| by Dick Mierzejewski

Glossary of Air Gaging Terms

Amplifier--the readout

of an air gage system. An amplifier is a device containing

the necessary restrictions to change the pneumatic

pressure or flow. It displays readings on a scale

as dimensional values. When connected to air gage

tooling, readings are amplified many times, allowing

the user to easily read the size being measured.

Balance--the resultant

nonmovement on the display of an air amplifier that

occurs when one nozzle of a two-nozzle tool is closed

toward the workpiece and the other nozzle equally

compensates for that movement

Column--an air-electronic

amplifier or a flow system amplifier featuring a vertical

bar graph display or flowmeter tube

CTS--air tooling designed

to measure close-to-shoulder, such as an air plug

used to measure counterbores. Removal of front-center

post on air plugs below 2.510 in. becomes a blind-hole

design.

Flowmeter tube--a graduated

glass tube of a precise size with a “floating”

cork that displays the readings on a flow air gage

system. Different size tubes are necessary to accommodate

all air gaging applications.

Full scale value--the

numeric equivalent of the graduated display. FSV is

usually 1.5 to 2 times greater than the tolerance

being measured to show approach or oversize conditions.

Magnification--the visual

increase of size that is created by an air amplifier.

In systems in which the air amplifier has adjustable

magnification, this is accomplished by adjusting the

flow or back-pressure within the amplifier to agree

with the master sizes. On systems that have an air

amplifier with fixed magnification, it’s essential

that the air gage tooling is precise for full amplification

to be achieved.

Nozzle--the orifice in

the air gage tooling that emits the air that blows

against the part being measured. The diameter size

of the nozzle is dictated by the air gage system used.

The quantity and location of nozzles are determined

by the measurement application.

Nozzle drop--the engineered

distance that a nozzle is recessed below the surface

of the air gage tool. Nozzle drop is governed by the

air gage system. A deeper nozzle drop can provide

longer wear life of the air gage tool.

Resolution--the smallest

increment on the full-scale display of the amplifier

Restriction--a device

used to control air pressure or flow within an air

gage amplifier. This may be done with a fixed orifice

of a precise size, with adjustable needle valves or

with both.

Zero--the process of

positioning the magnified spread on an amplifier to

a desired relative position on the scale. Zero is

generally at midpoint of the full scale, but the spread

may be positioned anywhere.

Zero size--the desired

midpoint or nominal size of the feature being measured

as it relates to the scale. On back-pressure systems,

zero is usually the midpoint between the minimum and

maximum allowable size. On the flow system, zero is

generally the minimum size.

|

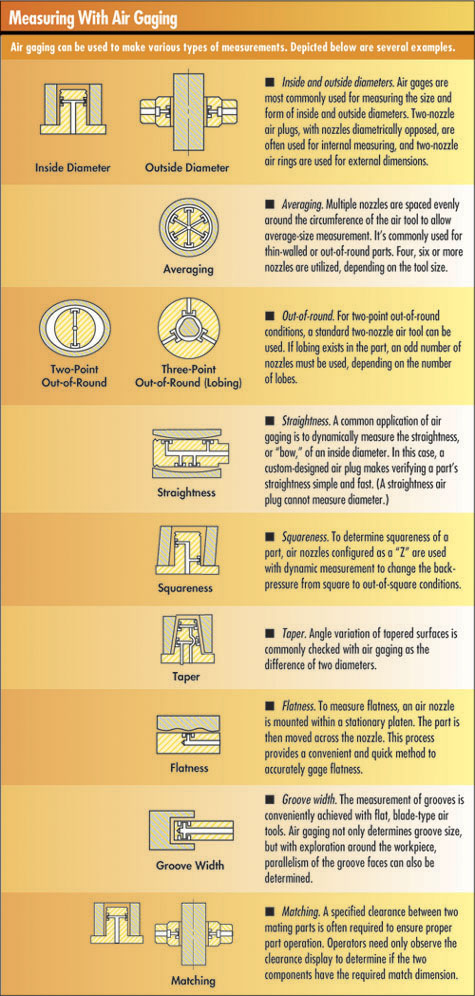

In the competitive world of

manufacturing, many companies are looking to increase quality

and productivity while reducing frivolous expenses. Some

have set their sights on noncontact measurement as a means

of saving valuable resources. One such type of measurement

is air gaging, a method of precise comparative dimensional

measurement that offers users the advantages of improved

workflow, increased productivity and decreased downtime.

