| by Steven A. Mango

For more than a century, industrial manufacturers have used film applications for radiographic inspection techniques. Digital technology adds speed and convenience to many processes, and radiographers are seeking more efficient methods of accomplishing the inspection cycle through computer and digital methods, a transition that's changing the face of X-ray image processing.

There are four primary radiographic technologies (RT) used in aerospace: film, computed radiography (CR), digital detector array (DDA) radiography and fluoroscopy. The choice of which to use depends primarily on the type and manufacture of the component being tested, as well as on its size and engineering requirements.

Film radiography has a long history and is still considered an excellent technology. Film delivers high-quality spatial resolution, which allows for high sensitivity. Because of this, film radiography is often used on castings or forged metal parts--e.g., air foils, pumps, pump housings, gears, struts or landing gear components--where its sensitivity and high image resolution are particularly appropriate for identifying fine cracks or flaws that could lead to failure. Conversely, film inspection requires photographic development--a potentially problematic, time-consuming process involving chemicals harmful to inspectors and the environment.

CR, in which a phosphor plate is substituted for the sheet of film, is potentially applicable in the same cases as film and offers quicker results without chemical processing. Images on the phosphor plates are read and stored digitally for later review and archiving. This represents a huge advantage in decreased facility requirements because aerospace manufacturers must keep permanent records. For mobile inspection operations, some phosphor-plate readers can be situated conveniently in a van or truck, facilitating on-site image examination, reducing transport-capacity needs and potentially avoiding return trips. Because phosphor plates typically are more sensitive and have greater dynamic range than film, CR also reduces the exposure time needed to generate an image--a benefit to the useful life of the X-ray source. Despite the excellent sensitivity, however, current plate technology has some resolution limitations, which is the primary reason that film remains the preferred medium for critical, high-resolution imaging.

DDA radiography is a filmless, plateless alternative to analog X-ray imaging. The radiographic image is detected directly by amorphous silicon and selenium detectors and goes straight to a digital image file that can be viewed on a diagnostic display. DDA radiography is similar to CR in that it offers shorter exposure times, a large dynamic range and imaging without wet-film processing. Although DDA isn't as mobile as film or CR, the instant access to images is an attractive feature for some applications.

The one common element of CR, DDA and film radiography is that the images are static--i.e., snapshots of a limited space at one instant in time, which precludes observation of rapid changes, the movement of fluids or other potentially useful phenomena. Fluoroscopy, on the other hand, does allow real-time, continuous observation of an object. A fluoroscope consists of an X-ray source and fluorescent screen. The X-ray image on the screen is viewed via an image intensifier and CCD video camera. This eliminates the start-stop delays of shooting film images, mosaic-style, of very large objects--not to mention the costs and environmental issues associated with film and chemicals. Fluoroscopy therefore remains a cost-efficient technique for large, long structures, such as helicopter main blades, but it lacks the sensitivity to uncover extremely fine detail in more dense materials. Hence, it's seldom used to inspect critical metallic aircraft components.

Water is entrapped in the honeycomb core of a paddle (a part of a tail rotor blade) and will need to be removed.

This elliptical plug, which attaches the tail blade to the rear of the helicopter, is free and clear of defects.

|

Sikorsky Aircraft, the Connecticut-based manufacturer of helicopters for commercial, industrial and military markets, applies fluoroscopic and CR techniques to inspecting helicopter components at its overhaul and repair facilities in Shelton, Bridgeport and Stratford. Though film remains the standard when testing critical components for fine cracks and flaws, Sikorsky asserts that fluoroscopic and CR methods have the ability to meet sensitivity needs when inspecting a majority of aircraft structures and components.

Sikorsky applies radiographic procedures to key components during the manufacturing process as well as in periodic inspection and refurbishing, taking approximately 3,600 radiographic images a year. The inspection process is critical to Sikorsky because overlooked defects could have disastrous results, including mishaps costing millions of dollars in damaged equipment or, worse yet, a catastrophic loss of life.

