The Heat Is On

Michael J. Cleary, Ph.D.

mcleary@qualitydigest.com

Hy Sedrate, a quality assurance

specialist for St. Recover in the Long Run Hospital, has

noticed that the accuracy of his lab readings is higher

in cool weather than it is on hot days, even though the

lab is air-conditioned and doesn’t have an appreciable

difference in temperature from the rest of the hospital.

Nonetheless, the data are dramatic, and Sedrate wants to

demonstrate the pattern he’s observed so his boss

and the entire quality team can analyze the situation.

Sedrate collects data relating to defective lab readings

while tracking the daily high temperatures recorded by the

National Weather Service for his area. Without complex analysis,

he can see even from the raw data that the higher the temperature,

the greater the number of errors. In order to illustrate

the pattern that he’s observed, he decides to create

an individual moving range chart from the data.

After he’s produced the charts and examined them

for patterns, another quality specialist, Hap N. Stance,

insists that Sedrate has used the wrong statistical method.

Nevertheless, Stance can’t suggest an approach that

might be better. Is Sedrate correct in using an individual

moving range chart, or is there a better way to analyze

this data?

a. Sedrate should abandon his chart and take an Alka Seltzer.

It’s too hot outside to think.

b. An individual moving range chart provides insights about

the data that no other method can give.

c. Stance is on the right track but the wrong train. He

should advise Sedrate to use a scatter diagram to get the

best analysis of the data.

d. Because he already knows that there’s a relationship

between defects and temperature, Sedrate should select the

chart that will be most dramatic so he can impress the quality

team with his statistical prowess.

Answer c is the correct response.

A scatter diagram will indicate whether two variables--in

this case, temperature and inaccurate lab reports--are related

to each other, or whether there’s a correlation between

the two. If one of the variables appears to have an effect

on the other, then regression analysis will be appropriate.

Because Sedrate wants to establish whether there’s

a correlation, an individual moving range chart won’t

be of any help. (See Practical Tools for Continuous Improvement

Vol. I, Statistical Tools, by Jacqueline D. Graham, Ph.D.,

and Michael J. Cleary, Ph.D., pp. 298–311).

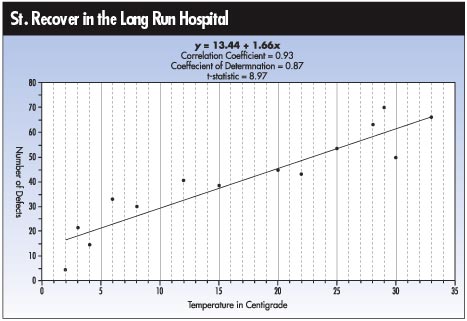

The same data is shown within the chart on page 20.

Because Sedrate assumes that temperature affects the number

of defects (rather than the other way around), temperature

becomes the independent variable, represented on the horizontal

axis. The number of defects becomes the dependent variable,

on the vertical axis. The line of best fit shows the relationship:

y = 13.44 + 1.66x

This means that as the temperature goes up, so does the

number of defects. A correlation coefficient of 0.93 suggests

a rather strong relationship between the two variables.

In addition, the t value of 8.969 suggests that there’s

indeed a statistical relationship between the number of

defects and temperature. But Sedrate should be encouraged

to study a little more statistics before approaching his

next challenge.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a professor emeritus of management science

at Wright State University in Dayton, Ohio. A 29-year professorship

in management science has enabled him to conduct extensive

research in expanding quality management methods. He’s

the author of several articles on quality management and

statistical process control. Letters to the editor regarding

this column can be sent to letters@qualitydigest.com.

|