| by Jeff Walker

In a perfect world, every CMM would be built entirely

of “unobtanium,” a well-known fictional aerospace

material that possesses exactly the combination of properties

needed to achieve some otherwise unachievable goal. The

variety used in the perfect CMM has a zero coefficient

of thermal expansion, infinite stiffness and no mass. Housed

in an absolute vacuum at zero K and operated by tractor

beams, which induce neither heat nor stress into the structure,

it would be the ideal CMM. Unfortunately, we don’t

live in a perfect world.

Our CMMs are subject to myriad error-inducing factors,

including dynamic thermal and mechanical stresses, inconsistent

and nonlinear material responses, inappropriate human inputs,

and--perhaps the greatest error-inducer of all--economics.

CMM builders counter these error-inducers with a toolbox

that includes good design, carefully selected materials

and sophisticated software-based compensation systems--but

it’s an ongoing, uphill battle.

Because we live in the computer age, CMM designs in the

past few years have emphasized software compensation tools.

Great strides have been made and continue to be

made in this arena. But as these tools get better and better,

the limits of their ability to improve CMM performance also

become clearer.

It’s now possible, for example, to compensate for

thermal errors in the entire structure of a CMM, all the

way from the baseplate to the very tip of the probe. Moreover,

today’s best software can place the virtual origin

point for thermal expansion calculations anywhere on the

machine--not just at the mechanical datum point--to minimize

distance-related translation errors. Compensation for mechanical

errors is equally sophisticated.

Compensation algorithms are very good and getting better,

but they’re ultimately discrete digital systems applied

to a dynamic analog reality. The fit is not, cannot, and

never will be perfect.

To make matters even more difficult, random influences

like thermistor tolerances and thermal response variations

within individual samples of the same material are also

present in the real world. In practice, these factors produce

an inescapable residual error that can be as high as 10

percent.

Considering that the coefficient of thermal expansion

for aluminum is nominally 23 ppm per degree Celsius, a

1° C change in temperature can produce an uncontrolled

and uncontrollable potential compensation error of 2.3 µm

in just a 1 m length. More costly components and more frequent,

time-consuming calibration routines can reduce the residual

error, but it can never be totally eliminated because it’s

inherent in the compensation process itself.

Today, we’re beginning to recognize the ultimate

limits of software compensation, and tomorrow we’ll

be bumping hard against them. In the future, the gains

from this technology will be progressively smaller while

the cost of each increment in terms of hardware expense

and machine utilization will be significantly higher.

If software compensation appears to be reaching its practical

limits, what else can be done to improve the performance

of today’s and tomorrow’s CMMs? The answer

is most likely a return to the basics of engineering a

stiffer, more stable and smoother operating platform that

will minimize the amount of compensation required in the

first place.

That process will include the use of new materials, better

bearings and more sophisticated designs for all of the

components and subsystems of a CMM. This will be complicated

by the need to achieve higher performance at a lower relative

cost while providing more usable uptime and greater application

flexibility to the CMM consumer. It’s a tall order.

When it appeared that software compensation would be

the ultimate solution to the problem of thermal growth

in CMM components, aluminum became a favorite engineering

material with many machine builders. Relatively stiff,

light, easily machined and inexpensive, aluminum’s

only major flaw is its high thermal response rate. This

is a negative that everyone believed software compensation

would easily overcome.

Today we know better. Most high-end CMMs, and a growing

number of mid-range and even low-end machines, now use

some form of ceramic or composite for the critical bridge

beam structure. The reason is that ceramics are extremely

stiff, relatively light and thermally stable. One of the

better ceramic materials, polycrystalline aluminum oxide,

is a full 330 percent stiffer than aluminum, yet it’s

only 32 percent heavier and has less than a quarter of

aluminum’s coefficient of thermal expansion.

Assuming the same 10 percent residual error in the software

compensation system discussed earlier, a ceramic beam would

have a compensation error of only 0.6 µm in the same

1 m length, whereas aluminum has an error of 2.3 µm.

It’s still not perfect but much smaller and therefore

much less detrimental to the overall accuracy of the measurement

being taken.

But thermal growth isn’t the only stability issue

in CMM design. Dimensional changes related to both static

and dynamic mechanical stresses must also be considered

and compensated for. Unless they’re somehow relieved,

every material has some level of stress locked into its

crystalline and/or mechanical structure during its creation

or fabrication.

In machined or fabricated metallic components, these

stresses can be significant, even after artificial stress-relief

processing. In the case of natural materials like granite,

such stresses are negligible because of millions of years

of natural stress relief. That is one

of the reasons granite is the universally preferred material

for CMM bases. Modern polycrystalline ceramics fall somewhere

in between but are much closer to granite in natural stability

than they are to fabricated metallic components.

Stability is greatly influenced by good mechanical design,

particularly of the interfaces between components. So-called “kinematic” design

strategies strive to minimize--and ultimately eliminate--the

introduction of any stress into a structure at its various

mechanical interfaces. Although the subject of

kinematic design is too broad and detailed for this discussion,

it’s widely used in fixture design where the classic

3-2-1 location system provides an excellent example of

its application.

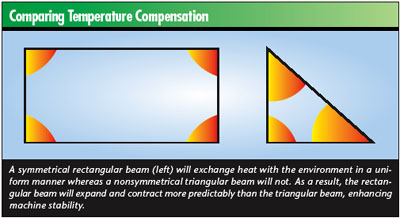

Achieving optimum stability in a structure such as a

CMM requires a detailed analysis of every component in

the structure. Even the shape of a beam can make a significant

difference in its thermal and dimensional performance.

For example, corners tend to be thermal stress points

because they heat and cool more quickly than flat surfaces.