"When testing new rotor blades, for example, we're mainly looking for water--which is seemingly harmless enough in small quantities but can cause significant damage if trapped inside during the manufacturing process," says Pete Laoretti, a quality assurance manager at Sikorsky. "Everything we inspect is airworthy before it leaves the shop, or it doesn't make it out the door."

Laoretti says that CR has helped speed up the inspection process, increase throughput by approximately 33 percent and conserve time when capturing, viewing and sharing inspection images on parts as large as Sikorsky tail rotors.

"Our ability to catalog and store images digitally is doubly useful. It means we don't have to stop the inspection process every time we image a flaw; we can just provide an engineer with the image, and he can locate the part to inspect it at his convenience," says Laoretti. "Then, we still have the original image to compare with an image taken after repair, to be sure all of the flagged locations are airworthy."

The larger main blades are inspected in real time using fluoroscopy, which allows the blades to be turned and shifted as needed to enable a good view of the blade's interior. "It would be nice to have blade images in an archive, too," adds Laoretti, "but it would take inordinate amounts of time to shoot enough images for a thorough inspection of an object that large."

Film applications aren't used as frequently by Sikorsky as other techniques but do come in handy when inspecting welds, castings, forgings, composite materials, powdered metals and electronics. "For example, we test electronic components with film to verify certain connections in automated systems," says Laoretti. "Film's ability to meet sensitivity requirements is the main reason it remains useful in our field. Aerospace radiographers work with materials every day that have characteristics only film can capture, such as delicate metals with long, fine grains."

On the down side, film processing requires lengthy exposure times, which holds up the production process. "It takes about 8 minutes to develop a film exposure," notes Laoretti. "That's approximately four times slower than the time it takes to produce and view a CR image--a process we can complete in less than two minutes."

Gary Larson, a radiographer with Buffalo, New York-based Quality Inspection Services Inc., worked with Sikorsky on its fluoroscopic and CR techniques as the company adopted CR during the past year. Sikorsky's shop uses oversize phosphor plates, reading the images on Kodak's ACR 2000 reader and viewing station.

"This system is robust enough to handle a 60-inch phosphor plate, which can capture tail rotors in a single exposure," says Larson. "When choosing a CR system, look for a product that offers ease of use, good sensitivity, easy storage capabilities and a low exposure time."

The emergence of fast computer systems, solid-state detectors and refined image processing software makes DDA radiography smart and practical to the aerospace radiographer. DDA produces an image comparable to a traditional X-ray. "A digital radiographic image is electronically transferred to the computer display without using a scanner like we use in CR or in film technology," says Larson. "It's similar to a real-time radiographic image but has a much higher contrast resolution."

CR is attractive for film applications in part because the investment in equipment is more modest than for DDA systems. CR also offers some advantages in mobility. But is that intermediate step of a latent image on a plate really necessary? Will DDA eventually dominate as technology continues to improve, and will radiographers become more comfortable with it?

"DDA radiography is potentially useful for small parts but wouldn't be practical for inspecting large objects such as the main helicopter blades," says Larson. "It's still hard to improve on CR and film radiography when selective imaging, increased sensitivity or permanent records are essential."

So, again, it depends on the applications. CR's growth may lie in applications where fluoroscopy is currently the preferred method--think of CR as fluoroscopy with better images and a permanent record when you want it. Meanwhile, keep passing those plates.

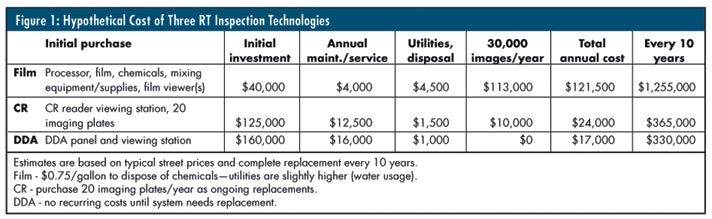

Comparing the cost of radiographic systems for nondestructive testing is a matter of apples and oranges--and bananas and sometimes the banana tree itself. Equipment cost and useful life vary substantially for the various options, as do costs for consumable goods.

