Creative Thinking Helps Boeing Improve

Creative Thinking Helps Boeing Improve

In the spring of 2001, Larry

Larson and his colleague Bob Harms, who help build Boeing

757 airplanes in a factory near Seattle, found inspiration

for a new technology in a barnyard.

The two men were a part of the Boeing Co.’s Moonshine

Shop factory team, which was charged with discovering new

ways to decrease the costs and time required to build jetliners.

The Moonshine Shop gets its name from a Japanese lean manufacturing

philosophy that describes innovators developing new methods

late at night.

That spring, the two colleagues set off on a mission:

to find a simpler way to lift passenger seats from the factory

floor to the airplane door.

“We stopped at a carnival and watched the way Ferris

wheel seats move upward,” says Larson. “We looked

at ski lifts and considered roofing material loaders. We

went to see how sugar beets are loaded, and then we started

looking at farm equipment.”

Larson, who lives in rural Washington, had seen hay elevators

operating on neighboring farms--lifting individual hay bales

up into barn lofts. He knew the elevators had potential

for other uses and began visiting farm equipment dealers

and scrap yards to determine what was available.

The quest for one that could be modified to lift airplane

parts eventually led to Jack Wheatley, a rancher at the

Level Best Ranch. “Once Wheatley got our specifications,

he made a custom elevator in three days,” recalls

Larson.

To meet safety re-quirements, Harms added guards, top

and bottom fixtures, and tracks. The seats, which had wheels

attached, could be rolled onto the elevator and up to the

airplane.

Before the team’s efficiency efforts, the process

for loading passenger seats onto each airplane was cumbersome.

After seats arrived at Boeing, wheels were attached to each

seat and then delivered to the factory floor in a large

container. An overhead crane lifted the container from the

factory floor to a mezzanine. Seats were unloaded and rolled

through the airplane door, where the wheels were removed

before installation. The crane then delivered the empty

container to the factory floor, lifted the next container

onto the mezzanine. The entire process took 12 hours.

Using the hay loader construct, seats roll across the

floor to a holding area near the airplane. When it’s

time for installation, the seats are rolled to the seat

loader, which carries them up to the airplane door. The

process takes about two hours and eliminates the need for

cranes, a common factory bottleneck.

Once the 757 seat loader was in operation, word reached

the Boeing 737 assembly line in the next building. Soon,

members of the 737 Moonshine Shop team came to watch it

operate. The team members suggested some improvements to

the design, and it wasn’t long before they were using

one too.

Soon, Moonshine Shop teams for the Boeing 767 and 777

were working with Wheatley to build seat loaders based on

the previous prototypes. Two years later, the airplane production

lines are still using the modified farm machines. However,

continuous improvement is the goal of the Moonshine Shop

teams. Today, Harms is at work on a new seat loader that

will cut production time by eliminating the need for wheels

to be attached and removed from the seats before they’re

loaded.

“The philosophy of lean manufacturing is lifelong

improvement,” says Larson. “The need for innovation

never ends.”

New Standard Aims to Control Measurement

Processes

All

the quality processes in the world won’t help a company

whose measuring equipment and measurement processes are

out of control. Especially in manufacturing, maintaining

accuracy in measurement equipment is essential to ensuring

a quality end product. The ISO 9001:2000 standard calls

for organizations to have some form of measurement process

control in place. To help fulfill that requirement, the

International Organization for Standardization has released

ISO 10012:2003. All

the quality processes in the world won’t help a company

whose measuring equipment and measurement processes are

out of control. Especially in manufacturing, maintaining

accuracy in measurement equipment is essential to ensuring

a quality end product. The ISO 9001:2000 standard calls

for organizations to have some form of measurement process

control in place. To help fulfill that requirement, the

International Organization for Standardization has released

ISO 10012:2003.

The standard specifies the requirements for a measurement

management system that can be used by an organization performing

measurements as part of the overall quality management system,

and for ensuring that metrological requirements are met.

ISO 10012:2003 is useful for organizations struggling

to meet the requirements for measurement and measurement

process control in ISO 9001:2000 and ISO 14001:1996, although

its use is not a requirement of either. It can also be implemented

independently of these standards.

“ISO 10012 is intended to support meeting ISO 9001:2000

requirements for ensuring that a product conforms to specifications

by measuring the product’s physical characteristics,

such as length, width, thickness or other properties,”

says Dan Harper of the ISO working group that developed

the new standard.

The standard is intended for situations in which customers

and their suppliers need to specify product characteristics

as a technical reference guide or a tool in assessing and

auditing management systems. Its use in third-party certification

is not a requirement but a matter of agreement between the

interested parties.

The new standard replaces ISO 10012-1:1992 and ISO 10012-2:1997.

By merging the scopes of application of these earlier standards--equipment

and processes--in a unique document and integrating the

process-based approach of the ISO 9000:2000 series, ISO

10012 constitutes a comprehensive measurement management

system.

ISO 10012:2003, Measurement management systems--Requirements

for measurement processes and measuring equipment includes

requirement clauses followed by text boxes containing relevant

guidance. It was developed by ISO technical committee 176

and is available from ISO national member institutes. For

more information, visit www.iso.org.

