| by Dirk Dusharme

Developing test equipment that

can inspect materials or assemblies without destroying or

disassembling them is of interest to most industries and

critical to many. Aircraft, nuclear facilities and pipeline

inspections would prove cost-prohibitive if it weren’t

for the array of nondestructive evaluation tools available

to those industries.

One key NDE tool is eddy current testing. In commercial

use since the 1950s, eddy current testing provides a versatile

method for the nondestructive evaluation of conductive materials

when access to the material is limited to one side or when

it’s necessary to detect flaws beneath the surface.

Unlike ultrasonic methods, this technology works even when

an air gap exists in the tested material, making it ideal

for nondestructive evaluation of laminated metallic materials.

This article discusses some of the newer eddy current

technologies and their implications for nondestructive evaluation,

particularly when the area under inspection has a large

surface or varying thickness.

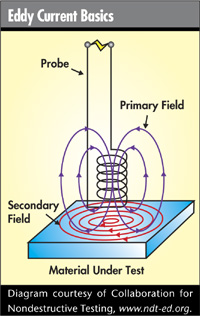

If

you apply an alternating current to a wire wrapped around

a conductor (e.g., the wire in an eddy current probe), an

alternating electromagnetic field forms around the conductor.

Bring this field into proximity with another conductive

material--a pipe, pressure vessel, area of aircraft wing,

etc.--and an alternating electrical current will flow in

that portion of the material as well. This alternating current

causes its own secondary magnetic field that interacts with

(i.e., adds vectorially to) the primary field and results

in a perturbation to the field around the probe, as illustrated

on the right. If

you apply an alternating current to a wire wrapped around

a conductor (e.g., the wire in an eddy current probe), an

alternating electromagnetic field forms around the conductor.

Bring this field into proximity with another conductive

material--a pipe, pressure vessel, area of aircraft wing,

etc.--and an alternating electrical current will flow in

that portion of the material as well. This alternating current

causes its own secondary magnetic field that interacts with

(i.e., adds vectorially to) the primary field and results

in a perturbation to the field around the probe, as illustrated

on the right.

As long as there’s no change in the material or

its proximity to the probe, the perturbation remains constant

and can be measured. If while moving along the material

under test, the probe passes over a crack, a region of corrosion,

an overstressed area, a hole or some other anomaly, a subtle

change in the field occurs. This change can be measured

and compared to measurements on a similar known-good material

and the results quantified by the operator and the eddy

current instrumentation.

Because the response to the magnetic field depends upon

the material’s conductivity, magnetic permeability

and distance from the probe to the material’s conductive

surface, eddy current testers can gather information in

addition to the location of flaws or corrosion. For example,

they can provide information about the physical properties

of the material or the thickness of nonconductive coatings,

such as paint. If the material isn’t too thick, eddy

currents can also measure thickness.

Changing the frequency of the probe’s excitation

current changes the depth to which the probe can penetrate:

the lower the frequency, the deeper the measurement. Thus,

a low-frequency eddy current instrument can detect subsurface

defects or defects on the opposite side of the scanned material.

This makes eddy current testing ideal for detecting corrosion

or cracks in areas invisible from the surface. Often, measurements

are made at multiple frequencies in order to inspect the

material at multiple depths.

However, several issues hamper the conventional technology’s

productivity when the method is used to inspect large areas

of complex parts of varying thickness, such as aircraft

frames. First, distinguishing between defects and probe

liftoff--or mere structural changes such as plate separation,

edges and fasteners--requires multiple-frequency or swept-frequency

eddy current equipment, both of which involve more setup

time than single-frequency measurement. Second, measuring

a sample that has greatly varying thickness requires a different

setup for each thickness in order to obtain optimum defect

distinction and, for each change in structure, a new known-good

specimen must be manufactured for setup purposes. Third,

unlike many measurement technologies, conventional eddy

current inspection takes comparative rather than absolute

measurements and is highly dependent upon users having a

good understanding of the type of material under inspection

and the faults they expect to find. Therefore, it requires

some skill in both setup and interpreting results.

Advances in eddy current technology during the past five

years have addressed some of these problems.

When using conventional eddy current techniques to inspect

materials for flaws that might occur at varying depths,

inspectors must establish multiple excitation frequencies.

