Poisoned by Assumption

Karmond Geeya is a quality

technician for Coastal Cruisers Co., an organization that

produces outboard motors for marine vessels. He’s

responsible for final assembly of these motors, including

paint and trim, and for inspecting each product prior to

shipping. The inspection includes a variety of characteristics

representing quality components that CCC is interested in

producing. One inspection process addresses paint applications,

where defects are detected and recorded as data for analysis.

Geeya, who always reads the latest news in his field,

has discovered the helpfulness of c charts in statistical

process control and finds a pleasing synchronicity in using

this particular kind of chart for paint inspection. “After

all,” he notes wryly to his assistant, Hyde N. Sikh,

“it seems only fitting that CCC should use c charts.”

According to the textbook that Geeya has been consulting,

c charts should be used for discrete events. “Well,”

he muses, “a pit in the paint job is certainly a discrete

event.” Other requirements stipulate that the event

should be defined by one limited area (one motor, for example);

defects should be independent of each other; each type of

defect should occur infrequently; and the number of defects

in each sample should be independent. These factors are

characteristics of the Poisson distribution--something that

Geeya unfortunately calls the “poison” distribution.

As he instructs Sikh about the use of these charts, Geeya

reviews each of the assumptions, and the two of them decide

that, indeed, the analysis would be addressing discrete

occurrences, the defects would be confined to a well-defined

area--in this case, one motor--and that they’re independent

of each other. Sikh notes that the number of defects seems

to run up and then down. Geeya tells Sikh not to worry.

“I am a competent expert in SPC,” Geeya states

confidently.

Is

Geeya correct in his view that the number of defects going

up and down doesn’t matter? Is

Geeya correct in his view that the number of defects going

up and down doesn’t matter?

By disregarding one of the essential assumptions, Karmond

Geeya is rendering the use of his c chart invalid. All of

the assumptions must be met. These assumptions are:

The occurrences of a defect type are discrete.

The occurrences of a defect type are discrete.

The area of opportunity (e.g., a motor) is well-defined.

The area of opportunity (e.g., a motor) is well-defined.

The occurrence of one type of defect isn’t influenced

by the occurrence of another type.

The occurrence of one type of defect isn’t influenced

by the occurrence of another type.

The probability of any one type of defect’s occurrence

is small.

The probability of any one type of defect’s occurrence

is small.

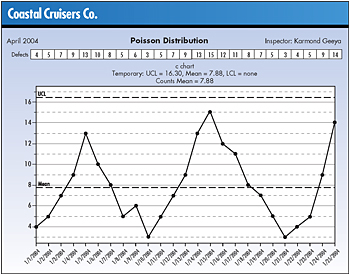

In looking at the graph of the data, it appears that the

samples are not independent of each other. As can be seen,

there’s clearly a pattern of going up and then down

over and over again. It’s interesting to note that

even though this pattern is obvious, no points are outside

the control limits and there are no runs.

It appears that Geeya has truly created a “poisonous”

control chart.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a noted authority in the field of quality

management and a professor emeritus of management science

at Wright State University in Dayton, Ohio. A 29-year professorship

in management science has enabled Cleary to conduct extensive

research and garner valuable experience in expanding quality

management methods. He has published articles on quality

management and statistical process control in a variety

of academic and professional journals.

|