FDA Warns Boston Scientific, Guidant

Boston Scientific Corp., one the world's largest manufacturers of medical devices, has been cited by the Food and Drug Administration for several "serious" lapses in its quality assurance program. Boston Scientific Corp., one the world's largest manufacturers of medical devices, has been cited by the Food and Drug Administration for several "serious" lapses in its quality assurance program.

In a letter to the company, the agency reports regulatory problems at three of Boston Scientific's facilities. The letter also expresses concerns about the company's quality systems at six of its facilities, as well as recent recalls. However, it doesn't mention any specific product performance issues, although one of the problems cited in the FDA's letter is a concern that the company hasn't properly tracked complaints over certain products--including the Taxus coronary stent, a cardiovascular device that generates nearly half of Boston Scientific's revenues. The letter also advises the company that its corporatewide corrective action plan relating to three prior warning letters issued in May and August of last year is inadequate.

In reaction, the company established a global complaint information system that addresses some of the FDA's concerns. It has also launched a global initiative to further improve and harmonize its quality systems. An FDA inspection of the company's Galway, Ireland, plant, where the Taxus device is manufactured, concluded with no reported observations.

"Product quality and performance have always been a top priority at Boston Scientific," says Jim Tobin, the company's president and CEO. "We are bringing the same urgency to our overall quality and reporting management. We believe we have made a lot of progress, but we still have a ways to go."

Boston Scientific recently won a bidding war with Johnson & Johnson over the acquisition of Guidant Corp., the world's second-largest producer of heart rhythm devices, a company that has its own alleged quality assurance problems. Last June, Guidant recalled 109,000 faulty defibrillators that were linked to at least seven deaths. In a letter to the company dated December 22, 2005, the FDA reported that persistent quality problems at Guidant's St. Paul, Minnesota, manufacturing facility "may be symptomatic of serious underlying problems in manufacturing and quality assurance systems."

Among the issues cited by the FDA in its letter to Guidant are:

• Failure to adequately verify process-testing methods for hybrid assembly processes

• Failure to establish, maintain and document adequate procedures for when changes or process deviations occur

• Failure to establish and maintain adequate procedures to identify actions needed to correct and prevent the reoccurrence of nonconforming product and other quality problems

• Failure to analyze sources of quality data to identify existing and potential causes of nonconforming product

• Failure to adequately maintain device history records

Until the FDA can verify corrections to the facility's quality management practices, the FDA won't permit export or premarket approval of some of Guidant's defibrillators and pacemakers. Guidant reports that it has already completed 90 percent of the commitments it made to improve its quality management systems, and that it will be ready for another FDA inspection in mid-2006.

Guidant is fending off 60 lawsuits related to the June recall of its defibrillators. One of the suits was filed by Justin Machado, a former employee who claims that the quality problems stem from a decision to put manufacturing managers in charge of the quality and training office where Machado worked. Machado was fired in July.

Guidant didn't return calls asking for comment about Machado's claims.

In a letter to the FDA responding to the warning, Guidant reports that it has hired an external quality system consultant to help it fix its apparent quality problems, and assures that Guidant is fully committed to continuous improvement.

For more information, please visit www.guidant.com or www.bostonscientific.com.

Winning the Quality Game

Who doesn't like to play? Who doesn't like to play?

That's the approach some companies are taking to training. While no one can claim that the era of days-long training sessions in stuffy boardrooms is over, a new breed of training companies are creating games that teach employees the rules of quality in game form.

Take Paradigm Learning Inc., for example. The Tampa, Florida-based company has trained nearly one million people in 400 companies through its flagship board game, Zodiak: The Game of Business Finance and Strategy. The game puts teams of employees in charge of a $40 million business, and teaches quality and financial strategies. Teams play the game in four-hour blocks that are facilitated by a Paradigm employee who assumes a new game-related identity to make the event more interesting. Following the game, the facilitator demonstrates how the lessons learned in the game apply to the players' specific business.

The company takes an innovative approach to professional education: make it fun, make it applicable, and make it interesting--all while illustrating the specifics of the employees' company's goals and challenges.

"When you blend those components, you give employees the 'aha' moment that senior executives have every day, every week, every month, from seeing the company's whole picture," says Kurt Hine, Paradigm's director of marketing. "It addresses the intellectual side of learning as well as the human component that exists at any workplace."