In commercial applications, these tests are typically done

in two ways: by taking multiple measurements at different

frequencies using a single-frequency instrument or by using

a multiple-frequency instrument. The former suffers from

obvious productivity issues: Before measuring, the user

must set up the probe and perform a calibration for each

frequency. With a multiple-frequency instrument, the technician

can select from a number of frequencies, which the probe

will use simultaneously in a single measurement. To a certain

extent with either method, users must have some understanding

of the material’s properties, the types of flaws expected

and the depth at which they expect flaws to occur to select

the appropriate frequencies.

A new technology, pulsed (or transient) eddy current,

uses a shaped waveform rather than a continuous sine wave

to excite the coil and generate an eddy current pulse in

the structure. Because a pulse represents the sum of sine

waves for a broad band of frequencies, one test pulse can

contain all the frequencies needed to perform the tests

at different depths, explains Marcus Johnson, associate

scientist with the Center for Nondestructive Evaluation

at Iowa State University. “The real advantage is that

pulsed eddy current is rich in low-frequency components

so you’re able to see near-surface and deeper flaws

at the same time,” he notes.

Iowa State’s pulsed eddy current probe is excited

by a pulse, which generates a broadband eddy current field

in the sample. The higher-frequency eddy current components

are generated more quickly within the material under test

and lead to a rapid, high-amplitude response, as seen by

the probe, says Johnson.

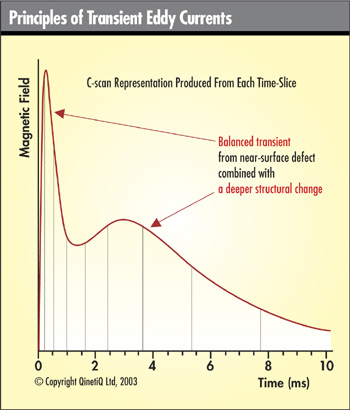

If you look at the pulsed eddy current response as a function

of time, the waveform’s earlier portion corresponds

to near-surface artifacts such as liftoff. The middle portion

corresponds to midsample artifacts such as internal cracks

or interlayer corrosion, and the tail end of the waveform

could indicate overall thickness or show bottom surface

artifacts such as corrosion, as illustrated below.

Pulsed eddy currents offer an advantage over multiple-frequency

probes because users don’t have to select the frequencies

at which to scan, says Robert A. Smith of the United Kingdom-based

QinetiQ Ltd.

“The basic difference is that transient eddy current

captures data covering all the frequencies in the bandwidth,

whereas multiple-frequency eddy current only captures certain

specific frequencies,” says Smith. “This means

that the optimum frequencies for any part of the structure

will always be available from any transient eddy current

scan. For a multiple-frequency scan, the optimum frequencies

would be determined in advance and will be different for

each different structure, requiring several scans over complex

structural changes.”

Pulsed eddy current technology offers more information

about structure and defects than multiple-frequency eddy

currents, adds Jesse Skramstad, president of NDT Solutions

Inc., the U.S. distributor of QinetiQ’s TRECSCAN transient

eddy current instrument. The probe is also much easier to

use, adds Skramstad. “The same probe and simple setup

can be used over a wide range of structural thickness, thus

speeding up the data acquisition process,” he notes.

This technology offers the following advantages, according

to Skramstad:

Because of the broadband characteristic of pulsed eddy current,

the full frequency range is captured in one pass.

Because of the broadband characteristic of pulsed eddy current,

the full frequency range is captured in one pass.

Large areas of structure with multiple variations in thickness

can be scanned without the need for probe or setup changes.

The same setup can be used for different structures, which

are optimized during post-processing. This eliminates the

need for specimens representing the structures encountered,

says Smith. “Unlike traditional eddy current measurements,

pulsed eddy current doesn’t require the production

of multiple known-good specimens for setup or reference

purposes,” he says.

Large areas of structure with multiple variations in thickness

can be scanned without the need for probe or setup changes.

The same setup can be used for different structures, which

are optimized during post-processing. This eliminates the

need for specimens representing the structures encountered,

says Smith. “Unlike traditional eddy current measurements,

pulsed eddy current doesn’t require the production

of multiple known-good specimens for setup or reference

purposes,” he says.

Compared to inductive coils, the use of Hall-effect sensors

(explained later in the article) as field detectors improves

the spatial resolution and detectability of deep defects.

Compared to inductive coils, the use of Hall-effect sensors

(explained later in the article) as field detectors improves

the spatial resolution and detectability of deep defects.

