by Chad Kymal and Dave Watkins E

ver since the first edition of ISO/TS 16949 was released, automotive suppliers have wondered if it would eventually replace the Big Three's QS-9000 requirement. Faced with the very real

possibility that they might be required to register to ISO/TS 16949, automotive suppliers would be well-advised to take a serious look at how they might begin the transition from QS-9000 to

ISO/TS 16949. Recently, we had the opportunity to see a draft of the second edition of ISO/TS 16949:2002. Although changes might still be made before this edition is published

as a revised ISO/TS 16949 document, this latest draft is the one that will circulate within the ISO Technical Committee 176 for a ballot of approval. The issue remains whether

and when automotive suppliers should consider switching from QS-9000 to ISO/TS 16949. While pondering this, suppliers must also consider two related questions: What's the future of automotive

sector-specific quality management system requirements? And, if they are going to switch, what should organizations do to plan for the transition?

ISO/Technical Specification 16949:2002 Quality management systems--Automotive suppliers--Particular requirements for the application of ISO 9001:2000 will fully align

with ISO 9001:2000. Also, the International Automotive Task Force's additions contained in the first edition of ISO/TS

16949, with only a few minor edits, have been mapped directly to ISO 9001:2000's structure. In essence, the challenge for QS-9000-registered companies will be to implement

methodologies to help them become customer- and process-focused. The key question then is: What steps should QS-9000-registered companies take to implement ISO/TS 16949:2002?

It would be premature to discuss details of the latest draft until all of the elements of the equation are known, especially the customer-specific requirements of OEMs.

However, by using ISO 9001:2000 and ISO/TS 16949:1999, there are four steps, plus an alternative approach, that your organization can take to be ready for the future.

Step one: Create a process map and understand customer requirements

Before you do anything else, study your organization. Follow the product development process and interview all personnel involved with it. To create a process map, you must

identify all of your organization's key activities, from new-product development to production all the way to shipping and delivery procedures. To ensure that the process

map you end up with is useful to your organization, identify all the support processes that affect your products' development and delivery, as illustrated.

Next, determine who your customers are. Decide if the QMS you create will only support customers for your product or if it will also satisfy the requirements of all your

organization's interested parties. The implications of this decision are immense. The processes needed to support these interested parties (e.g., owners/investors, lenders,

personnel, suppliers/partners and the community) may result in incorporating even more processes into your process map. You'll find useful guidance and recommendations for

this topic in ISO 9004:2000, clause 5.2, Management responsibility--Needs and expectations of interested parties.

It's important to understand the needs and expectations of your customers and interested parties. It will help answer the question, "What process, or set of processes,

will satisfy these expectations?" In doing so, you might find that the organization actually needs to create new processes.

Finally, check to see whether the process map includes every ISO 9001:2000 process. Do you have processes for identifying and analyzing customer expectations and needs

regarding your organization's capabilities? Are there processes for capturing and analyzing customer expectations?

Step two: Conduct a gap analysis of the existing system

Examine the documentation structure behind your organization's QMS. Have you documented the necessary processes? If so, verify that you have the documents needed

to ensure the effective planning, operation and control of your processes, as is required by subclause 4.2.1(d), Documentation requirements--General.

Also, determine if both the operation and control of these processes are effective per clause 4.1(c), Quality management system--General requirements. Taking these steps,

which requires asking questions about the existing QMS, should clarify your organization's documentation needs for satisfying customers and interested parties.

ISO 9001:2000 doesn't restrict an organization from documenting any process that is part of its QMS, but it does require six procedures, which are already required by

QS-9000 and ISO/TS 16949:1999, to be documented. Ultimately, the IATF has retained documentation requirements in ISO/TS 16949:2002 beyond those required by ISO 9001:2000.

Once you've taken the aforementioned steps, it's time to conduct an audit or gap analysis to prepare for revising your QS-9000-registered quality system to conform

with ISO/TS 16949:2002's requirements. The second edition's changes to automotive requirements are minimal. So using ISO/TS 16949:1999 and ISO 9001:2000 (we

recommend using ISO 9004:2000 as well) will provide you with the right criteria against which to measure your organization's QMS.

Because your greatest adjustment will be from QS-9000 to ISO/TS 16949, we've laid out the key differences between ISO/TS 16949 and QS-9000 in the table on page 33 to

show you where you need to focus. Once the gaps have been identified, your organization should develop a timing plan for implementing ISO/TS 16949:2002. This

requires two methodologies. The first, the business operating system process, links customer expectations to objectives and then to key processes. The second, the process

review methodology, institutionalizes continual improvement at the process level. Step three: Implement a BOS

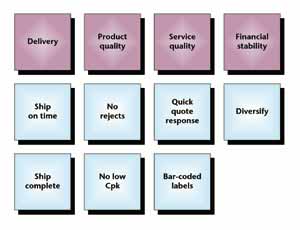

The first step in implementing a business operating system involves identifying customer and interested-party expectations. Begin by listing, grouping and rating

expectations. This allows better alignment of customers' and interested parties' expectations with processes and metrics, as shown below.

Another key step in this methodology is using alignment charts to link each expectation category to the key processes and process measurables that must be measured and

monitored to satisfy the requirements of ISO 9001:2000's clause 4.1(e) and subclause 8.2.3, Monitoring and measurement of processes.

