Creating Organizational Excellence--Part One

H. James Harrington

jharrington@qualitydigest.com

For the last 50 years, quality

professionals have tried to impose quality systems on businesses,

governments and academia. And our track record, hasn't been

stellar, especially when you consider that quality control,

total quality control, zero defects and total quality management

have all failed, and Six Sigma is failing.

Why is it that new quality methods inspire an initial

spurt of success before slinking into oblivion like their

predecessors? Their fate is similar to old toys that get

stuffed in a dark corner of the closet when a new toy is

found under the Christmas tree.

This exercise in futility stems from applying quality

initiatives like bandages to an organization when what's

really needed is fundamental organizational change. Treating

symptoms usually doesn't affect a cure.

Organizational excellence is designed to permanently change

a company by focusing on five important elements. Each of

these isn't new by itself, but learning to manage them together

is the key to success in the endless pursuit of quality.

In this column I'll discuss the first key element: process

management.

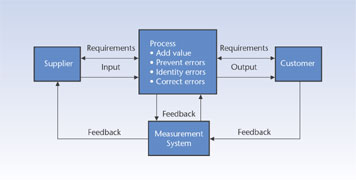

As a concept, process management certainly isn't new to

quality professionals; it's the basis of most improvement

methodologies. A process is a series of interconnected activities

that take input, add value to it and produce output. It's

how organizations do their day-to-day routines. Your organization's

processes define how it operates. Consider the simple process

model below.

In order to manage a process, the following must be defined

and agreed upon:

An output requirement statement between process owners and

customers

An output requirement statement between process owners and

customers

An input requirement statement between process owners and

suppliers

An input requirement statement between process owners and

suppliers

A process that's capable of transforming the suppliers'

input into output that meets the customers' performance

and quality requirements

A process that's capable of transforming the suppliers'

input into output that meets the customers' performance

and quality requirements

Feedback measurement systems between process and customers,

and between process and suppliers

Feedback measurement systems between process and customers,

and between process and suppliers

A measurement system within the process

A measurement system within the process

These five key factors should be addressed when designing

a process. However, the problem facing most organizations

is that many of their support processes were never designed

in the first place. They were created in response to a need

without really understanding what a process is.

The best methodology I know to overcome this problem is

area activity analysis. AAA methodology is a simple approach

used by natural work teams to define the key processes they're

using. AAA defines:

The natural work team's mission

The natural work team's mission

The natural work team's major processes

The natural work team's major processes

The customers for each major process and agreed-upon output

specifications

The customers for each major process and agreed-upon output

specifications

The suppliers for each major process and agreed-upon input

specifications

The suppliers for each major process and agreed-upon input

specifications

The internal process that converts input into output

The internal process that converts input into output

Efficiency measurements for the process

Efficiency measurements for the process

The measurement system

The measurement system

Dividing these elements among the natural work teams reduces

the effort required by any one group and puts the process

understanding in the hands of those who work with it.

So, what's required to manage a process? You must:

Prevent errors. A process must be designed to make it difficult,

if not impossible, to create mistakes.

Prevent errors. A process must be designed to make it difficult,

if not impossible, to create mistakes.

Understand the capabilities of each activity within the

process to produce acceptable output on schedule. This can

be accomplished through process capability studies.

Understand the capabilities of each activity within the

process to produce acceptable output on schedule. This can

be accomplished through process capability studies.

Identify negative changes in the process so they can be

corrected before the process goes out of control. Control

charts do this well.

Identify negative changes in the process so they can be

corrected before the process goes out of control. Control

charts do this well.

Ensure that new people are trained before they become involved

in the process

Ensure that new people are trained before they become involved

in the process

Detect errors resulting from activities that are incapable

of producing acceptable quality levels

Detect errors resulting from activities that are incapable

of producing acceptable quality levels

Report detected errors

Report detected errors

Define the root cause of errors and initiate a process to

eliminate them

Define the root cause of errors and initiate a process to

eliminate them

Obtain customer feedback that defines process errors so

that the process can be improved

Obtain customer feedback that defines process errors so

that the process can be improved

Develop ongoing feedback to your suppliers about their output’s

acceptability and obtain their plan for eliminating unacceptable

input to the process

Develop ongoing feedback to your suppliers about their output’s

acceptability and obtain their plan for eliminating unacceptable

input to the process

As you can see, when it comes to managing it, a process

is almost like a small business. All processes should be

designed, documented, measured and controlled. This is as

true of a chip-manufacturing process as it is of hiring

or accounts payable processes. Most of the work that quality

professionals do is related to continuously improving our

processes. Some of the tools we use include design of experiments,

process capability studies, root cause analysis, document

control, quality circles, suggestions, Six Sigma, Shewhart’s

circles, ISO 9000, just-in-time manufacturing and supplier

qualification, among many others.

Next month I’ll discuss project management, the

key to real improvement. Basically, processes are the way

we do business; projects are the way we improve our processes.

H. James Harrington has more than 45 years of experience

as a quality professional and is the author of 20 books.

Visit his Web site at www.hjharrington.com

. Letters to the editor regarding this column can be sent

to letters@qualitydigest.com.

|