Document Management Firm Implements Six

Sigma

IKON Office Solutions, the

largest independent distributor of document management products

and services in the United States, has plans to develop

and implement a Six Sigma initiative to drive increased

customer satisfaction and process improvement. IKON executive

Andrew Twadelle will lead the program as vice president

of Six Sigma.

“IKON is focused on the needs of today’s businesses,

and we are working to align our internal structure and our

processes to best meet our customers’ needs and grow

shareholder value,” says Matthew J. Espe, CEO of IKON.

“Six Sigma is an extremely powerful methodology that

has proven to increase customer satisfaction and overall

productivity in many of today’s leading businesses.

Six Sigma can be equally effective for IKON.”

Twadelle has experience in corporate governance, reengineering

and customer-focused process improvement. In his most recent

role as vice president of internal audit at IKON, he applied

corporate governance practices throughout IKON while also

driving key business initiatives and process changes for

the company. Prior to joining IKON, Twadelle was director

of enterprise risk services at Deloitte & Touche LLP,

where he worked with Fortune 500 clients to identify and

manage risk related to strategic, tactical, process and

system areas.

IKON veteran Neil Daniels will take over Twadelle’s

previous position as vice president of internal audit. Daniels

will lead IKON’s efforts to support efficient operations,

accurate financial reporting and compliance with regulations.

IKON Office Solutions is a leading provider of products

and services that help businesses manage document workflow

and increase efficiency. Learn more at www.ikon.com.

Interoperability Could Save the Auto Industry

Millions

One of the most common reasons

for slow manufacturing processes is miscommunication. However,

with the aid of Internet technology, this problem is being

addressed by many industries looking to speed production.

In particular, the automotive industry is the subject of

an interoperability project that could save millions of

dollars per year.

The Automotive Industry Action Group is exploring the

interoperability of automated inventory visibility systems

that would allow companies to seamlessly communicate demand

throughout the supply chain, resulting in an estimated net

savings of $225 million, according to the Inventory Visibility

and Interoperability project team at AIAG.

The IV&I project, sponsored by AIAG, the Original

Equipment Supplier Association, and Odette, an industry

association of European automotive manufacturers and suppliers,

will eliminate the need for companies to maintain costly

multiple software applications to support making inventory

replenishment decisions.

“Our focus is to provide value for the automotive

supply chain,” says Linda Plawecki, AIAG’s executive

director. “Our members see the clear need for open

standards and are willing to provide the resources to accomplish

it, so we’ve put this project on the fast track.”

Many tier 1 and tier 2 automotive suppliers are in the

process of implementing Web-based inventory visibility tools.

In addition, some OEMs have developed their own fulfillment

tools. Suppliers are often required to subscribe to and

support multiple tools, increasing their operations cost

and complexity.

“In today’s uncertain economic environment,

companies may be trying to trim budgets here and there while

wasting hundreds of millions of dollars on processes,”

says Darrell Schwartz of Metaldyne, an AIAG member company.

“By tackling the complex issue of inventory visibility

and interoperability, AIAG is addressing a key process issue

that will yield cost savings throughout the supply chain.”

Upon completion of the IV&I project, customers and

suppliers will be able to view and share identical business

information regardless of the software packages used by

either company. Data will be shared in a secure environment

using a standard automotive electronic format that can be

accessed using a browser or integrated into a company’s

applications. AIAG has also entered into a strategic alliance

with the National Institute of Standards and Technology

for this project. The NIST interoperability test bed will

be used for the proof-of-concept phase of this project later

this year.

For more information, visit www.aiag.org.

Biotech Firms Can Have Too Few or Too

Many Quality Personnel

Amid

increased regulation and the U.S. Food and Drug Administration’s

scrutiny over manufacturing and quality control processes,

global pharmaceutical and biotech leaders must find an even

balance between devoting too many or too few resources to

quality management. A recent study by pharmaceutical research

firm Best Practices LLC, claims that top performing pharmaceutical

companies have found that balance by hiring the right number

of top-performing personnel. Amid

increased regulation and the U.S. Food and Drug Administration’s

scrutiny over manufacturing and quality control processes,

global pharmaceutical and biotech leaders must find an even

balance between devoting too many or too few resources to

quality management. A recent study by pharmaceutical research

firm Best Practices LLC, claims that top performing pharmaceutical

companies have found that balance by hiring the right number

of top-performing personnel.

The study has identified some of the latest benchmark

trends in quality organizations, staffing and execution.

The findings highlight how leading pharmaceutical and biotech

companies utilize appropriate quality staffing and effective

structures to optimize productivity, reduce costly rework,

increase operational improvements and boost bottom-line

savings. For example, extensive research uncovered these

quality staffing findings:

The average number of quality personnel per plant ranges

from 33 to 131, a fourfold difference that significantly

affects costs.

The average number of quality personnel per plant ranges

from 33 to 131, a fourfold difference that significantly

affects costs.

Benchmark companies cross-train other employees to increase

the number of qualified employees and reduce dependence

on quality personnel.

