by Charles Rastle and Julie Fraser

Using Six Sigma initiatives

to focus on improving the performance of business and manufacturing

processes isn’t a new concept. But a growing number

of manufacturers seeking to stay competitive and improve

profitability are, instead, turning to Six Sigma to provide

stronger value to customers. As a structured and fact-based

means of achieving continuous improvement, Six Sigma programs

need accurate data to analyze current performance issues

and their root causes. Measuring improvement--in terms of

defects per million, for example--requires accurate data.

Unfortunately, some Six Sigma programs get bogged down

in the area of data collection, particularly when collecting

information related to production, fulfillment and service

operations. Sometimes, Six Sigma teams--whether comprising

trained Black Belts, Green Belts or other employees--spend

significant time manually gathering data that they aren’t

confident is correct, which can cause justifiable frustration.

If the gathered data has built-in bias at the source or

is subject to interpretation, the results of analysis will

be suspect. At the very least, progress will be slow, which

can blunt support and momentum. Furthermore, manual data

collection is inherently error-prone, so an analysis may

be skewed by the Six Sigma team itself.

Preventing Six Sigma programs from withering due to a

lack of rich and accurate data requires sound information

systems. Ideally, these information systems should gather

data automatically at the source of an activity, which would

avoid data-source inaccuracies as well as errors potentially

resulting from human interpretation or filtering.

Six Sigma teams can benefit even more from data available

in a form that already correlates processes to products

and customer orders. In a production plant setting, a manufacturing

execution system is designed to provide just such data.

As an MES guides the execution of production processes,

it can also gather detailed data about the process, materials

and production. The information can be correlated to show

all materials that go into a product--and the conditions

during all of the process steps the materials underwent.

Many of these systems are tamper-proof to help companies

meet regulatory requirements, so there’s little room

to question the data. An MES is a rich source of detailed

yet contextualized information that allows Six Sigma programs

to take root and flourish.

Research findings from a newly released report, “MES

Performance Advantage: Best of the Best Plants Use MES,”

illustrate the benefits of MESs to plants undertaking Six

Sigma programs. Written by Industry Directions and sponsored

by Rockwell Automation, the report uses an existing database

of survey responses to questions about performance and business

practices and compares companies that are and are not using

an MES.

In a database of 106 plants judged to be the highest-performing

in North America during a period of five years, 24 responded

that they use Six Sigma methods extensively. Within that

group, 58 percent of respondents with Six Sigma initiatives

also use an MES. Despite the relatively small number of

Six Sigma users, the differences within the group are striking.

(All percentages listed here are the mean response of the

group mentioned--those using Six Sigma and either using

or not using an MES.) Here are some results:

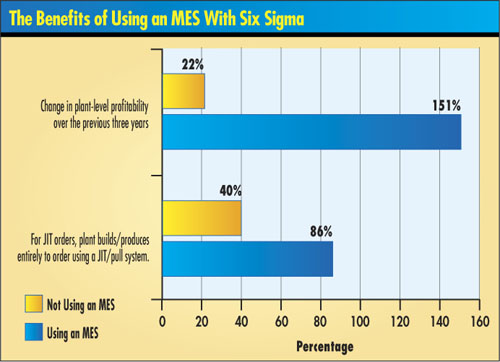

Companies using an MES together with Six Sigma improved

their profitability 151 percent over three years, whereas

those using Six Sigma without an MES improved profitability

by 22 percent, as illustrated on this page. Improving profitability

by even 20 percent is impressive, but organizations with

an MES improved 678 percent more, on average. Some of this

profitability came from improved productivity for plants

using an MES and some came from cost savings.

Companies using an MES together with Six Sigma improved

their profitability 151 percent over three years, whereas

those using Six Sigma without an MES improved profitability

by 22 percent, as illustrated on this page. Improving profitability

by even 20 percent is impressive, but organizations with

an MES improved 678 percent more, on average. Some of this

profitability came from improved productivity for plants

using an MES and some came from cost savings.

Process capability is a cornerstone of Six Sigma strategy.

The goal is to create business processes that generate 3.4

defects per million or fewer (Six Sigma including a 1.5

sigma drift). Again, the MES fostered much greater success

for the group of companies undertaking Six Sigma in this

study. Companies using an MES together with Six Sigma had

a process capability (Cpk) of 2.4, compared to 1.5 for those

not using an MES to support their Six Sigma initiatives.

Process capability is a cornerstone of Six Sigma strategy.

