In Search of the Median Ground

Quality Manager Polly Yurrathain is in deep trouble.

Her boss, Hammond Eggs, has been ranting for days about

the diminishing quality of the company’s products.

Their firm, which manufactures a variety of toy products,

has undergone scrutiny by a major consumer journal; in addition,

stores are complaining about high rates of return for the

toys that Play With Us Inc. manufactures.

Eggs orders Yurrathain to hire “as many inspectors

as needed” to keep defective products from leaving

the assembly line and landing in stores. Yurrathain, who

rarely responds to her boss with anything but a meek, “Yes,

sir,” summons the courage to point out that a system

of prevention is always preferable to one of detection.

“I hired you to prevent mistakes,” her boss

shouts. “And that hasn’t worked, so we’ll

inspect every blasted toy that we make.” He orders

Yurrathain to hire 10 inspectors immediately, at minimum

wage.

Under pressure to get results, Yurrathain goes to the

local employment office and pleads with people in line,

finally attracting 10 who say they’ll show up Monday.

Although only eight workers actually appear on schedule,

Yurrathain is undaunted and decides to teach them about

X-bar and R charts on the first day. The training room is

set with calculators at each station, and she begins to

lecture. These new students do well with the concept of

range:

However, they have a hard time calculating averages despite

Yurrathain’s use of batting averages as a model. They

seem to be totally puzzled by the statistical symbols:

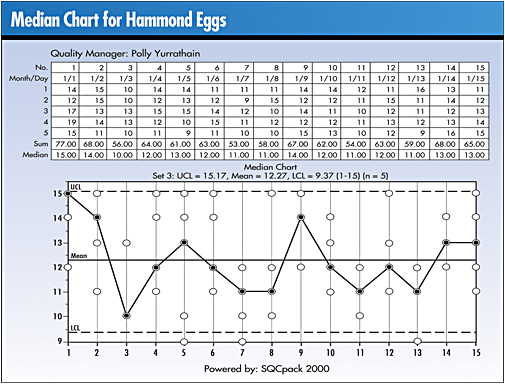

She suddenly recalls the use of median charts, popularized

by Paul Clifford after World War II, where only the median

is recorded rather than the mean. Common practice called

for sample sizes of three or five, so no math was necessary.

For example:

Data: 14, 12, 17, 19, 15

To calculate the median, the data must be ordered from

the smallest to the largest number; the middle number is

the median. In this example, it would be 15.

Excited by this approach, Yurrathain teaches her motley

crew how to do median charts, beginning with the following

formula:

Unfortunately for her, one of the new recruits had been

employed previously as an inspector. Just as Yurrathain

finishes her brilliant lesson, this inspector asks why the

A2 factor is different for median charts than for X-bar

and R charts. He used his calculator to figure that the

A2 factor for median charts, called A2 tilde (~), is about

25 percent larger than the A2 for X-bar and R charts.

Not wanting to embarrass herself by admitting that she

doesn’t know, Yurrathain points out that the square

root of 0.0625 is equal to 0.25. The former inspector accepts

this answer because he isn’t adept at math. Is Yurrathain’s

response appropriate?

The answer is no. Although she didn’t get caught

by the unsuspecting inspector, Yurrathain was wrong. Median

charts offer a good alternative to X-bar and R charts for

two reasons:

They can be done by hand, so for those with limited math

skills, creating the charts isn’t an overwhelming

task.

They can be done by hand, so for those with limited math

skills, creating the charts isn’t an overwhelming

task.

By convention, a median chart shows not only the median

value but also the values of the observations.

By convention, a median chart shows not only the median

value but also the values of the observations.

The real reason that control limits are about 25 percent

wider than for X-bar and R charts deals with the difference

in the way medians and averages are calculated.

The mean uses all the data in a sample to estimate the

central location of the population.

The median orders the samples from smallest to largest

and picks the middle number (assuming an odd sample size)

as an estimate of the central location of the population.

With a sample size of five, all data values are used in

calculating the mean, but only one number is used to determine

the median’s value. It’s as if the calculation

of the median throws away the information in four of the

five pieces of data. One would expect that the mean would

be a more efficient estimator of central location of a population

than would a median. (Note: An “efficient” estimator

is one that is more precise in its ability to estimate a

population parameter.)

Statistician Walter Shewhart was aware of the phenomenon

and noted that the sampling distribution of sample medians

will be about 25 percent more variable than the distribution

of sample means. (Source: Shewhart, W.A. Economic Control

of Quality of Manufactured Product [D. Van Nostrand, 1931])

Poor Yurrathain. She started out well, but because she

was unwilling to take time to investigate, she was wrong.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a noted authority in the field of quality

management and a professor emeritus of management science

at Wright State University in Dayton, Ohio.

A 29-year professorship in management science has

enabled Cleary to conduct extensive research and garner

valuable experience in expanding quality management methods.

He has published articles on quality management and statistical

process control in a variety of academic and professional

journals.

|