Advanced post-processing analysis tools allow better data

analysis by using algorithms for liftoff compensation, edge

subtraction (i.e., edge correction), total thickness measurement,

plate separation effect elimination, time-slice viewing

and time-domain signal processing. All referencing to known-good

structure can be accomplished on the scan data itself.

Advanced post-processing analysis tools allow better data

analysis by using algorithms for liftoff compensation, edge

subtraction (i.e., edge correction), total thickness measurement,

plate separation effect elimination, time-slice viewing

and time-domain signal processing. All referencing to known-good

structure can be accomplished on the scan data itself.

Johnson cautions that with pulsed eddy current there are

some signal-to-noise issues to consider that don’t

exist with multiple-frequency instruments. In the latter

case, the instrument can lock onto the exact frequencies

being analyzed, eliminating the noise at all other frequencies.

Scanning

eddy current equipment can use an array of individual eddy

current probes in order to increase the area that can be

scanned in one pass. This has huge implications for industries

that require a lot of eddy current measurements, particularly

airframe inspection, in which eddy currents are used to

examine every fastener on an airframe’s surface looking

for minute cracks. Scanning

eddy current equipment can use an array of individual eddy

current probes in order to increase the area that can be

scanned in one pass. This has huge implications for industries

that require a lot of eddy current measurements, particularly

airframe inspection, in which eddy currents are used to

examine every fastener on an airframe’s surface looking

for minute cracks.

“Right now, every single fastener has to be looked

at with a probe using circular symmetry,” explains

Ray Rempt, technical fellow with Boeing Phantom Works in

Seattle. “It takes a minute or more per fastener if

you don’t use an array. You can inspect dozens of

fasteners per minute with a scanning array.” Rempt’s

work with Boeing involves developing scanning arrays of

about an inch wide, enough to span a row of fasteners on

a fuselage. He estimates that eddy current inspection accounts

for about 80 percent of airframe inspection for aircraft

depot operations.

“They cover a larger area in less inspection time,”

agrees Marc Grenier, product manager for R/D Tech, a Quebec-based

developer of ultrasonic and eddy current instrumentation.

“In a single pass, you get a better idea of the structure

of the fault. If you try to do this with a pencil probe,

it’s very difficult to get an idea of the size of

the flaw. With an array, you get a topographic representation

of the defect. So you get shape and depth in a single pass.”

A pencil probe could collect the same information, but it

would take so long to do that the method is usually avoided,

says Grenier. One of R/D Tech's array instruments is shown

above.

The other advantage of eddy current arrays is that they

can be shaped to fit specific geometries--hexagonal, square,

flat and even more complex shapes, such as turbine blades.

“Instead of using robotics with three, four or five

axes to rotate a part around a single probe, you could use

a robot with a single axis to simply move a part in and

out of an array,” says Grenier.

He stresses that eddy current arrays don’t provide

more resolution than would be obtainable with a pencil probe.

In fact, when developing arrays for a client, R/D Tech first

determines which type of standard probe is required for

the measurement task and then creates an array of those

specific probe types.

The number of probes in an array also depends on the task,

he says. “For manual testing in aerospace, lap joint

inspection, looking for corrosion under aluminum or determining

cracks around fasteners, we might typically have 32 elements

in the array,” explains Grenier. “When you go

to tube inspection, our standard X-Probe has 48 elements.”

For more complex applications, the company has supplied

arrays with up to 200 elements.

The key component in any eddy current system is the sensor

used to measure the magnetic field. Traditionally these

have been inductive coils. Although in use for decades,

coils do have a few drawbacks. The coils’ physical

makeup limits them in resolution and measurement depth,

the latter being dependent upon a coil’s insensitivity

to low-frequency signals. The coils’ size also limits

the size of arrays that can be constructed from them.

To address the latter problem, a team from GE Global Research,

GE Aircraft Engines and GE Inspection Technologies has developed

a new product: coils constructed on a thin, flexible plastic

substrate. Instead of wire wound around a core, these flexible

sensors use metal lines (or traces) deposited on a flexible

plastic-like material, similar to a flexible printed circuit

board. They can be designed with single or multiple coils.

“This technology is conformable; we can shape it

to fit any part,” says Mike Bernstein of GE Inspection

Technologies. One application involves measuring dovetail

slots on jet engines, as illustrated on page 26. Using flexible

eddy current sensors in an automated system has allowed

GE to reduce the time for this task, which once took 14

hours, down to about 45 minutes.