As this article explains, air gaging is ideal for measuring

dimensions with tolerances smaller than 0.005 in. When gaging

tight tolerances, resolutions as small as 0.000002 in. can

be achieved. Its noncontact characteristic makes air gaging

particularly useful for checking soft, highly polished,

thin-walled or other delicate materials.

Chief among the benefits of air gaging is its ease-of-use,

which helps produce accurate results even when performed

by unskilled employees. Operation is as simple as presenting

a tool to a workpiece and observing the reading. Speed is

another benefit: A row of multiple-column amplifiers can

be scanned in one glance, reducing time and fatigue. Moreover,

relationships (e.g., squareness) that cannot be checked

by fixed-limit gaging--and are costly to do by other means--are

easily measured with air gaging.

Air gaging is also economical. Once the basic system is

purchased, relatively inexpensive additional tooling can

be used for a wide variety of applications. Air gages effectively

measure all common types of dimensions and are particularly

suited for measuring dimensional relationships and match

gaging.

Most air gaging systems operate at air pressures that

can purge workpieces of contaminants (e.g., abrasive particles,

coolant, etc.) at the measurement point, eliminating the

need for separate cleaning in most operations. And, because

air gage tooling has no moving parts, it’s virtually

immune to fouling. Air gaging offers a wide choice of tooling

for single or multiple measurement applications, and when

repair is needed, air tools are simple to fix.

A brief examination of the fundamentals of air gaging

will illustrate the basic premise of air gaging and its

evolution into today’s manufacturing environment.

To achieve its precise dimensional measurement, air gaging

relies on a law of physics that states flow and pressure

are directly proportionate to clearance and react inversely

to each other.

The regulated air flows through the restriction (e.g.,

a needle valve or jeweled orifice) and then through the

nozzle. When the nozzle is open to the atmosphere, there

is maximum flow through it with minimal pressure--called

“back pressure”--between the restriction and

the nozzle.

As an obstruction is brought closer to the front of the

nozzle, air flow from the nozzle diminishes, and back-pressure

builds. When the nozzle is completely obstructed, air flow

is zero and back-pressure reaches the pressure of the regulated

air supply. During this example, air flow moves from maximum

to minimum, whereas back-pressure moves in the opposite

direction: minimum to maximum.

These values can each be plotted against the nozzle’s

clearance from the obstruction. Except for the extremes

of both back-pressure and flow, the curves are straight

lines, representing the linear proportions that establish

the basis for all air gaging.

Thus, measured decreases in flow provide an accurate correlation

between the distance of the nozzles in the air gage tool

and the obstruction (i.e., the surface of the workpiece

being measured). Similarly, increases in back-pressure indicate

less distance between the tooling nozzles and the workpiece.

Although the concept of air gaging may be new to some,

the technique itself has been around for decades.

Air gaging is a proven technology that has been refined

for more than half a century. The first back-pressure air

gages were developed in France before World War II by a

carburetor manufacturer seeking a method of gaging its carburetor

jets.

The company relied on one of the simplest air regulators

ever developed. The first restriction suitably reduced the

air pressure, and an open-ended tube from a “T”

in the air line was submerged in water. Any air contributing

to pressure in excess of the pressure at the depth of water

bubbled out the bottom of the tube.

The water column also rose in the indicator tube fed from

its bottom, and a second restriction before the “T”

in the air line between the top of the indicator tube and

the air plug provided zeroing control. As back-pressure

affected the level of water in the tube, distance between

the air plug nozzles and the workpiece wall was indicated.

In 1943, a patent was issued for the simple system--the

basis of today’s back-pressure air gages. One of its

important features was the use of the newly developed pressure

regulator, which eliminated the evaporation problem of the

first system. Also noteworthy is its direct indication of

dimensional deviations by means of a dial readout. At about

the same time, another company developed a system for measuring

the flow variation rather than the back-pressure.