As a result, rectangular structures tend to be more stable

than triangular structures because the corner-induced stresses

are symmetrical.

However, triangular structures are both lighter and less

expensive than rectangular structures of the same capacity

because they contain less material. They’re also

easier to fit with preloaded air bearings, as illustrated

on page 41.

A cost-driven design will choose triangular beams, whereas

performance-driven design will choose the more costly rectangular

beams. Over the long run, however, the more expensive design

will prove to be the more cost-effective because it’s

substantially more stable, and that means it requires fewer

recalibrations and delivers more usable uptime. In the

end, stability translates directly into reduced measurement

costs for the end-user.

Stiffness is the second major goal in CMM design, and

stiffness without mass is the essential characteristic

of CMM-style unobtanium. Materials with high stiffness-to-weight

ratios tend to minimize many of the mechanical errors inherent

in CMM design. Stiff, light real-world materials reduce

the mass of moving elements, permitting smaller drives,

less heat, shorter measuring cycles and lower costs.

The greater stiffness of ceramic beams shows up in analyses

of bridge behavior under acceleration. When accelerated,

the bridge beam is subjected to a directional deformation

force directly proportional to the acceleration. For an

aluminum beam, the resulting directional deformation is

nearly twice that of an equivalent ceramic beam, despite

the fact that the ceramic component is 32 percent heavier.

In practical terms, this means the ceramic beam can be

accelerated nearly twice as fast as the aluminum beam while

maintaining deformation within a comparable range. Greater

acceleration translates directly into shorter traverse

time and reduced cycle time for any given movement and

ultimately into a lower total cost for any given inspection

task.

Another material with greater stiffness than aluminum--200

percent, to be exact--is steel, which is used increasingly

in structural components such as support legs on advanced

CMMs. Because of its high

strength, steel--like ceramic materials--offers an opportunity

to design structures with enhanced performance and only

a small weight penalty compared to aluminum. And, like

ceramics, steel’s greater stiffness permits higher

acceleration and reduced cycle times and inspection costs.

Most CMMs today use air bearings to support moving components,

but all air bearings do not deliver the same level of performance.

The key influence on air bearing stiffness is the gap required

to support a given load--the smaller the gap, the stiffer

the bearing, all else being equal.

Conventional air bearings, the type used on most CMMs,

generally have several orifices placed in a pattern across

the otherwise smooth face of the bearing “pad.” These

orifices distribute pressurized air to lift the pad away

from the surface to create the bearing gap and support

the load.

There is another design, however. It has been found that

creating an annular groove on the pad face and connecting

it to one or more orifices using straight grooves produces

a more efficient bearing. The performance difference is

dramatic.

For a given load, surface area and air volume, the plain

bearing will have 3.5 times the gap of the grooved design.

Viewed from the stiffness perspective, with all else being

equal, the grooved bearing delivers 140,000 N/mm compared

to the plain-pad design’s 40,000 N/mm.

In the context of a CMM, this greater stiffness translates

directly into enhanced accuracy but also means the moving

elements can accommodate greater accelerations. As is the

case with stiffer materials, greater acceleration made

possible by stiffer bearings also means shorter cycles

and reduced measurement costs.

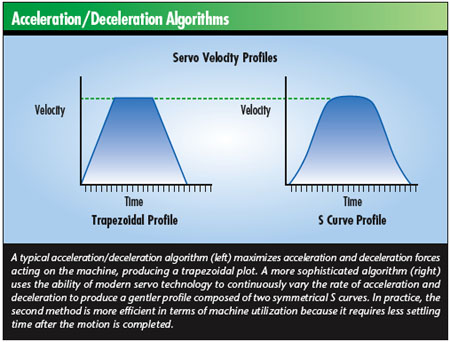

Although software-based compensation systems are rapidly

nearing the point of diminishing returns, the same cannot

be said for software-based motion control efforts. Today,

most CMMs use a simple acceleration/deceleration algorithm

that produces a trapezoidal plot. The strategy is to accelerate

to maximum velocity as quickly as possible, maintain that

velocity as long as possible, and then decelerate to zero

as quickly as possible, as illustrated below.

At first glance, this strategy might appear to deliver

optimum cycle times. After all, going as fast as possible

should be the key to getting from point A to point B in

the minimum amount of time; in a large, robust structure,

it may well be.

But CMMs are not large, beefy structures. For a CMM,

this strategy produces a substantial wait at the end of

the motion while the machine “settles down” and

dissipates the stresses and vibration generated by the

acceleration/deceleration process.

A better strategy is to control the motion to produce

a pair of gentle “S curves” during acceleration

and deceleration. In practice, this approach may add a

fraction of a second to the traverse time from point A

to point B, but this will be more than compensated for

by the reduction of waiting time once point B is reached.

In an intermittently used laboratory machine, the difference

may be negligible. But, in a production-monitoring application,

which fully utilizes the CMM’s capabilities, the

difference in cost-per-measurement can be substantial enough

to pay for the more sophisticated capabilities in a short

time.

No discussion of modern CMM design is complete without

some mention of scanning--unquestionably the technology

of the future. Because scanning is done “on the fly,” taking

measurements with all elements of the machine in motion,

it will quickly surpass the capability of software-based

compensation systems--unless the machine is designed from

the ground up to minimize the need for such compensation

systems. It’s already happening.

It’s time for the industry to get back to basics

and engineer CMMs that are optimally stable, stiff and

smooth, independent of the compensation system. The materials

exist, and none of them are “unobtanium.” The

technology exists. It’s time to shift the industry’s

primary focus away from compensation and back to sound

design.

Jeff Walker is manager of marketing and new products

at LK Metrology Systems Inc. in Brighton, Michigan.

|