A concern that immediately comes to mind is the durability

of these probes in a production environment. “The

arrays have now been in use in our manufacturing operations

for several years,” says Bernstein. “The repeatability

is incredible and the durability is excellent. Although

no probe has an infinite life, the GE array probe is far

more cost-effective than single-element applications. These

don’t last as long [as conventional probes], but we

get a tremendous number of parts inspected per probe.”

The probes are also easily replaced should they wear out,

Bernstein notes, and likens the chore to replacing a razor

blade.

GE has also developed accompanying integrated systems

and software to help deal with typical eddy current measurement

issues, such as automation, liftoff and edge effects.

Another flexible and conformable technology has been developed

by Jentek Sensors Inc. of Waltham, Massachusetts. The company’s

meandering wire magnetometer sensor consists of a primary

winding of a specific shape--typically laid out in the shape

of a square wave pattern with specific distances between

each of the waves. Around this meandering pattern are multiple

secondary windings. As with GE’s flexible coil, the

MWM is constructed as a thin flexible circuit board.

According to articles published by the company, the sensors

have high spatial resolution and reproducibility, allowing

their response to be accurately modeled--cutting down on

the amount of calibration required. Their thinness allows

them to be permanently installed in critical areas for continuous

monitoring of fatigue, according to some sources. We were

unable to contact Jentek to determine if the product has

yet been used in this fashion.

Both wound coils and flexible coils measure magnetic flux

indirectly; that is, they measure the current created in

the coil when its magnetic fields change. This indirect

rate-of-change measurement has limitations when trying to

probe deeper into a material where only low frequencies

can penetrate.

Two new technologies, Hall-effect devices and giant magnetoresistive

sensors, address this issue by directly measuring magnetic

flux. Both offer better spatial resolution at increasing

depth. With a coil you must sacrifice resolution to increase

its sensitivity at lower frequencies.

“The primary advantage of the GMR is that it detects

the field directly,” explains Rempt. “You’re

less dependent on frequency, so you can see deeper better.”

Believing them to be more stable and sensitive than Hall-effect

devices, Boeing is considering GMR to replace anisotropic

magnetoresistive sensors, a similar technology it now uses

for its eddy current probes.

Advances in new Hall-effect devices have somewhat addressed

Boeing’s concern, argues Johnson. Although he agrees

that their sensitivity might be an issue in conventional

eddy current measurements, he maintains that it’s

less of an issue where pulsed eddy current is concerned

because those systems can operate at much higher currents

and produce stronger fields within the sensitivity range

of Hall-effect probes.

Part of the attractiveness of Hall-effect sensors for

Iowa State, QinetiQ and others is that the devices have

been mass produced for decades and lend themselves to eddy

current sensor applications in terms of cost and functionality.

QinetiQ uses Hall-effect sensors in an array constructed

of a single rectangular coil with multiple Hall-effect sensors.

“Hall arrays offer additional benefits of good near-surface

resolution due to the small Hall-effect sensor size coupled

with the deep penetration provided by the large coil, and

hence the large magnetic field,” explains Smith, who

recently presented such an array for use with transient

eddy currents.

Eddy current measurement is a mature technology for the

nondestructive evaluation of conductive materials. It can

inspect for surface, subsurface and rear surface flaws in

thin materials. Recent advances in the technology include

pulsed eddy current, eddy current arrays, flexible probes

and new probe technologies such as Hall-effect and GMR sensors.

All of these advancements in eddy current help improve its

use with materials of varying degrees of thickness, increase

the speed at which measurements can be taken, allow eddy

current probes to reach previously unreachable areas and

improve eddy current’s depth of penetration and spatial

resolution.

Dirk Dusharme is Quality Digest’s technology

editor.

The author would like to thank the following individuals

for their assistance in this article: Marcus Johnson, the

Center for Nondestructive Evaluation at Iowa State University;

Ray Rempt, Boeing Phantom Works in Seattle; Mike Bernstein,

GE Inspection Technologies in Cincinnati; and Marc Grenier,

R/D Tech in Quebec.

For extensive and clearly presented information on

eddy current and other NDE technologies, visit www.ndt-ed.org,

an educational Web site developed by the Collaboration for

Nondestructive Testing and supported by academic and industrial

sponsors.

|