| by Phil Heil and Richard Daigle

The economic axiom that what goes up must come down has

held true in recent years. Money has been tight in many

industries, but forecasters tell us that what’s been

down will start to rise in 2004. This is good news for

most businesses, but it’s great news for

the machine vision industry.

In addition to the economic upswing, another factor contributing

to what could be the best year ever for machine vision

systems are smart sensors, or “smart cameras.” They’ve

come into their own, offering far greater power for far

less money than was the case even two or three years ago.

As manufacturers prosper, they will invest more in quality

control, inspection and robotic assembly--all areas in

which smart cameras can make a significant difference,

providing 100-percent inspection and no-fail robotic guidance.

This may sound like an optimistic fantasy, depending

on your company’s situation, but it’s not.

The National Association of Manufacturers forecasts a 6

percent production boost that will generate some 250,000

jobs in 2004, partially offsetting heavy job losses suffered

in recent years. The Manufacturers Alliance/

MAPI reported its business index rose to 77 during the

last quarter of 2003, the highest level since the index

began in 1972. Short- and long-term futures for machine

vision are equally bright.

There was a time during the early 1990s when smart cameras

had a reputation, perhaps deservedly, as expensive high-tech

gadgetry that didn’t deliver in terms of performance.

Just five years ago, the average cost of a machine vision

smart camera system was out of many companies’ price

range. Today, an even more powerful

system can cost less than $2,000. During a recent training

luncheon at DVT Corp. in Atlanta, one student, commenting

on a machine vision system’s capabilities, said, “It’s

not a matter of knowing what application the camera can

handle but what application it can’t handle.”

A proven track record for smart camera machine vision

will also carry weight in the minds of decision makers,

especially for applications in which meeting strict government

standards--such as 21 CFR Part 11 or other quality control

measures--is critical.

Machine vision systems are used in a variety of applications,

including:

n Pharmaceutical packaging inspection. The machine vision

systems are typically 21 CFR Part 11-compliant.

Automotive light bulb inspection that meets Six Sigma

standards Automotive light bulb inspection that meets Six Sigma

standards

Inspection

of fill-levels of opaque bottles using smart cameras in

concert with X-ray technology Inspection

of fill-levels of opaque bottles using smart cameras in

concert with X-ray technology

Inspection

to ensure Teflon coating is properly applied to medical

inhalant canisters Inspection

to ensure Teflon coating is properly applied to medical

inhalant canisters

Although machine vision applications have proved increasingly

useful in recent years, the technology offers untapped

potential in the manufacturing industry worldwide. As assembly

line speeds have increased, human inspectors can’t

keep pace with a 100- percent inspection rate.

Simple sensors and other rudimentary machine vision tools

offer a basic level of inspection, but as applications

grow in sophistication, smart cameras are proving their

worth on the assembly line. Packaging, pharmaceuticals,

automotive, electronics and plastics are all growing markets

for machine vision smart camera systems. Lower integration

costs and better after-sale support give the technology

a distinct advantage over frame-grabber systems in many

applications.

A smart camera or “smart image sensor” is

much more than just a camera. It’s a digital camera,

small enough to fit in the palm of your hand but also packed

with the high-tech capabilities of an onboard computer

processor and a CCD that captures digital images at the

smallest unit: a pixel.

High-end smart cameras can measure down to a tenth of

a pixel with total reliability and even smaller with varying

degrees of reliability. Smart cameras can take precise

measurements, sort by miniscule color variations and object

shape, and perform optical character recognition, bar code

recognition and other tasks--all at speeds faster than

most assembly line inspection rates. Smart cameras can

handle speeds up to 2,000 parts per minute, depending on

the application.