Benchmark companies cross-train other employees to increase

the number of qualified employees and reduce dependence

on quality personnel.

“We’ve found that organizations can have too

few or too many quality personnel,” says Keith Symmers,

vice president of Best Practices LLC. “Additionally,

it’s been demonstrated that you cannot hire your way

out of poor quality. The right staffing levels accompanied

with robust quality training for the whole company and supporting

systems are essential in avoiding the pain of poorly executing

on the quality front.”

The leading practices, lessons learned and benchmark metrics

in this consulting analysis were drawn from interviews and

benchmarking surveys with quality executives at nine leading

pharmaceutical organizations. The study describes the organizations’

tactics, including tips for managing quality control personnel,

sample rooms, team-based work stations and lab supervisors.

For more information, go to www.best-in-class.com/q/q27.htm.

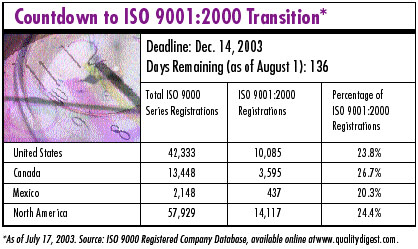

Note: These numbers are artificially low, perhaps due

to outdated registrar data. This month’s Quality Digest

ISO 9001:2000 Transition Survey shows that 53 percent of

registered companies have transitioned to ISO 9001:2000.

For more information, see “ISO 9001:2000 Transition

Survey.”

INDUSTRY NEWS

DNV Certification Inc. has been approved by the California

Energy Commission and California Climate Action Registry

to provide independent certification of greenhouse-gas emissions

on behalf of CCAR participants.

The CCAR has certified DNV to measure GHG emissions, establish

baseline emissions and report annual emission results. DNV

is the second company to become a participant registrar.

For more information about DNV Certification, visit www.dnvcert.com/cc.

The Yale New Haven Health System has selected Instantis

to automate its Six Sigma project management and knowledge

sharing across the organization.

Instantis’ Six Sigma project lifecycle management

system will augment a Six Sigma improvement methodology

introduced to YNHHS in 2001. The program, targeted at delivering

safer, higher quality care and service to patients and other

customers while managing resources more efficiently, will

use Instantis’ application to improve Six Sigma idea

selection, project management and tracking, communication

of results, knowledge sharing and best practices. Learn

more at www.instantis.com.

FARO Technologies Inc. has released two of its portable

coordinate measuring machines in a single package, uniting

the company’s platinum FaroArm control station, a

long-reach probe featuring six degrees of freedom, with

the FARO Laser Tracker Si, with a range of 230 ft. Both

systems share the same CAM2 Measure software.

The FARO Combo sells for $20,000 less than the cost of

purchasing the technology separately. “Combining these

two technologies creates an immediate ROI,” says FARO

hardware product manager Shaun Mymudes. “For the first

time, manufacturers have the ability to measure anything

of any size, anywhere, simultaneously, with no line-of-sight

limitations, and all on the same software interface.”

Details are available at www.faro.com.

Software

Certifications has initiated a new program to crack down

on communication and control failures within large systems-development

projects, the primary responsibilities of software project

managers. Software

Certifications has initiated a new program to crack down

on communication and control failures within large systems-development

projects, the primary responsibilities of software project

managers.

The certified software project manager program is available

to qualified individuals under a skills and experience provision.

Examinations will commence Jan. 1, 2005. The program will

be sponsored by the Quality Assurance Institute certification

board and administered by the QAI professional certification

division. For more information, visit www.softwarecertifications.com.

Two direct mail processing facilities of Harte-Hanks Inc.

have been certified by the United States Postal Service

for compliance with its Mail Preparation Total Quality Management

program. The facilities are the first of their kind to earn

the MPTQM quality distinction.

The MPTQM process is a systematic prevention-based approach

for managing the quality of the mail preparation process.

Formulated by the USPS and an advisory group of mailers

and mail service companies beginning in 1995, MPTQM certification

is based on performance criteria related to ISO 9000, total

quality management and the Baldrige National Quality Program.

For more information, visit www.harte-hanks.com.

Troemner Inc., a provider of weight, mass and standards

calibration services, now offers temperature calibration

services for resistance-type measuring devices. Troemner

can tailor a temperature calibration to suit SPRTs, RTDs

and thermistors, from 196° to 700° C. Primary fixed-point

calibrations are available for calibrating in-house temperature

standards and high-precision devices. Secondary comparison

calibrations for less precise temperature devices are also

available.

The temperature laboratory is ISO/IEC 17025-compliant

with primary standards directly traceable to NIST. Troemner

is currently applying for NVLAP accreditation. For more

information, visit www.troemner.com.

The corporate headquarters and primary production facility

of Metrologic Instruments Inc. have been registered to ISO

9001:2000. The registration is part of a list of goals that

included the launch of several new point-of-sale and industrial

products intended to increase Metrologic’s market

share and sales.

Metrologic Instruments manufactures imaging systems using

laser, holographic and vision-based technologies, high-speed

automated data capture solutions and bar code scanners.

Learn more at www.metrologic.com.

|