| by Ellen Domb, Ph.D.

Six Sigma projects of all kinds frequently reach a point

where the analysis is done but the next step remains unclear.

In order to figure out what to do next, the project team

must employ those brainstorming and related process-improvement

tools recommended by Six Sigma and other methods, such

as total quality management and quality circles. However,

many of these tools depend on intuition and team members’ knowledge,

neither of which is reliable in a strictly scientific sense.1

Between 1946 and 1985, the Russian scientist G.S. Altshuller

and his colleagues developed a theory of inventive problem

solving known by the Russian acronym “TRIZ.” Based

on logic and data rather than intuition, TRIZ accelerates

a project team’s ability to solve problems. TRIZ

relies on the study of problem-and-solution patterns, not

an individual’s or group’s spontaneous creativity.

To develop the theory, Altshuller and his colleagues

analyzed more than 400,000 patents to discover the patterns

that predict breakthrough solutions to problems. TRIZ research

began with the hypothesis that universal principles of

invention underlie the creative innovations that advance

technology. Once these principles are identified and codified,

they can be taught and will help make the process of invention

more predictable.

Two basic truths in the TRIZ doctrine maintain that:

Somebody, someplace, has already solved any problem--or

one very similar to it. Somebody, someplace, has already solved any problem--or

one very similar to it.

Creativity

means finding that solution and adapting it to a current

problem. Creativity

means finding that solution and adapting it to a current

problem.

The research has proceeded in several stages. Four primary

findings indicate that:

Problems

and solutions are repeated across industries and sciences. Problems

and solutions are repeated across industries and sciences.

Classifying

the contradictions in a given problem makes it possible

to predict creative solutions to that problem. Classifying

the contradictions in a given problem makes it possible

to predict creative solutions to that problem.

Patterns of technical evolution are repeated across

industries and sciences. Patterns of technical evolution are repeated across

industries and sciences.

Creative innovations use scientific effects outside

the field in which they were developed.2 Creative innovations use scientific effects outside

the field in which they were developed.2

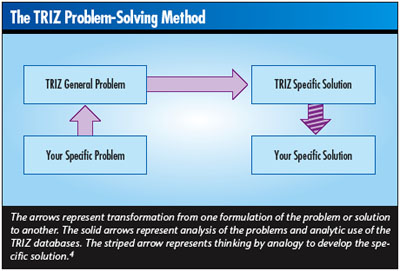

The practice of TRIZ consists of identifying problem-solving

patterns, identifying patterns of technical evolution,

identifying methods of using scientific effects, and applying

them to a specific situation confronting the developer,

as illustrated on page 56.

A powerful demonstration of this method can be found

in the pharmaceutical industry. Tailored bacteria are used

to cultivate human hormones, producing a superior product

to those refined from animal sources. To produce the hormone,

though, large quantities of tailored bacteria cells must

be cultured, the cells broken open and the cell walls removed.

A mechanical method for breaking the cells produced an

80-percent yield, but it was variable at best.3 More recently,

the yield had fallen to 65 percent; the pharmaceutical

industry wished to increase production to much higher yields.

The problem from a TRIZ standpoint is to find a way to

produce the product with no waste, at 100 percent yield

and without new complications. TRIZ theory states, “The

problem should solve itself.” A generic TRIZ solution,

based on patterns of technical evolution, replaces mechanical

devices with fields. This may seem very general, but it

led pharmaceutical researchers to analyze all the resources

available in the problem (e.g., the cells, cell walls,

surrounding fluid and its motion, the processing facility,

etc.). They concluded that three

specific solutions had high potentials for solving the

problem:

Cell walls could be broken by sound waves. Cell walls could be broken by sound waves.

Cell walls could be sheared open as they pass through

the processing facility. Cell walls could be sheared open as they pass through

the processing facility.

An enzyme in the fluid could “eat” cell

walls and release the contents at the desired time. An enzyme in the fluid could “eat” cell

walls and release the contents at the desired time.

All three methods had been tested successfully, and the

least expensive, highest-yield method was soon in production.

