| by Russell T. Westcott

|

The U.S. Technical Advisory Group to ISO Technical

Committee 176 established a Product Support Initiative

task group as a means of obtaining feedback from users

of the ISO 9000 series standards. This initiative

provides guidance for future revisions of ISO 9001

and also factual information to assist organizations

implementing the ISO 9001:2000 and ISO 9004:2000 standards.

The PSI ISO-9004 subteam No. 6 is responsible for

establishing communication channels and products for

feedback and awareness of the ANSI/ISO/ASQ Q9004-2000.

The purpose of the committee is to ensure that standard

users and potential users are aware of the advantages

and uses of ISO 9004 and to solicit input for continual

improvement. This subcommittee consists of Jarvis

Alka, Karen Hitchcock, Sandford Liebesman, Robert

Peach, Art Ramos, Rob Ruel, J.P. Russell, Russ Westcott

and Larry Wilson.

|

As they make their transition

to ISO 9001:2000, many organizations are doing it the hard

way. They purchased the initial ISO documents, concentrated

on deciphering ISO 9001:2000 and relegated the ISO 9004

guideline to obscurity. Meanwhile, they struggle to understand

that value lies in maintaining registration.

The ISO 9004 guideline is a compendium of suggested actions

for improving the potential value of a quality management

system. ISO 9004 answers many of the questions that arise

when an organization implements an initial transition QMS,

and it offers the potential for subsequent improvements.

Solid reasons exist for establishing a value-adding QMS.

The ISO 9001:2000 series allows almost any organization,

regardless of type, size, product, industry or location,

to implement the standard. It allows organizations flexibility

in structuring, documenting, monitoring and continually

improving their QMSs. However, the fact that registering

to ISO 9001 represents the minimum requirements is frequently

unrecognized. The ISO 9000 series doesn’t focus on

maintaining a minimum-level QMS but rather on taking actions

that will continually improve the QMS. And that’s

where ISO 9004 comes into play.

ISO 9004’s strength is its ability to help companies

achieve higher levels of performance. For example, the assessment

tools in the standard’s Appendices A.1 through A.4

can help an organization determine its hot spots for improvement.

Appendix A.3 translates the guidelines into “how”

questions, the answers to which can be most revealing to

those who participate in the assessment process.

ISO 9001:2000 emphasizes management’s involvement.

To convey a continual and consistent message throughout

the organization, management must actively participate in

quality-related decisions and actions. Top management is

usually evaluated on its performance in satisfying the organization’s

stakeholders, especially the owners/investors. An effective

and efficient QMS will directly enhance profitability, cost

containment or budgeting and thus reflect favorably on top

management. This is a key selling point for moving the organization’s

QMS to a value-added system. Also key is assigning the responsibility

for maintaining and improving the QMS to the highest organizational

levels. This is no longer a job for the quality control

department. It requires a recognized and respected positional

authority to manage the QMS over the long term. Implementing

and sustaining a strategic QMS is the business of higher

management.

When an organization adopts a value-added philosophy for

evaluating its QMS’s effectiveness and efficiency,

it should also carefully monitor its resources. This means

setting measurements and monitoring results. Teaching the

entire organization how to apply simple return-on-investment

measures to all improvements will highlight the QMS’s

value-added contribution to performance. All these measured

ROIs enable management, and those who evaluate management,

to understand the importance of the QMS.

A good way to monitor ROIs is to establish a “log

of quality system improvements” as a feature of the

QMS. The LOQSI directs all improvements to a central manager,

who documents the nature of the improvement and its estimated

first-year, or partial year, ROI. A summary of these ROIs

is presented at each management review. Appropriate recognition

is directed to those who contributed to the ROIs, and all

improvements are scanned for lessons that might be implemented

elsewhere within the organization.