The goal is to create business processes that generate 3.4

defects per million or fewer (Six Sigma including a 1.5

sigma drift). Again, the MES fostered much greater success

for the group of companies undertaking Six Sigma in this

study. Companies using an MES together with Six Sigma had

a process capability (Cpk) of 2.4, compared to 1.5 for those

not using an MES to support their Six Sigma initiatives.

Some specific process results were greater cycle-time reductions

over three years--more than 54 percent greater in order-to-ship

cycle time, the primary target for customer satisfaction.

And, among plants using an MES with Six Sigma, the manufacturing

cycle time component shrank by more than 82 percent compared

to plants using Six Sigma alone (60.6% vs. 33.2% over three

years). In a previous study by Industry Directions, “Becoming

Demand Driven,” the key indicator of demand-driven

performance was revealed to be achieving cycle times shorter

than the customer order lead time.

Some specific process results were greater cycle-time reductions

over three years--more than 54 percent greater in order-to-ship

cycle time, the primary target for customer satisfaction.

And, among plants using an MES with Six Sigma, the manufacturing

cycle time component shrank by more than 82 percent compared

to plants using Six Sigma alone (60.6% vs. 33.2% over three

years). In a previous study by Industry Directions, “Becoming

Demand Driven,” the key indicator of demand-driven

performance was revealed to be achieving cycle times shorter

than the customer order lead time.

Companies using an MES with Six Sigma also decreased lot

sizes more dramatically and were better able to build to

order. For just-in-time orders, the plants using an MES

built entirely to order 85 percent of the time; those using

Six Sigma without the MES data source built-to-order for

JIT 40 percent of the time, as illustrated in the chart.

Customers who ordered on a JIT basis and got exactly what

they wanted built for each specific order were likely to

be more satisfied.

Companies using an MES with Six Sigma also decreased lot

sizes more dramatically and were better able to build to

order. For just-in-time orders, the plants using an MES

built entirely to order 85 percent of the time; those using

Six Sigma without the MES data source built-to-order for

JIT 40 percent of the time, as illustrated in the chart.

Customers who ordered on a JIT basis and got exactly what

they wanted built for each specific order were likely to

be more satisfied.

The study reports other benefits of MESs, both to companies

with Six Sigma programs and overall. What is clear from

this data subset is that having accurate, reliable and comprehensive

operational data from an MES helps companies fully leverage

Six Sigma initiatives. Those using MESs realize significantly

more dramatic gains in performance.

The five critical processes used in a Six Sigma program

are define, measure, analyze, improve and control. An MES

provides a foundation of data and ongoing support for all

of those except define--which it assists.

Define--Identifies business issues that affect

the customer, defines project goals and boundaries, and

distinguishes issues that must be addressed for improvement.

Here, existing MESs can be used to help identify problems

that must be addressed, whether in the process, materials

or output.

Define--Identifies business issues that affect

the customer, defines project goals and boundaries, and

distinguishes issues that must be addressed for improvement.

Here, existing MESs can be used to help identify problems

that must be addressed, whether in the process, materials

or output.

Measure--Gathers information about the current

situation as baseline process performance data and identifies

problem areas. MESs provide data about plantwide process

performance, usually with both current and historical data

available.

Measure--Gathers information about the current

situation as baseline process performance data and identifies

problem areas. MESs provide data about plantwide process

performance, usually with both current and historical data

available.

Analyze--Identifies root causes of problems and

confirms those causes with data-analysis tools. Again, an

MES has the foundational data, including all production

processes correlated to each other and the materials that

flowed through the manufacturing process, the personnel

that worked on them, the conditions in the plant and the

customer order that was filled. An MES can also feed its

data into analytical tools, and some MESs now have internal

operational analysis capabilities in the off-the-shelf software

product or can be built-in during integration.

Analyze--Identifies root causes of problems and

confirms those causes with data-analysis tools. Again, an

MES has the foundational data, including all production

processes correlated to each other and the materials that

flowed through the manufacturing process, the personnel

that worked on them, the conditions in the plant and the

customer order that was filled. An MES can also feed its

data into analytical tools, and some MESs now have internal

operational analysis capabilities in the off-the-shelf software

product or can be built-in during integration.

Improve--Implements solutions or changes to the

business processes to address the root causes identified

during analysis. The MES can be reconfigured to change process

parameters or flows, indicate conditions outside control

limits and provide operators with the necessary data to

avoid or correct problems early.

