Five Easy Samples

Michael J. Cleary, Ph.D.

mcleary@qualitydigest.com

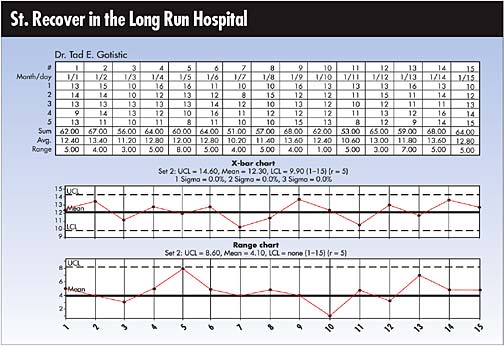

Dr. Tad E. Gotistic is confident

of his ability to instruct the emergency room nursing staff

at St. Recover in the Long Run Hospital in the fundamentals

of statistical process control, despite the fact that he

understands how to use X-bar and R charts but little else

in the way of statistical applications. However, he assumes

that the staff doesn't know as much as he does, and that

gives him an advantage. At least, that has always been the

case whenever he's had to prove his knowledge in a variety

of areas.

During the seminar in which Gotistic learned about charting,

the instructor provided an example using 15 samples of five

each, and Gotistic employs the same example when instructing

the nursing staff. Illustrated below is the chart he uses

in the class.

Gotistic created X-bar and R charts and was deeply involved

in deriving control charts when one of the nurses asked

why he'd selected a sample size of five. "Why not six

or seven or even 10?" This nurse had, in fact, also

participated in a seminar that offered an overview of SPC,

and the instructor had used a sample size of five in that

instance as well.

Gotistic had a ready answer, asserting that selecting

a sample size of five was required for statistical precision,

obliquely suggesting that any other sample size would be

flawed in its statistical calculations. "Trust me,"

he said, "This is statistically sound."

Why is using a sample size of five conventional practice?

a. It's grounded in statistical accuracy, as Gotistic asserts.

b. Using a sample size of five is the most economical choice.

c. A sample size of five renders the arithmetical calculations

more convenient.

d. A sample size of at least five creates validity, but

there's no magic in the number itself.

Answer c is correct. A sample size of five allows for a

shortcut to calculate the average. Five is the conventional

sample size not because of its link to any statistical principle,

but because it makes calculations more convenient.

By taking the sum of the samples, multiplying by two and

moving the decimal point one place to the left, the same

result ensues, as illustrated:

Moving the decimal one place to the left generates 12.4.

Remember that the control chart was developed during the

1930s, long before affordable calculators or PCs were available

for statistical calculations.

By the way, don't confuse your grade-school kids by introducing

them to this "new" way of calculating averages.

This method works only if the sample size is five.

Michael J. Cleary, Ph.D., founder and president of

PQ Systems Inc., is a noted authority in the field of quality

management and a professor emeritus of management science

at Wright State University in Dayton, Ohio. A 29-year professorship

in management science has enabled Cleary to conduct extensive

research and garner valuable experience in expanding quality

management methods. He has published articles on quality

management and statistical process control in a variety

of academic and professional journals. Letters to the editor

regarding this column can be sent to letters@qualitydigest.com.

|