| by Sidney Vianna

Few people pay attention to

the forewords of international standards. If they did, they

might be surprised by what they learn. For example, the

foreword of AS9100 Revision B states, “The establishment

of common requirements, for use at all levels of the supply

chain, by organizations around the world, should result

in improved quality and safety and decreased costs, due

to the elimination or reduction of organization-unique requirements

and the resultant variation inherent in these multiple expectations.”

Who would have thought that an international quality standard

would promote cost reduction? For many, this seems an oxymoron.

Yet, for organizations that have implemented AS9100 and

related standards, the statement represents the simple truth.

Quality improvement and cost reduction in the aerospace

industry is a unique concept. It started with the vision

of a few quality leaders who recognized the benefits of

developing internationally accepted quality management system

standards.

Fortunately for us, they realized the potentially huge

benefit of harmonizing system requirements for aerospace

suppliers.

For example, AS9100 reduces costs and improves quality

by eliminating multiple variations of the same requirements.

For decades, aerospace suppliers were inundated with customer-specific

requirements that often demanded slightly different ways

of accomplishing the same task. Because AS9100 harmonized

these requirements worldwide, suppliers can now focus on

developing a single quality management system acceptable

to all their customers--and thereby reduce waste and redundant

effort.

Another potential cost-saving benefit bestowed by AS9100

is the industry’s increased reliance on accredited

certificates issued by specifically approved registrars.

Redundant and inconsistent customer audits have always been

a source of complaints for aerospace suppliers. Some undergo

more than 50 customer audits a year--basically one audit

per week. Suppliers have employees who do nothing but coordinate

and facilitate customer audits. Any company that’s

experienced such a heavy auditing schedule knows that repeated

QMS audits disrupt day-to-day activity and hamper efficiency.

Imagine, for example, your supplier quality assurance engineers

spending four hours per week answering auditors’ questions

about supplier performance monitoring. This alone represents

10 percent of a weekly workload.

However, if customers can rely on certificates issued

by independent, accredited and competent registration bodies

attesting to the supplier’s AS9100-compliant system,

they can focus their time and resources on product- and

process-specific assessments instead.

These improvements to the cumbersome supplier-OEM relationship

presented a cost in terms of a change in thinking. In order

for aerospace OEMs, primes and regulatory authorities to

have confidence in the certificates and accept them as a

component of the supplier oversight process, the industry

had to enhance existing mechanisms of registrar and auditor

competence and performance monitoring. Instead of relying

on a typical third-party process, an Industry Controlled

Other Party process was developed.

Under the ICOP process, registrars still apply for accreditation

through organizations such as ANSI-RAB NAP, INMETRO, SCC,

COFRAC, UKAS and others. However, the accreditation bodies

themselves are subject to approval and monitoring by aerospace

representatives. Further, the registrars are subject to

joint (i.e., accreditation body/OEM) oversight; office visits

and audit witnessing are two common mechanisms used to verify

the registration process’s integrity.

Due to the particular requirements for auditor competence

and registrar qualifications, a sector-specific document--SAE

AIR 5359, presently in Revision B--was created to outline

the additional requirements. Registrars and auditors are

measured against the requirements contained therein before

being granted approval to issue AS9100 certificates. Subscribers

at all levels of this process also agree to provide right-of-access

to regulatory agencies such as the FAA and JAA for their

oversight.

Presently, nine accreditation bodies are approved for

AS9100:

ANSI-RAB NAP (United States)

ANSI-RAB NAP (United States)

INMETRO (Brazil)

INMETRO (Brazil)

SCC (Canada)

SCC (Canada)

UKAS (United Kingdom)

UKAS (United Kingdom)

COFRAC (France)

COFRAC (France)

ENAC (Spain)

ENAC (Spain)

SINCERT (Italy)

SINCERT (Italy)

TGA (Germany)

TGA (Germany)

JAB (Japan)

JAB (Japan)

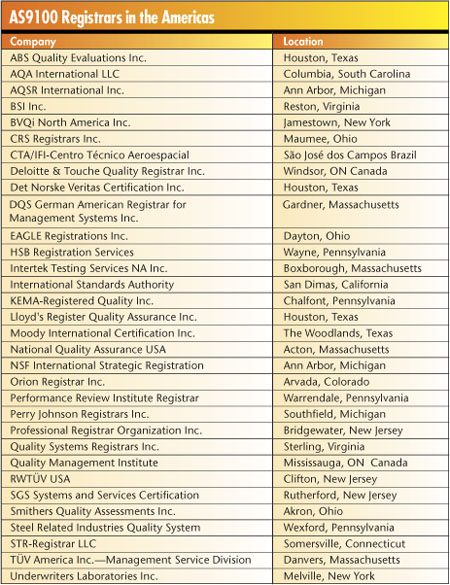

In the Americas, 32 registrars are approved for AS9100.