An example of an alignment chart that would be used by an automotive supplier to satisfy critical, value-added requirements of ISO/TS 16949 and improve its QMS's

effectiveness and customer satisfaction appears above. To satisfy ISO 9001:2000's subclause 5.4.1, Planning--Quality objectives, your

organization should benchmark to determine what its short- and long-term objectives should be. Your organization's improvement plans of meeting overall objectives, per

subclause 5.4.2, Quality management system planning, are accomplished by using a business operating system.

Step four: Implement the PRM Process review methodology is a method of documenting and controlling QMS

processes. It takes the processes from the process map and your organization's documentation and applies process flows, process failure mode and effects analyses,

and control plans to ensure that your documentation is effective and that your QMS processes are under control.

The tools and methods used for QS-9000 compliance of production processes are used in process review methodology for analyzing and controlling nonmanufacturing

processes. An organization doesn't need to document every process using process flows, only those that require documentation to ensure the effective planning, operation

and control of its processes. However, each process uses a process failure mode and effects analysis to document

problems, or "failure modes," and recommend actions to be taken. In this manner, small improvements at the process level can be identified and documented, as required by

clause 4.1(f) and subclause 8.2.3. A control plan is used at the process level for planning the types of controls required to ensure a process's outputs meet the intended

outcome of that process. This document links the business operating system process measurables and the process review methodology approach. Implement ISO/TS 16949:2002 One of the greatest challenges--and benefits--of implementing ISO/TS 16949:2002 is

that it will require a QS-9000-registered organization to become both customer- and process-focused. The other major changes between ISO 9001:1994 and ISO 9001:2000

(e.g., customer satisfaction, continuous improvement and data analysis) are already required by QS-9000; so these transition elements are already addressed.

Becoming customer-focused requires an organization to implement a methodology like the business operating system process. Becoming process-focused re quires a process map and an implementation process like process review methodology. However, they both

require an organizational culture change. The application of cross-functional management, matrix organizations and process-based organizational requirements may be considered,

but they aren't required by ISO/TS 16949:1999, nor will they be in its second edition. quires a process map and an implementation process like process review methodology. However, they both

require an organizational culture change. The application of cross-functional management, matrix organizations and process-based organizational requirements may be considered,

but they aren't required by ISO/TS 16949:1999, nor will they be in its second edition. Organizations are encouraged to understand and learn more about

ISO 9001:2000, which, for most companies, will require more adjustment and cultural change than ISO/TS 16949. Organizations needn't wait until 2002 to implement what is,

in effect, ISO/TS 16949:2002--even though registration can't yet be achieved.

An alternative: the minimalist approach An alternative approach that some organizations can take requires no change. It's the

alternative to what is clearly a commitment of resources involving some effort by management to improve the organization. With this approach, an organization makes

changes only to its quality manual by rewriting it to include the QMS's scope and any exclusions claimed by the organization and by adding a process map that shows a

description of the interaction between the procedures of the quality management system. This process map would also reference the procedures in the procedures manual.

No new procedures would need to be added because a QS-9000-conforming system should already have documentation for the six procedures required by ISO 9001:2000.

If the minimalist approach is taken, an organization will need to consider the following:  Is its documentation written around the organization's processes? In other words,

its procedures manual shouldn't be written in response to the elements of QS-9000 but rather around its business processes. Is its documentation written around the organization's processes? In other words,

its procedures manual shouldn't be written in response to the elements of QS-9000 but rather around its business processes.

All the processes required to meet "customer and applicable regulatory

requirements" (clause 1.2, Scope--Application) should be identified within the process map (clause 4.1[a]). Has the organization identified the processes it needs to satisfy all

customer and regulatory needs and expectations? All the processes required to meet "customer and applicable regulatory

requirements" (clause 1.2, Scope--Application) should be identified within the process map (clause 4.1[a]). Has the organization identified the processes it needs to satisfy all

customer and regulatory needs and expectations?

If the process map shows that the contract review process flows into the program management process in advanced product quality planning, then the contract review

procedure needs to clearly identify how it hands off to the program management procedure. The inputs and outputs between the two processes need to be carefully

defined. This link should be evident between all processes in the process map.

If the process map shows that the contract review process flows into the program management process in advanced product quality planning, then the contract review

procedure needs to clearly identify how it hands off to the program management procedure. The inputs and outputs between the two processes need to be carefully

defined. This link should be evident between all processes in the process map.

Each process, including training and management review, must be monitored, measured and analyzed, as per the requirements of clause 4.1(e). Each process, including training and management review, must be monitored, measured and analyzed, as per the requirements of clause 4.1(e).

A word of warning: Organizations and auditors must be careful to avoid the minimalist approach's biggest pitfall, which is, in effect, that no improvement will be evident in

such a system. More important, the organization won't make any progress toward becoming customer- or process-focused, which could be detrimental in the long term,

even if the OEMs it supplies never require ISO/TS 16949:2002 registration. About the authors

Chad Kymal is CEO of Omnex Inc., an international consulting, training and software organization specializing in business quality improvement methodologies. Kymal assists

organizations worldwide as a consultant and trainer. David Watkins is president of Omnex Inc. and is a senior trainer/consultant. He has a

wide range of international experience, integrating QMSs and other management systems to enhance performance. E-mail the authors at ckymal@qualitydigest.com .

This article has been reprinted, with modifications, from the August 2001 issue of "The Informed Outlook." |