Improve--Implements solutions or changes to the

business processes to address the root causes identified

during analysis. The MES can be reconfigured to change process

parameters or flows, indicate conditions outside control

limits and provide operators with the necessary data to

avoid or correct problems early.

Control--Ensures day-to-day business processes

stay in the improved state and become standard and integrated

into the daily routine. The MES can enforce business processes--disallowing

operations when certain conditions are not met, for example.

It also measures performance on an ongoing basis to evaluate

the success of an improvement.

Control--Ensures day-to-day business processes

stay in the improved state and become standard and integrated

into the daily routine. The MES can enforce business processes--disallowing

operations when certain conditions are not met, for example.

It also measures performance on an ongoing basis to evaluate

the success of an improvement.

The July 2003 issue of Quality Digest featured an article,

“Six Sigma for the Rest of Us,” which discussed

ways smaller companies can succeed using Six Sigma without

making major investments in Black Belt training or major

process redesign. In keeping with this philosophy, MES technology

is becoming more available to companies of all sizes. A

variety of MES solutions are available today to meet the

unique requirements of companies large and small. Both MES

and Six Sigma solutions can be focused on a specific piece

of equipment or plant area, or they can provide a comprehensive

solution that manages the operation of an entire production

plant.

MES applications utilized in itemized situations are modular

solutions designed to collect and provide visibility into

equipment operating data. An MES solution provides information

needed by Six Sigma Black Belts to measure current performance,

analyze operations and identify opportunities for improvement.

MES applications can also provide feedback to operators,

enabling them to ensure that equipment or a line is operated

within defined control conditions.

The advantage of such modular solutions is that they’re

focused on requirements of a specific production area or

process. They’re configurable and have been designed

to meet the requirements of a specific area of the manufacturing

plant. The plant does not need to change its operations

to fit the MES. Rather, the MES can be configured to meet

the needs of the plant.

MES applications now being deployed are also scaleable.

In many cases, a Six Sigma project will be focused on a

single piece of equipment or line. At the completion of

the project, if value is demonstrated, the manufacturing

company will want to deploy the MES throughout its operating

plant. The current generation of MES applications has the

capability to be rapidly scaled-up from a single line to

an entire plant.

Many companies are deploying MES applications that enable

the collection and analysis of multiple types of data. Data

on machine downtime are no longer the sole information needed

to improve the throughput of a production line. New MES

applications allow Six Sigma teams to look at more complex

relationships and analyze downtime data, quality data, operating

conditions, product type and labor resources. In the past,

this required Six Sigma teams to generate separate reports

and then compare data across reports. Current MES applications

allow Six Sigma teams to view data in a single application

for review and analysis. This has been facilitated by the

capability of MESs to exchange data among various enterprise

systems (e.g., enterprise resource planning, material requirements

planning and laboratory information management system) and

their improved analytical capabilities.

In their book, Six Sigma: The Breakthrough Management

Strategy Revolutionizing the World’s Top Corporations

(Currency, 1998), Mikel Harry and Richard Schroeder discuss

the fact that companies improving 1 sigma each year, from

3 sigma to 4.8 sigma, will experience a 20 percent margin

improvement. Recent research shows that adding an MES to

support the Six Sigma program can further boost margin improvement.

At 151 percent over three years, the companies in Rockwell’s

newest study average about 50 percent margin improvement

each year. The reason for this success is twofold. First,

the Six Sigma process is enhanced when its analysis can

be based on critical production data present in an MES.

This data enables Six Sigma teams to make their analysis

and develop production improvement recommendations based

on solid and consistent data. Second, an MES also provides

data necessary to define current operations and establish

a baseline to measure improvement and value delivered to

the company.

Manufactures need to keep in mind that analysis of the

existing situation and recommendations for improvement are

just part of the Six Sigma process. MESs help provide the

capability to monitor the production process and implement

business process control to improve production execution.

Many Six Sigma projects and MES implementations have failed

in the past because MESs have not been utilized to help

drive the continuous improvement process. Manufacturers

must view MES technology as a vehicle for business change

and improvement in the manufacturing process.

By properly incorporating an MES with Six Sigma initiatives,

manufacturers can effectively boost profitability, productivity

and process across their operations.

Charles Rastle is an industry strategic marketing

manager for Rockwell Automation’s Global Manufacturing

Solutions group. Rastle earned his bachelor’s and

master’s degrees from the Colorado School of Mines,

and he earned his MBA from the University of Colorado.

Julie Fraser is a principal and analyst with Industry

Directions, a manufacturing and supply-chain analysis and

consulting firm.

|