Sales of smart image sensors for manufacturing applications

have grown from 30 to 50 percent annually since their introduction

more than a decade ago. Vision Systems International conducts

annual financial analysis reports that review productivity,

profitability and other standards for public machine vision

companies. Its 2002 report, which looked at 31 companies

that receive 5 percent or more of their revenue from machine

vision/imaging, indicates a slowdown of growth as compared

to 2001 numbers but, nonetheless, a 19 percent median gross

margin. Despite absorbing blows from the sluggish U.S.

economy, the future of smart cameras remains bright.

The technology’s versatility and ease of use continue

to drive its success in the marketplace. Sensors are used

throughout manufacturing to provide feedback for process

control and monitoring. The sensors can direct their information

to programmable logic controllers through a hard-wired

DC connection. In the simplest case, the sensor provides

a yes/no indication.

For example, a proximity sensor will detect if a part

is present or not. More advanced sensors can provide a

variable result. For example, a fill-level sensor can indicate

the fluid height inside a tank. Another common example

is a bar code reader that collects a code and outputs it

via serial to a controller.

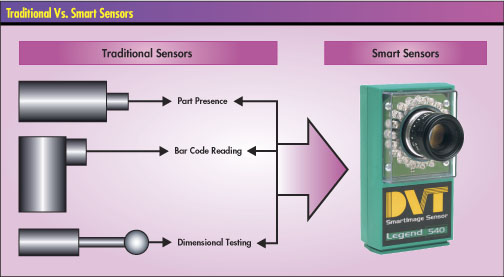

A smart camera is similar to standard sensors in that

it visually measures a quantity or reads information from

a part. The difference is that a smart sensor can be configured

to perform a variety of tasks simultaneously and communicate

this information in nearly any format, as illustrated on

page 21.

Smart cameras are used in a number of fields, including

automotive, pharmaceutical, plastics, electronics and food/beverage.

They’re proficient in detecting defects,

taking precision measurements, and picking, placing and

performing other positioning applications involving robots,

OCR, data collection and 2-D data matrix. Currently, packaging

is the fastest growing industry for smart camera machine

inspection.

For the first time, smart cameras are being used in an

X-ray unit that features affordable nondestructive testing

for nontransparent applications. The combination of smart

sensor technology and X-ray capabilities allows smart cameras

to perform varied functions on items that are hidden to

the naked eye.

The KMV Technologies InnerVision X-ray system, using

DVT cameras, is an example of the marriage between X-ray

vision and machine vision. The KMV unit can be used for

most nontransparent applications, including:

Checking wire connector integrity Checking wire connector integrity

Checking fill-levels in nontransparent containers Checking fill-levels in nontransparent containers

Checking proper fill of injection-molded parts Checking proper fill of injection-molded parts

Checking electrical connector pin alignment Checking electrical connector pin alignment

Unlike smart cameras, traditional sensors can’t

be programmed. Instead, they’re limited to performing

one task at a time, making a single pass/fail decision

based on adjustments to sensitivity. A typical application

might read the bar code on a part, perform a measurement

and relay this information to the factory network. The

PLC would set the part aside for rework if it didn’t

meet the specification, and the work cell controller would

track the part based on the bar code. With a traditional

sensor, this application would be done using contact probes

and a bar code scanner connected to a PC--three different

hardware units performing separate tasks with separate

information channels.

A smart camera can perform these tasks simultaneously

with the same set of tools, completing the application

at a lower cost and providing more options for flexible

manufacturing. It can also convey information from more

than one inspection in one communication channel.

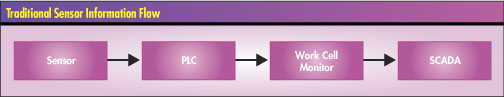

Two major classes of vision systems compete in the market

today. Vision and photoeye systems can be taught using

a single button or a video game controller, whereas smart

cameras are connected to a PC. The former class is easy

to set up but less flexible and limited in communications

options. Such sensors are best used for solving simple

problems when a great deal of automation hardware is already

present to handle variations and communications, as illustrated

at the top of page 22.

Traditional sensors using serial connections make pass/fail

decisions that can’t be integrated into one system

but must instead travel to different systems on different

paths. Because they’re not programmable, traditional

sensors can’t make intelligent decisions about information.

