New Groups Consider ISO Auditing Practices

New Groups Consider ISO Auditing Practices

The International Accreditation Forum, ISO/TC 176 and CASCO

have formed the ISO 9001 Advisory Group, a mutually representative

group to consider the credibility of ISO 9001 and its certification.

Under the guidance of IAF, the IAG is responsible for:

Monitoring the credibility of ISO 9001 for certification

and providing feedback to each of the component members

of the group

Providing a forum for discussion of user satisfaction and

creating action plans when complaints or indications of

concern are identified

Providing a forum for discussion of user satisfaction and

creating action plans when complaints or indications of

concern are identified

Identifying issues that indicate the need for official ISO/TC

176 interpretations to ISO 9001:2000 or specific IAF guidance

Identifying issues that indicate the need for official ISO/TC

176 interpretations to ISO 9001:2000 or specific IAF guidance

Providing feedback to ISO/TC 176 on the acceptance of its

standards and providing input for future revisions

Providing feedback to ISO/TC 176 on the acceptance of its

standards and providing input for future revisions

Acting as a basis for "shadow" committees on a

local or regional basis for ISO member bodies and accreditation

body members of IAF.

Acting as a basis for "shadow" committees on a

local or regional basis for ISO member bodies and accreditation

body members of IAF.

ISO/TC 176 is the committee responsible for forming the

ISO 9001 quality management system, and CASCO is the ISO

Committee on conformity assessment.

During a September meeting, the IAG identified a lack

of understanding of the process approach to auditing. ISO/TC

176 is currently initiating a revision of the Guidance on

the Process Approach, and the IAG has plans to develop specific

guidance on best practices for auditing to the new standard.

The IAG met in February to discuss actual and potential

threats to the credibility of ISO 9001. During the meeting,

the group reviewed the factors affecting ISO 9001 credibility,

compiled relevant initiatives by members of the IAG, performed

a gap analysis to identify problems not currently addressed

by IAF members, and assessed the progress of transition

to the new standard.

Additionally, IAF agreed to formalize the group's composition

to ensure a balance of interests from industry, accreditation

and certification bodies, auditing practitioners, ISO/TC

176, and CASCO.

The first meeting of the Good Auditing Practice group

also took place in February. GAP discussed the development

of practical guidelines on effective means of auditing against

ISO 9001:2000 for third-party registrars. These guidelines

will be compiled into a "how to" document with

practical examples, forms and other tools that address past

poor practices and recommended good practices.

The activities of IAG and GAP will parallel work already

underway by the IAF to encourage a competence-based approach

to accreditation audits. The overall direction for both

groups is toward maximizing the effectiveness of results-based

auditing.

The IAF is a global association of conformity assessment

accreditation bodies and other bodies interested in conformity

assessment. To learn more, visit www.iaf.nu.

IAF's Relationship with ISO

The International Accreditation Forum works in liaison

with the following four ISO technical committees:

ISO/TC 176--Scope includes standardization of generic quality

management systems and supporting technologies, and specific

standardization at the request of affected sectors.

ISO/TC 176--Scope includes standardization of generic quality

management systems and supporting technologies, and specific

standardization at the request of affected sectors.

ISO/TC 176/SC 2--A subcommittee of ISO/TC 176. The group

is directly responsible for 10 ISO standards.

ISO/TC 176/SC 2--A subcommittee of ISO/TC 176. The group

is directly responsible for 10 ISO standards.

ISO/TC 207--Responsible for standardization of environmental

tools and management systems.

ISO/TC 207--Responsible for standardization of environmental

tools and management systems.

CASCO--The ISO Committee on conformity assessment. CASCO's

responsibilities include studying the conformity assessment

of products, processes, services and management systems

to standards or other technical specifications; preparing

international guidelines and standards relating to testing,

inspection and certification of products, processes, and

services; assessing management systems, testing laboratories,

inspection bodies, certification bodies, accreditation bodies

and their operations; and other duties.

CASCO--The ISO Committee on conformity assessment. CASCO's

responsibilities include studying the conformity assessment

of products, processes, services and management systems

to standards or other technical specifications; preparing

international guidelines and standards relating to testing,

inspection and certification of products, processes, and

services; assessing management systems, testing laboratories,

inspection bodies, certification bodies, accreditation bodies

and their operations; and other duties.

Study Reveals Need for Vision Technology

Standards

The machine vision industry generated revenues of $1.12

billion in 2002 and estimates revenues of up to $2.62 billion

by 2009, according to a recent study conducted by the consulting

group Frost & Sullivan.

"World Machine Vision Inspection System Markets"

contends that because of this estimated growth, a common

standard for machine vision technology is needed. Experts

at Frost cite two major reasons to develop a common standard:

increasing system component capability options and making

systems more appealing to end-users.

"The lack of operating standards within the machine

vision industry creates difficulties in developing and operating

vision systems, and end-users often can't connect desired

components," explains Sunderraju Ramachandran, research

analyst at Frost & Sullivan. "Conflicts between

components, computer software and hardware technologies

and user interfaces reduce credibility for the industry

as a whole because there is no plug-and-play for generic

systems."

End-users want systems that contain more robust technology,

have greater potential applications and add value, the document

states. Also in demand are simpler user interfaces to allow

comfortable interaction with the system, regardless of the

level of technical knowledge. Other areas that need focus

include optical character- and pattern-recognition algorithms,

resolution and image mapping.

A major hurdle for machine vision technology is increasing

buyer awareness of the capabilities of vision systems and

eliminating consumer skepticism created by earlier, less

capable systems.

