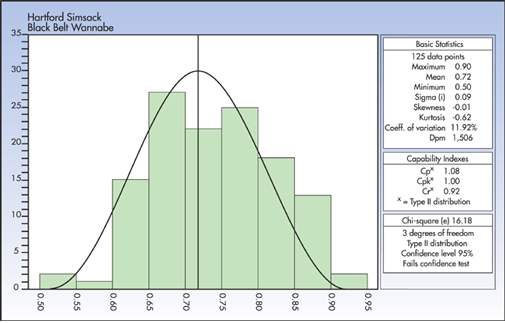

Hartford Simsack’s failed

attempt to harness the power of p-charts in his quest for

the elusive Black Belt hasn’t daunted him. Premature

boasting about his accomplishments—and then falling

short—has renewed his determination to save Greer

Grate & Gate enough money so that he’ll receive

the acknowledgment he so richly deserves for his demonstrated

statistical prowess. In the meantime, his son, who achieved

black belt status at age 11, has given up his martial arts

and gone back to watching cartoons and eating jelly doughnuts.

Line five in Simsack’s plant, which assembles wrought-iron

fencing for interior use, had 421 defects last month, each

of which cost GG&G $150.22. Although Simsack had originally

aimed for savings in the millions, his sights have come

down slightly, and a savings of $63,242.62 that could be

realized from this process piques his interest. Besides,

he thinks he has the answer that will, in fact, generate

these cost savings.

Simsack takes unprecedented action: He discusses the defect

with the line process operator, who has a fairly clear idea

about the defect’s source. Simsack sees an immediate

opportunity to take credit for fixing something. With his

reputation for genius, who would doubt that it was his own

idea?

Armed with a histogram showing that, with a Cpk of 1.0,

the process is barely capable, he mentions to his boss Rock

deBote what a great job he’s done using the power

of statistics to single-handedly improve the company. As

he spreads out the histogram, deBote notices other statistics

relating to the process, including a kurtosis of -0.62.

Noticing his boss staring intently at the kurtosis figure,

Simsack attempts to pass over the number’s meaning

because he has no idea what significance it holds. “Of

course the kurtosis is negative,” he says, shaking

his head in dismay, “but my plan is to improve that

by 100 percent.” Does this make sense in the ongoing

improvement of the process?

No, it doesn’t make sense.

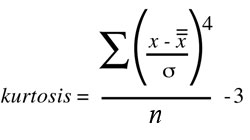

As anyone who hasn’t fallen asleep in statistics class knows, kurtosis is a measure of the combined weight of the tails relative to the rest of the distribution. Sometimes it’s referred to as the

“fourth movement.” The formula for kurtosis

is:

A normal distribution has a kurtosis of zero and is known

as “mesokurtic.”

On the other hand, if a distribution is tighter and taller

than a normal distribution, the kurtosis would be a positive

number. This distribution is referred to as “leptokurtic”

because it has a long tail like a kangaroo.

Finally, for a distribution that is flatter than a normal

curve, the kurtosis would be negative, or “platykurtic”

with a short tail—like a platypus.

If you want to hurl a sophisticated invective at a co-worker,

accuse him or her of platykurtic (i.e., non-normal) tendencies.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a noted authority in the field of quality

management and a professor emeritus of management science

at Wright State University in Dayton, Ohio. A 29-year professorship

in management science has enabled Cleary to conduct extensive

research and garner valuable experience in expanding quality

management methods. He’s published articles on quality

management and statistical process control in a variety

of academic and professional journals. Note: Kangaroo and

platypus drawings are adapted from similar drawings in Donald

L. Harnett’s, Statistical Methods, Third

Edition (Addison-Wesley Publishing Co., 1982).

Letters to the editor regarding this column can be

sent to letters@qualitydigest.com.

|