They simply make one decision based on input from one source.

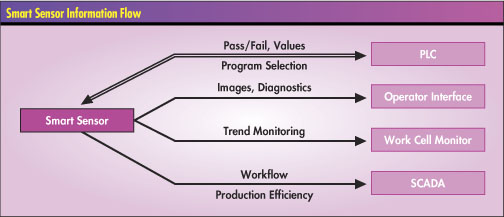

When a customer uses a PC and takes advantage of the familiar

Windows interface, setting up a more advanced class of

smart camera is easy. In this case, a powerful communications

system’s flexibility can be fully configured. When

standardizing on a common sensor platform, a single software

package can be learned, and many different applications

can be solved quickly with a common interface, as illustrated

on page 22.

Smart image cameras handle information flow much more

efficiently than traditional sensors. Smart cameras can

perform more than one inspection at a time, sending that

data in a single stream to PLCs or other devices. The data

can then be easily stored for analysis or use with reject

mechanisms or other components on the line. Smart cameras

are commonly found in the automotive industry, where there’s

an urgent need for quality, low cost and ease of use. And

now, with the expanded capabilities of recent models, packaging

and pharmaceutical industries also make use of the technology.

The applications vary widely, but some common problems

solved by smart cameras include checking for a part’s

presence or a defect’s absence. When first developed,

the smart camera was designed to replace arrays of photoeyes

that were used to verify that a part was assembled properly.

The photoeyes did a great job until it was time to switch

the line to a new part.

A smart camera can draw on hundreds of configuration

files to determine what inspection is to take place. As

tools were added to the design, tasks such as dimension

checking and tolerance verification were accomplished with

low-cost platforms. Formerly done by humans or analog frame

grabber-based vision systems, the smart camera proved that

direct-image acquisition provided a level of consistency

that hadn’t been seen in a hardware device costing

less than $10,000. This led to further improvements to

handle bar code reading and optical character recognition

in a single package. Applications that would normally be

done with four or five different devices could be solved

with one.

Throughout the 1990s, the Ethernet market outgrew its

humble beginnings of connecting PCs in schools and offices.

Industrial devices emerged that could communicate over

this now ubiquitous interface. In late 1998, DVT introduced

the first vision smart sensor with onboard Ethernet. The

smart sensor had outgrown its role as a simple yes/no decision

maker into an information provider for the entire factory.

In the coming years, as industrial quality standards

merge, the Ethernet may well be the hardware interface

that binds all the equipment. Smart

sensors will evolve along with the standards to support

communication, from the least expensive PLC to the most

costly enterprise resource planning software package. As

software and hardware are added, these sensors will be

able to handle increasingly complex visual inspection tasks.

At the same time, the falling costs of electronics and

the availability of free training will allow more of the

sensor market to be overtaken by inexpensive smart sensors.

The success of new technology is usually tied to the

ebb and flow of economic fortunes. When money flows, technology

grows. As the machine vision industry is fueled by new

capital expenditures, smart camera technology will continue

to provide more robust solutions for the manufacturing

world.

Phil Heil earned his mechanical engineering bachelor’s

degree at Carnegie Mellon University and his doctorate

in mechanical engineering at Georgia Tech. He has worked

at DVT Corp. in the Applied

Engineering Department since 1996. Heil has since worked

in training, technical support and application support

for DVT.

Richard Daigle has a bachelor’s degree in journalism

from Southeastern Louisiana University and a master’s

degree in communications from Georgia State University.

After serving as reporter and editor for a daily newspaper

in South Georgia, he worked in public relations for the

State of Georgia Department of Natural Resources, Coastal

Resources Division. Richard was formerly a writer for a

multimedia company in Atlanta. Since joining DVT, Daigle

has launched the company’s quarterly magazine, Vision

in Action.

Portions of this article © 2003, Society of

Manufacturing Engineers.

|