Please Don't Feed Averages

Michael J. Cleary, Ph.D.

mcleary@qualitydigest.com

The behavior of averages can

be as fascinating as that of animals. Hartford Simsack,

intrepid quality manager for Greer Grate & Gate, sometimes

thinks of himself as a visitor to the zoo, watching his

averages and trying to anticipate what, to him, was always

a complete surprise in the behavior of data. "I never

know if this is going to turn out to be a normal distribution

or not," he told his mentor, Dr. Stan Deviation.

Deviation cleared his throat and reminded Simsack yet

again that one of the keys to predicting the shape of the

averages lies in sample size. Regardless of the distribution

shape of the parent population, the distribution of sample

means from that population will follow a normal distribution

if the sample size is, for example, five. You'll remember

that in July's column, Deviation demonstrated a simulation

model with 1,000 samples of the sizes one and two from two

populations to demonstrate the shape of the distributions

from both. Unfortunately, Simsack doesn't recall either

the column or his mentor's lecture about this point.

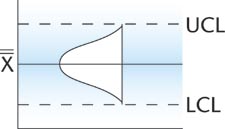

The charts below demonstrate the concept:

Simsack can never quite get his mind around this concept.

Unfortunately for him, however, his boss can and often asks

him for an explanation. Rock DeBote not only wants an answer,

but he also wants to understand the concept well enough

so that he can derive his own understanding. After his conversation

with Deviation, Simsack is quick to respond to nearly every

question about distribution, "It all depends on sample

size." DeBote isn't content with this superficial answer

and presses Simsack for the statistical concept responsible

for this outcome.

"It's the central limit theorem," Simsack responds

smugly.

This is a term with which he's familiar, and it's what

comes immediately to his lips. Is he correct?

Amazingly, Simsack drops the right term this time. The

behavior of averages in this case is indeed related to the

central limit theorem. In June's column, we examined the

rules for determining out-of-control situations, noting

that the important caveat is not which set of rules to use

but rather to use them consistently.

Some disagree about whether the central limit theorem

is needed as a basis for these sets of rules. Some note

that Walter Shewhart never cited the central limit theorem

in his seminal work, Economic Control of Quality of Manufactured

Products (D. Van Nostrand Co. Inc., 1931). In my university

experience, students have proved able to understand the

central limit theorem once they grasp the difference between

averages (X) and individual values (Xi) and the ways in

which the two behave.

The easiest way to demonstrate the central limit theorem

is by using PQ Systems' Quality Gamebox. As noted above,

if one takes 1,000 samples from a known population, then

creates a distribution of sample means (n = 2), that distribution

will be different from the population. Using Quality Gamebox,

but taking a sample size of five, the following results

ensue:

The most interesting result lies in the appearance of

the distribution of sample means from the bimodal parent

population. This clearly demonstrates the application of

the central limit theorem:

The mean of the sample means' distribution is close to the

population's mean.

The mean of the sample means' distribution is close to the

population's mean.

The shape of the distribution of sample means is normal-looking.

The shape of the distribution of sample means is normal-looking.

The sample means' distribution variability is less than

the parent population.

The sample means' distribution variability is less than

the parent population.

Note: It's equal to the standard deviation of the population

divided by the square root of the size of the sample used

to create the distribution of sample means:

Once one understands the central limit theorem, the three

basic rules for an out-of-control situation are easily derived.

The most commonly accepted out-of-control rules were derived

directly from the central limit theorem:

Any point outside the control limits is out of control.

The probability that this will happen when a system is in

control is 0.0023. A point appearing outside the control

limits is a signal that the process is out of control.

Any point outside the control limits is out of control.

The probability that this will happen when a system is in

control is 0.0023. A point appearing outside the control

limits is a signal that the process is out of control.

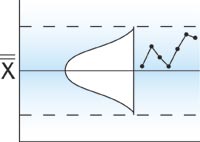

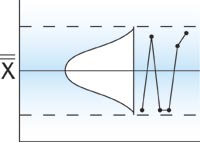

Runs above the mean or below the mean equal 0.0073 and indicate

an out-of-control signal. If seven averages in a row become

larger or slower, this is called "runs up" or

"runs down." Such an occurrence is unlikely for

a process that is in control, so this would be considered

a signal for an out-of-control situation.

Runs above the mean or below the mean equal 0.0073 and indicate

an out-of-control signal. If seven averages in a row become

larger or slower, this is called "runs up" or

"runs down." Such an occurrence is unlikely for

a process that is in control, so this would be considered

a signal for an out-of-control situation.

Because the distribution of sample means (for sample size

of five or more) forms a normal distribution, one would

expect the X to reflect that pattern. A pattern such as

those below suggests the process is out of control.

Because the distribution of sample means (for sample size

of five or more) forms a normal distribution, one would

expect the X to reflect that pattern. A pattern such as

those below suggests the process is out of control.

Michael J. Cleary, Ph.D., is a professor emeritus at Wright

State University and founder of PQ Systems Inc. Letters

to the editor regarding this column can be e-mailed to letters@qualitydigest.com.

|