The study is organized by industry: automotive, electronics,

semiconductor, food, pharmaceutical and world vision systems

markets. Each section contains an overview of the state

of machine vision technology within that market, along with

revenue forecasts, demand analyses, market and technology

trends, and pricing trends.

Frost & Sullivan provides strategic growth consulting

and market analysis. To obtain a copy of "World Machine

Vision Inspection System Markets," call (877) 463-7678

or visit www.testandmeasurement.frost.com.

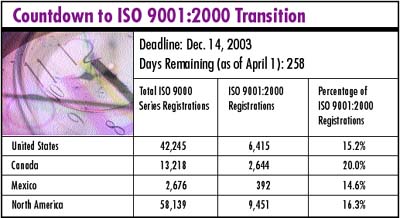

Countdown to ISO 9001:2000 Transition

Six Sigma Success for Staffing Services

By now, anyone even remotely interested in quality knows

that Six Sigma is the hottest defect-reducing tool out there.

Beginning with Motorola, the methodology has worked its

way through a host of industries, namely manufacturing and

service organizations.

As Six Sigma steadily penetrates U.S. organizations, many

are hesitant to begin the implementation process, thinking

that Six Sigma doesn't apply to them. Many organizations

assume that Six Sigma won't work because it has never before

been implemented in their industry. Other organizations,

such as Volt Services Group, are proving them wrong.

Volt Services Group, the staffing business unit of Volt

Information Sciences Inc., has announced that it is the

first leading staffing company to implement Six Sigma.

"Volt uses Six Sigma to consistently quantify and

track process improvements, maximize employee productivity,

improve service delivery, enhance our organizational focus

and efficiency, and accelerate the adoption of new staffing

technologies," explains Jerome Shaw, executive vice

president and co-founder of Volt Information Sciences. "Many

of our top customers are Six Sigma companies as well. Six

Sigma will give us the tools we need to align Volt's service

strategies to our customers' workforce objectives."

Volt's Six Sigma initiative began in August 2002 with

the appointment of Excelsis Magno, a certified Master Black

Belt, to the position of director of business process improvement.

Magno is responsible for executing Volt's Six Sigma strategy,

developing necessary tools and overseeing the implementation

of the initiative.

So far, Volt has reached several milestones, including

the formation and training of its senior executive leadership

council for Six Sigma, communication of the Six Sigma mission

to its more than 31,000 employees, and the identification

and acceptance of key projects.

Volt is also deploying and training individuals within

its organization as Black Belts, selected among the company's

highest performing employees.

Volt's staffing services segment fulfills information

technology and other technical, commercial and industrial

placement requirements on both a temporary and permanent

basis. For more information, visit www.volt.com.

ISO Considers Creating Social Responsibility

Standard

An advisory panel has recommended to the International

Organization for Standardization that it should consider

developing standards that address the social responsibility

of organizations.

To determine whether ISO should pursue creating social

responsibility standards, the advisory group recommended

that the organization develop a technical report surveying

the worldwide state of social responsibility codes, guidelines

and specifications. In addition, the group advocated a justification

study to prepare a management system guideline standard

that specifically includes a process for the self-declaration

of conformity and excludes conformity assessment involving

third-party certification.

The advisory panel is headed by Daniel Gagnier, chairman

of ISO/TC 207, the technical committee responsible for the

ISO 14000 series of standards. The panel comprises representatives

from various stakeholders, including businesses, government

regulators, trade unions and consumers. The provisional

working definition of social responsibility used by the

panel is "a balanced approach for organizations to

address economic, social and environmental issues in a way

that aims to benefit people, communities and society."

The recommendations were developed from the advisory group's

February meeting in Geneva and were reviewed by the ISO

council in March. The technical management board initially

convened the advisory group to examine whether standardization

would add value to already existing corporate social responsibility

programs.

Currently, Social Accountability International's SA8000

guidelines are broadly recognized as one of the strongest

social responsibility standards. Based on International

Labor Organization conventions and the United Nation's Declaration

of Human Rights and the U.N. Convention on Rights of the

Child, the standard covers nine issues related to social

responsibility: child labor, forced labor, health and safety,

freedom of association and the right to collective bargaining,

discrimination, discipline, working hours, compensation,

and management systems.

To learn more about ISO's actions toward a social responsibility

standard, visit www.iso.org.

For information about SA8000, visit www.cepaa.org.

Financial

Organization Implements Six Sigma Alternative Financial

Organization Implements Six Sigma Alternative

Organizations have several options when choosing a quality

initiative: Six Sigma, ISO 9001, lean manufacturing, 5S,

quality circles, total quality management, kaizen…

the list could possibly fill this page. Perhaps the reason

there are so many quality improvement strategies is that

no one organization is exactly like another. And when companies

find that these prepackaged quality "shoes" simply

don't fit, many fashion their own using elements of existing

methods.

One such company is Countrywide Financial Corp., which

has developed and implemented FASTER, a proprietary project

management methodology modeled after Six Sigma. The company

asserts that FASTER is more accessible and applicable to

a financial services environment

FASTER is an acronym for the six steps in the life cycle

of a project: flow, analyze, solve, target, execute and

review.

"We anticipate Countrywide will, over time, realize

dramatic positive returns on our investment in FASTER,"

says Stanford L. Kurland, CEO. "Already, more than

500 projects have either been completed or are currently

underway."

The initiative provides tools for flowcharting, financial

analysis, structured meetings and management reports. It

has been adopted as the company standard to create a consistent

project management approach and a common language for employees

throughout the company.

Countrywide began its quality overhaul in January 2001,

when the company created its Performance Management Group

to spearhead strategic initiatives and formalize the company's

continuous improvement culture. The group developed the

FASTER methodology and trained employees on its application.

To learn more, visit www.countrywide.com.

|