The general TRIZ solutions referred to on page 60 have

been developed during 65 years of research and organized

in many different ways. These include analytic methods

such as:

Ideal final result Ideal final result

Functional analysis and trimming Functional analysis and trimming

Locating zones of conflict (known to Six Sigma problem

solvers as root cause analysis) Locating zones of conflict (known to Six Sigma problem

solvers as root cause analysis)

Other solutions are more prescriptive and include:

The 40 principles of problem solving The 40 principles of problem solving

Separation principles Separation principles

Laws of technical evolution and technology forecasting Laws of technical evolution and technology forecasting

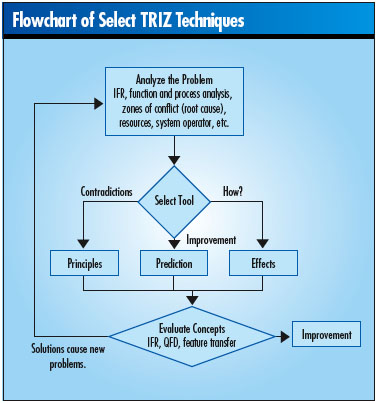

When solving any technical problem, one tool or many

can be used. The flowchart below illustrates

this.

The 40 principles of problem solving are TRIZ’s

most accessible “tool.”5 These principles repeat

across many fields as solutions to many general contradictions.

They also lie at the heart of many Six Sigma problems.

According to TRIZ methodology, contradictions should be

eliminated. The methodology recognizes two categories of

contradictions:

Technical contradictions. These are the classical engineering

tradeoffs in which the desired state can’t be reached

because something else in the system prevents it. In other

words, when something gets better, something else gets

worse. Examples of technical contradictions include the

following: Technical contradictions. These are the classical engineering

tradeoffs in which the desired state can’t be reached

because something else in the system prevents it. In other

words, when something gets better, something else gets

worse. Examples of technical contradictions include the

following:

- Product gets stronger (i.e., good), but the weight

increases (i.e., bad).

- Bandwidth increases (good) but requires more power

(bad).

- Service is customized to each customer (good), but

the service delivery system becomes complicated (bad).

- Automobile airbags deploy quickly to protect

the passenger (good), but the faster they deploy, the

more

likely they will injure or kill small or out-of-position

people (bad).

Physical contradictions. Also called “inherent” contradictions,

these include situations in which one object or system

has contradictory, opposite requirements. Everyday examples

abound: Physical contradictions. Also called “inherent” contradictions,

these include situations in which one object or system

has contradictory, opposite requirements. Everyday examples

abound:

- Surveillance aircraft should fly fast to their destinations,

but also slowly to collect data over the target.

- Software should be easy to use but include many complex

features and options.

- Coffee should be hot for enjoyable drinking but cool

enough to prevent burning consumers.

- Training should be thorough but not take any time.

- Airbags must inflate both quickly and slowly.

TRIZ includes 40 principles for solving technical/tradeoff

contradictions and four separation principles for solving

physical/inherent contradictions. Many problems

can be stated as both physical and technical contradictions.

In general, the most comprehensive solutions come from

the physical contradiction formulation, whereas the most

prescriptive solutions derive from the technical contradictions.

People usually learn to solve technical contradictions

first because the method is very concrete. Afterward, they

learn to solve physical contradictions, then use both methods

interchangeably,

depending on the problem.

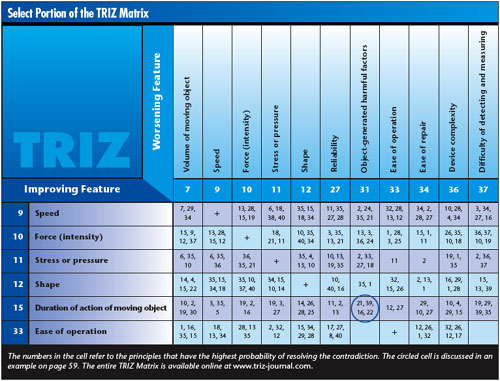

TRIZ research has classified 39 features for technical

contradictions. Once a contradiction is expressed in the

technical form (i.e., the tradeoff), the next step is to

locate specific features in the contradiction matrix.6 The

figure on below shows a piece of the matrix.