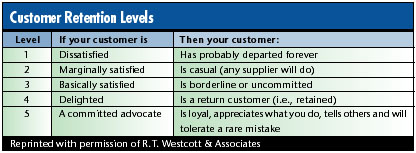

ISO 9004 emphasizes customer satisfaction. It focuses

on how the quality policy embraces customer needs and expectations

and how an organization can interpret their relevance. The

guideline also addresses the resources and processes that

will satisfy customer needs and expectations, and outlines

how to collect and analyze the data. Thus, the guideline

addresses factors that lead to customer retention and refer

your organization to potential customers. Consider the five

scenarios:

The outcome of a strategic planning process is to deploy

goals and objectives throughout the organization. Operational

(i.e., tactical) objectives and plans support actions to

achieve strategic goals. An organization closely monitors

action plans, makes informed course corrections, and measures

and analyzes the results. Inherent in a well-planned strategic

process is attention not only to the customers but also

to the marketplace.

Marketplace competition is intensifying. Use ISO 9004

for guidance in maintaining and improving your position.

Begin by assessing your organization. An effective and efficient

QMS can help:

Decrease variation in its processes

Decrease variation in its processes

Continually improve, organize and deliver customer needs

and expectations

Continually improve, organize and deliver customer needs

and expectations

Do it faster and at less cost than its competitors

Do it faster and at less cost than its competitors

ISO 9004’s Appendix A.5 lists 27 benefits that might

apply to your organization. If your company is going to

stay in the game, it must continually strive to improve

the potential of ISO 9001. The smartest way to do this is

by using ISO 9004.

Should an organization first implement an ISO 9001-based

QMS or undergo the process of applying for a quality award?

Each approach has its own purpose. There are some similarities,

but look at some of the differences:

An ISO 9000-based QMS focuses entirely on establishing an

effective and efficient QMS. Quality award criteria such

as the Baldrige National Quality Program focus on the whole

organization and the environment in which it functions,

the effectiveness of its approaches (e.g., breadth and depth),

and--for a relative few--qualifying for an award.

An ISO 9000-based QMS focuses entirely on establishing an

effective and efficient QMS. Quality award criteria such

as the Baldrige National Quality Program focus on the whole

organization and the environment in which it functions,

the effectiveness of its approaches (e.g., breadth and depth),

and--for a relative few--qualifying for an award.

ISO 9001:9004 concerns itself with organizational reliability

and compliance (i.e., avoiding failure), whereas the Baldrige

criteria focus on organizational excellence and strategy.

ISO 9001:9004 concerns itself with organizational reliability

and compliance (i.e., avoiding failure), whereas the Baldrige

criteria focus on organizational excellence and strategy.

ISO 9001:9004 is more detailed and prescriptive than the

Baldrige criteria.

ISO 9001:9004 is more detailed and prescriptive than the

Baldrige criteria.

ISO 9001:9004 addresses eight management principles that

are also in the Baldrige criteria; however, the Baldrige

criteria add additional core values including:

ISO 9001:9004 addresses eight management principles that

are also in the Baldrige criteria; however, the Baldrige

criteria add additional core values including:

- Visionary leadership

- Organizational and personal learning

- Agility

- Managing for innovation

- Creating value

The assessment process for ISO 9001 certification and subsequent

surveillance focuses on compliance with the standard, conforming

to practices documented in the QMS and finding deficiencies

that need correcting. The registrars that conduct assessments

are paid by the client. The Baldrige examination process

is more extensive and is conducted entirely by trained,

nonpaid volunteers.

The assessment process for ISO 9001 certification and subsequent

surveillance focuses on compliance with the standard, conforming

to practices documented in the QMS and finding deficiencies

that need correcting. The registrars that conduct assessments

are paid by the client. The Baldrige examination process

is more extensive and is conducted entirely by trained,

nonpaid volunteers.

The ISO 9001-registered QMS remains in effect as long as

surveillance audits indicate the system is in compliance

and working effectively--and the registrar is paid. A Baldrige

Award is basically a one-time event. Unlike the certified

QMS, the Baldrige Award has no built-in leverage to keep

the process functioning effectively.

The ISO 9001-registered QMS remains in effect as long as

surveillance audits indicate the system is in compliance

and working effectively--and the registrar is paid. A Baldrige

Award is basically a one-time event. Unlike the certified

QMS, the Baldrige Award has no built-in leverage to keep

the process functioning effectively.

Neither ISO 9000 nor the Baldrige criteria ensure that the

product or service is of acceptable quality or meets customer

requirements. It’s implied that if the certified QMS

or the Baldrige winner has followed its processes and approaches,

the product or service should be good.