Zodiak was originally designed for Harris Semiconductor of Melbourne, Florida. Since Paradigm Learning was founded in 1994, it has also developed several other games for dozens of companies, such as Safeway, one of North America's largest grocery chains; Schneider National, a national transportation and logistics company; and the United States Air Force.

Paradigm also offers customized discovery maps. These large tabletop illustrations show a company's current, desired and future states--all in full color and using the highest quality graphic design techniques. They're most often used to graphically illustrate often-complicated business transformations to employees.

Quality Productivity Bingo has also made training easier for employers and a lot more fun for employees. The game, developed by Dewayne Gest of The Gest Group, can be customized to fit just about any work environment. Companies can use the game to identify areas that need improvement and monitor improvement activities that are already underway.

Gest invented the game in 1992, several years after he played a quality-related bingo game at a plant where he worked as a quality engineer. He tweaked traditional bingo to include terms related to quality function deployment (QFD) and total quality management (TQM), and referenced quality experts such as Deming. Gest designed Quality Productivity Bingo so that it could be played by an indefinite number of players.

"It's just a good way to get people involved in improving any kind of organization, and they enjoy it because it's a game," Gest says. "But while they're playing, they're improving the company without even really knowing it."

For more information, please visit www.gestgroup.com or www.paradigmlearning.com.

Hazardous-Substance-Free Conference

An upcoming conference will offer attendees a unique environment to learn about the production of hazardous-substance-free (HSF) products.

HSPM2006 will include a thorough overview of QC 080000 IECQ HSPM, a recently released specification that addresses new requirements in countries all over the world (such as RoHS in Europe and Articles 11 and 12 in China) prohibiting hazardous substances in exported electronic products and components. Industry leaders, executives of multinational companies and representatives from companies of all sizes are expected to attend to hear about the implementation of HSF requirements.

Don Gray, chairman of the International Electrotechnical Commission Conformity Assessment Board, and Dave Smith, chairman of the International Electrotechnical Commission Quality Assessment System for Electronic Components, will be the keynote speakers. Additional presenters will speak on such topics as "Overcoming Resistance to Change on the Way to HSF," "The Impact of HSF on Distribution" and "Taking the Lead Out of Solder."

The conference will be held April 3-4 at the San Francisco Airport Marriott in Burlingame, California. An IECQ HSPM training course will be held April 5-7 at the same location. The Salot Bradley Group International is hosting the event.

For more information, please visit www.hspmsymposium.com.

Quality Expo, AIAG Announce Conferences

Reed Exhibitions (organizer of Quality Expo) and the Automotive Industry Action Group have announced plans to operate side-by-side conferences.

Quality Expo will be held June 7-8 at the new Rock Financial Showplace in Novi, Michigan. Quality Expo will include hands-on access to a comprehensive array of the latest inspection, test and measurement equipment, and software and services from more than 200 top suppliers. There will also be an expanded technical conference with workshops and sessions covering quality management systems, advanced quality tools, quality fundamentals and benchmark research.

Simultaneously with Quality Expo, AIAG will host its first-ever Best Practices Summit, which will feature three session tracks: product life cycle management, quality, and the Global Metrology Congress. The Global Metrology Congress will include a panel discussion with representatives from the National Institute of Standards and Technology, Ford Motor Co., DaimlerChrysler AG and General Motors Corp. AIAG Best Practices Summit attendees will have complimentary access to the Quality Expo exhibition hall and all special events.

"We are pleased to have this opportunity to team up with Quality Expo 2006," says J. Scot Sharland, AIAG executive director. "With its successful history of delivering educational and technical content to thousands of quality professionals, it was only natural to combine AIAG's expertise in automotive best practices and standards with the conference by presenting AIAG's Best Practices Summit. We intend to deliver the latest and most comprehensive information and tools to help companies achieve better product development, quality, reliability and metrology interoperability."

For more information, visit www.qualitydetroit.com. or www.aiag.org.

Minnesota Council for Quality Receives Grant

State Farm Insurance recently awarded the Minnesota Council for Quality a grant to support a quality assessment program in the state's K-12 schools.

The $16,500 grant will support the annual assessment of approximately one-third of Minnesota's school districts. The data from the assessments are used to help education leaders identify improvement opportunities. The grant money will also be used for Baldrige criteria training for teachers and administrators, and to implement improvement activities in schools.