To use the matrix, find the row that most closely matches

the feature or parameter you’re improving in your

tradeoff and then the column that most closely matches

the feature or parameter that degrades it. The cell at

the intersection of that row and column will have several

numbers. These identify specific principles of invention

that are most likely to solve the problem, that is, to

lead to a breakthrough solution instead of a tradeoff.

For example, consider the proposal to change airbag inflation

speed to reduce injuries to small occupants. The tradeoff

is that injuries in high-speed accidents increase. Translating

this into TRIZ matrix terms, the parameter that improves

is “duration of action of a moving object” (row

15) and the parameter that worsens is “object-generated

harmful factors” (column 31). The circle in the figure

highlights the cell at the intersection and includes the

numbers 21, 39, 16 and 22. These are identifiers for four

principles of invention.

Usually the principles are accompanied by examples from

a variety of industries. The design or problem-solving

team uses the text, those examples and examples from its

own previous applications to develop a solution.

Consider the application of principle 21 to the airbag

example:

Principle 21: Skipping. Conduct a process or certain

stages of it (e.g., destructible, harmful or hazardous

operations) at high speed. For example: Principle 21: Skipping. Conduct a process or certain

stages of it (e.g., destructible, harmful or hazardous

operations) at high speed. For example:

- Use a high-speed dentist’s drill to avoid heating

tissue.

- Cut plastic faster than heat can propagate in the

material to avoid deforming the shape.

One solution to the airbag problem, then, would be to

inflate the bag faster than current practice, so that it’s

fully inflated when it impacts a small person. The “depowered” air

bag has been proposed as a solution of this type. By using

less power, the bag’s acceleration is less and injuries

will be reduced. Conversely, smaller bags with higher power

would reach full inflation sooner so that passengers would

be protected from accidents and not injured by the bag.

TRIZ outlines four ways to resolve physical or inherent

contradictions:

Separation in time Separation in time

Separation in space Separation in space

Coexistence of contradictory properties in different

subsystems Coexistence of contradictory properties in different

subsystems

Move

the problem to the super- or subsystem Move

the problem to the super- or subsystem

A very common Six Sigma transactional problem can be

expressed as an inherent contradiction: We want everyone

to understand all the Six Sigma methods so we can improve

all our processes, but we don’t want everyone to

stop working for the time required for training. In other

words, we want both a lot of training and no training.

Examining the separation principles, we see possible

solutions in all of them. For example, separation in time

suggests training Black Belts first, then having Black

Belts train other employees while working on projects.

TRIZ was developed from the study of patents, but the

underlying creative principles discovered apply to a wide

variety of transactional and product problems. Recent case

studies of actual situations include the following:

Transportation. Singapore needed to find a way to manage

automobile traffic on the Sentosa, the city’s entertainment

island. Applications of TRIZ methods developed eight families

of solutions.7 Transportation. Singapore needed to find a way to manage

automobile traffic on the Sentosa, the city’s entertainment

island. Applications of TRIZ methods developed eight families

of solutions.7

IT product development. DelCor Interactives International

doubled the value to the customer of its patient interview

system for optical offices. The company applied TRIZ feedback

and self-service principles8 to overall product

development. It also applied the principles of segmentation

(i.e., “taking

out” and “composite construction”) to

training and support. IT product development. DelCor Interactives International

doubled the value to the customer of its patient interview

system for optical offices. The company applied TRIZ feedback

and self-service principles8 to overall product

development. It also applied the principles of segmentation

(i.e., “taking

out” and “composite construction”) to

training and support.