They are listed in the table below.

As proof that these oversight efforts aren’t simply

an exercise in rubber-stamping, some registrars have had

their AS9100 accreditation temporarily suspended. The aerospace

industry is serious about ensuring that integrity is maintained

in the registration process, which in turn should provide

much-needed confidence to all stakeholders, especially in

regulated sectors.

In addition to the process described above, some OEMs

are going further.

The Boeing Co., for example, performs certificate validation

audits during which Boeing auditors visit AS9100-registered

suppliers to ensure that their systems deserve registration.

Much effort has been made to ensure that AS9100 requirements

are accepted and adopted not only by U.S. aerospace OEMs

and primes but also by their counterparts in Europe, South

America and Asia.

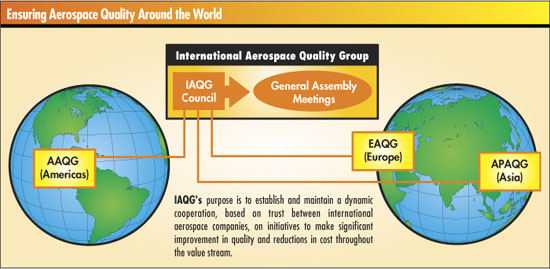

In order to accomplish this, three aerospace sectors were

created around the world to allow the industry to speak

with a single voice to its global supplier base: the Americas

Aerospace Quality Group, the European Aerospace Quality

Group and the Asia Pacific Aerospace Quality Group. Together,

these sector schemes compose the International Aerospace

Quality Group. Each group determines the standards bodies

responsible for controlling their respective documents.

In the Americas, SAE performs this task; in Europe, it’s

the AECMA; and in Asia Pacific, SJAC maintains the documents.

For more information about the IAQG and AAQG, visit the

organizations’ respective Web sites at www.iaqg.org

and www.sae.org/aaqg.

During the process of developing AS9100, quality professionals

realized that the sectors would benefit from a number of

additional documents. Many of these have been harmonized,

meaning all three sectors have agreed to make their standards

identical. A few documents pertain to a single sector; to

differentiate these, documents designated as “91xx”

represent those that are harmonized, whereas standards designated

as “90xx” aren’t adopted universally.

For example, SAE AS9100 contains exactly the same requirements

as AECMA EN9100 and SJAC 9100. On the other hand, AS9003

doesn’t have an equivalent document in Europe or Asia

Pacific.

Noteworthy documents in the AS family of standards include:

AS9101--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9100 standard

AS9101--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9100 standard

AS9003--A system for noncomplex aerospace suppliers that

focuses on inspection and test systems

AS9003--A system for noncomplex aerospace suppliers that

focuses on inspection and test systems

AS9102--An industry-harmonized document about performing

and reporting on first-article inspections

AS9102--An industry-harmonized document about performing

and reporting on first-article inspections

AS9103--Assists organizations interested in variation management

of key characteristics

AS9103--Assists organizations interested in variation management

of key characteristics

AS9110--Details the quality system requirements for organizations

involved in repairing and overhauling aerospace parts

AS9110--Details the quality system requirements for organizations

involved in repairing and overhauling aerospace parts

AS9111--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9110 standard

AS9111--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9110 standard

AS9120--Quality Management Systems--Lists aerospace requirements

for stocklist distributors

AS9120--Quality Management Systems--Lists aerospace requirements

for stocklist distributors

AS9121--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9120 standard

AS9121--An assessment checklist and reporting template to

capture the results of the assessments performed to the

AS9120 standard

Other documents have either just been released or remain

in the deliberation process. These include AS9006 and AS9108,

which deal with deliverable software and statistical product

acceptance requirements, respectively.

AS9100 continues to inspire cost-reducing quality improvements,

not only to organizations registered to the standard but

also to aerospace regulations in general. To keep abreast

of developments, industry players can access the Online

Aerospace Supplier Information System, the official database

of up-to-date information. Among other information, it lists

approved accreditation bodies, registration bodies, aerospace-experienced

auditors and, finally, the registered suppliers that have

already attained accredited registration. As of early May,

more than 1,000 suppliers were listed in the OASIS database,

as seen online at www.iaqg.org/oasis.

Sidney Vianna is the western district manager for

DNV Certification, one of the world’s leading registrars.

He’s responsible for business development and customer

interface as well as supervising a team of 19 lead assessors

in the Western United States. Vianna is an IRCA QMS 2000-certified

lead assessor and has been involved with management system

registration since 1988. Vianna represents DNV in AAQG meetings.

A longstanding member of ASQ, he’s been a past programs

chair for the Orange Empire Section. He recently reinstated

the Los Angeles ISO Users Group.

|