Neither ISO 9000 nor the Baldrige criteria ensure that the

product or service is of acceptable quality or meets customer

requirements. It’s implied that if the certified QMS

or the Baldrige winner has followed its processes and approaches,

the product or service should be good.

There’s also no guarantee that ISO 9001 registration

or the Baldrige Award will ensure that an organization will

live long and prosper. Neither process addresses everything

needed for an organization to remain viable, although the

Baldrige criteria do offer more guidance in overall management.

There’s also no guarantee that ISO 9001 registration

or the Baldrige Award will ensure that an organization will

live long and prosper. Neither process addresses everything

needed for an organization to remain viable, although the

Baldrige criteria do offer more guidance in overall management.

Which should an organization attempt first? Absent any

hard and fast rule, implementing an ISO 9001-based QMS and

getting certified would appear a logical first choice for

the following reasons:

Depending on what quality measures are already in place,

a QMS could be implemented within a range of six to 18 months.

Typically, Baldrige winners take three to five years or

more to reach a winner’s qualification--and then there’s

the limitation on how many awards may be given each year.

Depending on what quality measures are already in place,

a QMS could be implemented within a range of six to 18 months.

Typically, Baldrige winners take three to five years or

more to reach a winner’s qualification--and then there’s

the limitation on how many awards may be given each year.

An organization must develop and follow its QMS according

to ISO 9001’s documentation. It also instills the

quality policy, principles and continual improvement practices

among employees. It institutes organization and standardization.

It firmly inculcates management in the need for data-based

decision making and measurable results. And it helps employees

to be aware of customers’ needs and the organization’s

desired outcomes.

An organization must develop and follow its QMS according

to ISO 9001’s documentation. It also instills the

quality policy, principles and continual improvement practices

among employees. It institutes organization and standardization.

It firmly inculcates management in the need for data-based

decision making and measurable results. And it helps employees

to be aware of customers’ needs and the organization’s

desired outcomes.

ISO 9001-based and ISO 9004-enhanced QMSs create a solid

foundation upon which building toward the Baldrige criteria

is less threatening and potentially less costly.

ISO 9001-based and ISO 9004-enhanced QMSs create a solid

foundation upon which building toward the Baldrige criteria

is less threatening and potentially less costly.

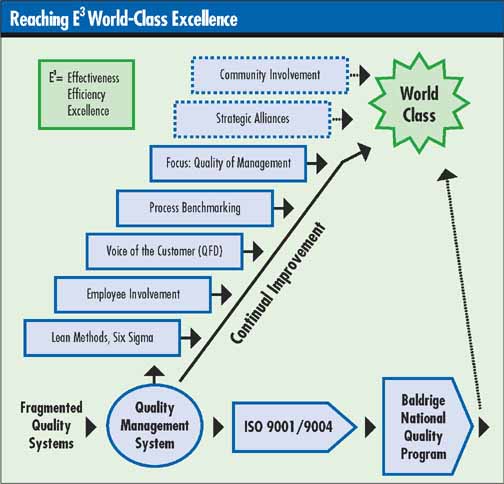

A value-adding QMS is a necessity for survival for all

types of organizations. The most efficient way of establishing

one is by using the guidelines outlined in ISO 9004. Companies

should build an ISO 9001-based QMS and then expand to broader

Baldrige-type criteria to achieve E3 status (as illustrated

above):

ISO 9001 for effectiveness

ISO 9001 for effectiveness

ISO 9001:9004 for efficiency

ISO 9001:9004 for efficiency

ISO 9001:9004 plus applicable Baldrige criteria for excellence

ISO 9001:9004 plus applicable Baldrige criteria for excellence

Russell T. Westcott is president of R.T. Westcott

& Associates, a consulting firm that assists clients

with strategic planning, QMS implementation and registration

process applying management concepts such as lean manufacturing

and benchmarking as well as applying for Baldrige-type awards.

He’s a fellow of the American Society for Quality,

an ASQ Certified Quality Auditor and Certified Quality Manager,

and serves on several committees of ASQ’s Quality

Management Division. He’s the author of Stepping

Up To ISO 9004:2000 (Paton Press, 2003). Letters to

editor regarding this article can be sent to letters@qualitydigest.com.

|