Education. School administrators are enhancing their

creativity in dealing with situations ranging from allocating

budget for special education to building five schools using

funds for four, to improving racial harmony.9 Education. School administrators are enhancing their

creativity in dealing with situations ranging from allocating

budget for special education to building five schools using

funds for four, to improving racial harmony.9

Waste processing. Dairy farm operators could no longer

dry cow manure due to increased energy costs. TRIZ identified

the method used for concentrating fruit juice, which requires

no heat.10 Waste processing. Dairy farm operators could no longer

dry cow manure due to increased energy costs. TRIZ identified

the method used for concentrating fruit juice, which requires

no heat.10

Warranty cost reduction. Ford Motor Co. used TRIZ to

solve a persistent problem with squeaky windshields that

cost several million dollars each year.11 Previously,

the manufacturer used TRIZ to reduce idle vibration in

a small

car to less than one-third the initial value.12 Warranty cost reduction. Ford Motor Co. used TRIZ to

solve a persistent problem with squeaky windshields that

cost several million dollars each year.11 Previously,

the manufacturer used TRIZ to reduce idle vibration in

a small

car to less than one-third the initial value.12

Additionally, TRIZ works well with Six Sigma. As with

other tools in that methodology, TRIZ is procedural; it

can be used by individuals or teams, and helpful case studies

abound. The best way to explore TRIZ is to start with a

problem you haven’t solved satisfactorily and apply

these effective methods to it.

Ellen Domb, Ph.D., is the editor of The TRIZ Journal,

an online publication available at www.triz-journal.com,

and the principal TRIZ consultant for the PQR Group in

Upland, California. TRIZ is Domb’s sixth career:

She has been a physics professor, an aerospace engineer,

an engineering manager, a product-line general manager

and a strategic planning/quality improvement consultant.

References

1. Smith, Larry. 2001. www.asq.org/pub/sixsigma/past/vol1_issue1/evolution.html

Tennant, Geoff. 2003. “TRIZ for Six Sigma.” www.sixsigmatriz.com

2. Altshuller, Genrich. 1988. Translated by Anthony Williams.

Creativity as an Exact Science. Gordon and Breach, New

York.

3. Anderson, Wesley, Justin Farrell, and Karen Tate. 1997. “TRIZ

Applied to Solving Manufacturing Problems and Improvement.” Proceedings

of the third Annual International Total Product Development

Symposium, American Supplier Institute, Livonia, MI.

4. Rantanen, Kalevi, and Ellen Domb. 2002. Simplified

TRIZ. CRC Press, Boca Raton, Florida.

5. Domb, Ellen. 1997–2003. “Tutorial on

Contradictions.” The TRIZ Journal, www.triz-journal.com,

July 1997.

Altshuller, Genrich. 1988. Translated by Anthony Williams.

Creativity as an Exact Science. Gordon and Breach, New

York.

6. Domb, Ellen. 1997–2003. “Tutorial on

Contradictions” The TRIZ Journal, July, 1997.

Mann, Darrel, and Ellen Domb. “40 Principles for

Business, with Examples.” The TRIZ Journal, September

1999.

7. Zhang, Jun, Tan Kay-Chuan, and Chai Kah-Hin. “Systematic

Innovation In Service Design Through TRIZ.” The TRIZ

Journal, September 2003.

8. Domb, Ellen, and David Corbin. 1998. “QFD, TRIZ

and Entrepreneurial Initiative.” Proceedings of the

10th Quality Function Deployment Symposium, Novi, MI. Reprinted

in The TRIZ Journal, September 1998.

9. Hooper, Don, Kathy Aaron, Holly Dale, and Ellen Domb.

1998. “TRIZ in School District Administration.” The

TRIZ Journal, February 1998.

10. Raskin, Andy. 2003. “A Higher Plane of Problem

Solving.” Business 2.0 Magazine, June 2003.

11. Lynch, Michael. 1997. “Windshield/Backlight

Molding Squeak and Flutter (Buzz) Problem.” Proceedings

of the third Annual International Total Product Development

Symposium, American Supplier Institute, Livonia, MI. Reprinted

in The TRIZ Journal, January 1998.

12. Smith, Larry. 1996. “Using TRIZ to Reduce Vibration

During Idling.” Proceedings of the 12th Annual GOAL/QPC

Symposium, GOAL/QPC. Methuen, MA.

|