"When educational organizations assess their performance against the Baldrige criteria, school leaders not only gain a better understanding of their strengths and opportunities but also can make systemic and focused improvements that build organizational capacity, improve efficiency and effectiveness, and, most important, improve student learning and other organizational outcomes," says Brian Lassiter, Minnesota Council for Quality president.

The overall goal of the program is to improve student learning and organizational performance in 12 districts in southeast Minnesota. There are three objectives: increase knowledge of the Baldrige framework among teachers and administrators in the area, facilitate Baldrige-based assessments in the districts and support improvement initiatives.

The program is a joint effort between the Minnesota Council for Quality and the Rochester Area Math and Science Partnership, which has focused on educational improvement in southeastern Minnesota since 1991.

For more information, visit www.councilforquality.org.

Dive In! Dive In!

Here's another item to cross off your worry list: The waters of the country of Malta are safe for bathing.

The information was reported in the State of the Environment Report 2005, which noted that the tiny Mediterranean country's bathing waters meet the European Union's Bathing Water Directive quality standard. The report was provided by the Malta Environment and Planning Authority.

Fresh-water bathing is a popular activity in Malta, which is a haven for tourists. The Maltese government monitors dozens of outdoor bathing facilities each week.

So, next time you're in Malta, remember to take a bath.

NQI Ceases Offering Auditor Certification NQI Ceases Offering Auditor Certification

Effective this month, Canada's National Quality Institute will no longer offer auditor certification.

The organization, which is Canada's leading nonprofit quality training and recognition organization, reports that it wants to focus its energies on personnel certification and administration of the annual Canada Awards for Excellence program. The CAE is similar to the Baldrige Awards in the United States. NQI and RABQSA announced last spring that they had formed a partnership to allow organizations registered to standards by NQI to also become registered to one or more of RABQSA's certification schemes. That arrangement is now over, reports Catherine Neville, NQI vice president for personnel certification.

"During this past year while working with RABQSA International, NQI has been reviewing its other programs," says Neville. "It has been concluded that to optimize our contribution to organizational excellence in Canada... it makes good sense to focus our personnel certification energies on the certification of excellence professionals. We would like to wish RABQSA International every success as they work to provide optimum and comprehensive certification services to auditors in Canada and worldwide."

She reports that the two organizations will maintain close ties, and will hand over any remaining certified management systems personnel to RABQSA.

For more information, visit www.rabqsa.com.

New QIO Standards

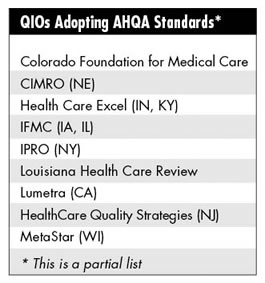

The American Health Quality Association recently released new standards for its member quality improvement organizations (QIO). The American Health Quality Association recently released new standards for its member quality improvement organizations (QIO).

The AHQA's board of directors approved the policy in December, and already more than a third of all QIO boards--in states home to more than half of the nation's Medicare beneficiaries--have agreed to comply. QIOs are consulting groups that help Medicare recipients and care providers receive and deliver appropriate health care services, and reduce medical errors. According to the AHQA, most QIOs already follow the new standards. However, the new policy formalizes the rules to encourage their increased adoption by the entirety of QIO belonging to the AHQA.

The standards address QIO board and executive compensation, board diversity and independence, travel expenses, and procedures to prevent and mitigate conflicts of interest.

"The only way QIOs can succeed is by earning and maintaining the trust and respect of patients, providers and public policymakers," says David Schulke, AHQA executive vice president. "Adoption of these standards by every QIO will show the public that QIOs are committed to fiscal integrity and accountability to a broad array of stakeholders. This is just the first step."

For more information, visit www.ahqa.org.

William M. Harral: 1942-2006 William M. Harral: 1942-2006

William M. Harral, a longtime Quality Digest contributor, died January 23 in Northville, Michigan. He was 63 years old.

During the course of 20 years, Harral held engineering, manufacturing, testing and quality management positions at Ford Motor Co. He founded Arch Associates in 1983 and held an MBA from the University of Michigan. Harral held multiple quality-related professional certifications and was named a Fellow of the American Society for Quality in 1992. He was an active board member of A2LA and served as that organization's second vice chair in 2005.

Harral was co-author of several books, including The ISO 9000 Handbook (editions one and two), The QFD Handbook, ASQ Advance Quality Planning, ASQ Greater Detroit Certified Quality Engineer Refresher Manual and ASQ Auditor Handbook. |