Analog film users, of course, must keep buying consumables--film and chemicals. They also maintain film processors, which generally take up more floor space and require more elaborate facilities (e.g., plumbing, ventilation, and chemical collection, treatment and/or disposal) than the facilities and associated necessities for computed radiography. Film use also creates environmental and regulatory issues related to effluent discharge, along with inspections and the risk of fines.

The transition to digital technology requires an initial investment for a CR reader, which likely will cost more than a film processor. On the other hand, processors don't last as long as readers, and they require periodic replacement. Converting to CR doesn't always eliminate the need for film images, which are digitized after processing, meaning you may end up supporting (and paying for) two systems.

The greatest cost savings potential, by far, is in the elimination of film and chemicals when a lab goes completely digital. Again, buyers face a trade-off: A single CR imaging plate can cost a hundred times more than a sheet of film. The good news is that the storage phosphor plate can be erased after each use, allowing thousands of repeat exposures.

The lifetime of a storage phosphor plate varies as a function of environment, cleanliness and handling. With proper care, an imaging plate's lifetime will extend to thousands of cycles. Conversely, imaging plates will sustain damage during the normal use cycle, and we must consider them consumables--but only after they pay for themselves many times over in cost savings. DDAs used in direct digital radiography are even more expensive, but they may also last longer than phosphor plates.

From a cost-savings perspective, the case for transitioning to digital is obvious. The calculation is fairly simple: Determine the current and future film volume and associated costs, and compare those with the expense of a digital system.

A couple of pitfalls loom, however. In today's changing business environment, forecasting future production volume is challenging. One high-volume film user underestimated an impending decline in production. After calculating a reasonably favorable return on investment (ROI) and taking the plunge to digital, his business declined. Years later, he's still waiting for his ROI.

Another user reported that he was reluctant to make the full transition, so his company retained its film radiography capability. Without completely eliminating the expense for operating the processors and purchasing film and chemical consumables, the savings realized by the company weren't quite enough to pay for the transition to digital. Thus, its digital operation became an incremental expense rather than a savings.

The price of DDA systems with flat-panel detectors has come down recently, so DDA is becoming increasingly popular and may progressively replace CR. An entry-level DDA system might cost about $80,000, which typically includes a monitor and software; some high-end systems can cost as much as $150,000. DDA technology also requires selenium and silicon detector panels, another $60,000 each.

In comparison, a CR system typically ranges between $112,000 and $125,000. Scanner technology is purchased separately and costs about $48,000. Typical imaging plates cost several hundred dollars apiece. CR plates are capable of thousands of exposures if handled properly but will most likely require replacement after two to three years of use. Therefore, cost differences between CR and DDA systems are marginal and depend on brand and model type.

Film expenses are a different story. Film users, of course, must keep buying consumables--e.g., film and chemicals, which if eliminated can save buyers a tremendous amount. Film users also must maintain film processors, which generally take up floor space and require elaborate facilities.

When comparing film and CR applications, it helps to know that CR systems will take about 18 to 24 months to pay off, depending on the amount of film a user typically consumes in a year. CR scanners cost more than film processors, but the latter must be replaced periodically, whereas CR scanners last several years. The same applies when buying phosphor plates: A single imaging plate can cost a hundred times more than a sheet of film. But because CR plates can be erased after each use, they end up paying for themselves many times over. Thus, from a cost-savings perspective, going digital is a smart and worthwhile investment.

"It will take a few more years for aerospace markets to completely transition to digital, and that's essentially a good thing for us," says Larson. "But as an industrial radiographer who's been around the block a few times, it's safe to say film is still king when inspecting certain materials critical to building safe and reliable aircraft."

A Kodak employee for more than 30 years, Steven A. Mango joined the company's nondestructive testing group in 2002. He currently serves as worldwide technical manager, overseeing all regional activities dealing with Kodak's nondestructive testing products. Mango also manages the latest technologies in computed radiography at Kodak's state-of-the-art demonstration lab located in Rochester, New York.

Mango has written, presented and published several papers on various aspects of computer radiography and is an active member of American Society of Nondestructive Testing and ASTM International. He's a graduate of Rochester Institute of Technology and earned his bachelor's degree in image science. |