Dramatic Statistics, Tragic Flaw

One of Greer Grate & Gate’s

customers, Mandible Manacle Manufacturing, makes handcuffs

and sells them to law enforcement agencies throughout the

United States and Singapore. After an unfortunate spate

of separations and failures in cuffs used to restrain criminals,

MMM has insisted on higher quality throughout its manufacturing

processes and has demanded that Greer Grate & Gate’s

components be produced with a CpK of at least 1.

For Hartford Simsack, this is a piece of cake. In fact,

he sees this as an opportunity to instruct--and hopefully

impress--his assistant, Aiden Abett. He begins by writing

formulas on a whiteboard.

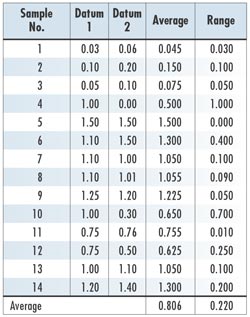

The data comprise 14 samples, with sample sizes of two:

His calculations look like this:

In this case:

To calculate the CpK, Simsack explains that one should

divide the smaller Z value by three:

Simsack has no doubt impressed Abett, although the student’s

eyes have glazed over slightly. “That’s all

there is to it,” Simsack concludes.

A week later, Abett brings Simsack a printout of the same

data, with the X-bar and R charts as well as the histogram

that he’s created from the data. Puzzled, he asks

Simsack to explain the points that seem out of specification.

Simsack dismisses the printout as a computer error because

“Everyone knows that a CpK of 1 or more shows that

you’re making virtually all good parts.”

Is Simsack correct in his observation?

Simsack is, of course, incorrect--again.

Arrogant enough to dismiss any obligation to check his

conclusions, Simsack failed to check the two critical assumptions

that are vital to capability studies:

The X-bar and R chart must indicate that the process is

in control.

The X-bar and R chart must indicate that the process is

in control.

Data must conform to a normal distribution.

Data must conform to a normal distribution.

As the charts below indicate, Simsack’s data violate

not one but both assumptions. Unfortunately, this means

his conclusion--that a CpK of 1.17 represents a great accomplishment--is

tragically flawed, especially when the printout shows 21.4

percent of the data are out of specifications.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a professor emeritus of management science

at Wright State University in Dayton, Ohio.

|