Improvements in air gaging systems continue to the present,

adding back-pressure bleed and back-pressure differential

systems to the roster of simple back-pressure and flow technologies.

This article examines all four contemporary systems, as

well as today’s enhancement of measurement precision,

flexibility, speed and usefulness through amplifier technology.

Air-electronic amplification and data collection/processing

have raised the resolution of air gaging to the level of

millionths of an inch while providing output of measurement

data for statistical process control.

Four general types of air gaging systems are in use today:

back-pressure bleed, back-pressure, differential and flow.

Each has definitive characteristics that affect its diversity

of application, accuracy, efficiency and ability to compensate

for degradations of associated tooling.

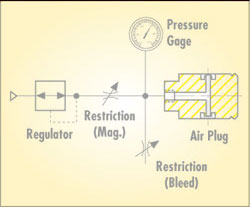

The “bleed” feature in this configuration

accomplishes the back-pressure bleed system’s greatest

benefit--its versatility. Tooling for different air gaging

systems may be used with the back-pressure bleed.

The back-pressure bleed system is configured with a fixed

regulator to control incoming air pressure for maximum linearity.

Key to this system’s uniqueness is the important addition

of a second adjustable restriction in the feed line opposite

the output leg. This second restriction allows users to

adjust for different air gage tooling, as illustrated below.

Back-Pressure Bleed System

The system’s magnification is controlled by the

typical adjustable restriction between the regulator and

air tool. The second adjustable restriction releases excess

air into the atmosphere to adjust the zero position. Two

setting masters--minimum and maximum--are used to calibrate

the system, defining and displaying both ends of the tolerance

range for accurate reading of workpiece deviation.

Single-master systems indicate only nominal conformance

at the zero point. The back-pressure bleed system defines

the tolerance range and explicitly indicates the location

of any workpiece in that range. No bad part ever passes.

These systems can also compensate for gradual tool wear

or variations in tooling sensitivity and allow the use of

different nozzle sizes without losing full amplification.

Back-pressure bleed systems operate at generally higher

air pressures than other systems, permitting greater nozzle

drop. Nozzles are more protected against wear and damage

that can affect measurement accuracy. The higher air pressure

also offers better self-cleaning properties.

This system is capable of the broadest magnification adjustment.

It accommodates almost any size nozzle, as large as 0.093

in. or as small as 0.020 in. This is especially beneficial

when small nozzles are required to check narrow lands.

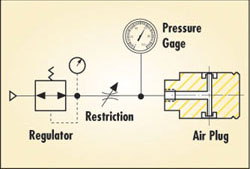

Remove the second adjustable restriction from the back-pressure

bleed system, and you get a back-pressure system. This two-master

system operates just as the back-pressure bleed without

the tooling versatility. The back-pressure system requires

dedicated tooling and amplifiers with limited ranges.

Back-Pressure System

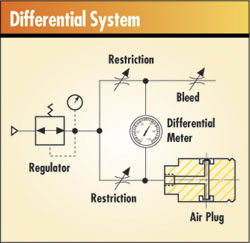

In a differential system, sometimes referred to as a “balanced”

system, the air stream is divided and flows through two

fixed restrictions, as illustrated below. One side of the

system, the bleed leg, ends in a zero valve that balances

pressure to the fixed second leg of the system, terminating

at the air plug. The difference between these two legs is

measured by means of the differential pressure meter, which

bridges the two legs.

The differential system is set to zero using a single

master for each tooling configuration, making setup somewhat

faster. However, the differential system amplifier can only

be set to zero. Damaged or worn tooling could result in

inaccurate readings. Additionally, with a single-master

system, the entire amplifier must be calibrated--rather

than just the masters, as in two-master systems.

Tooling for the back-pressure differential system must

be ordered for each magnification. Because the single-master

system has fixed magnification, worn, damaged or fouled

tooling must be returned to the manufacturer for service.

Another drawback of this system is that each amplifier only

accommodates one full-scale value. If an application requires

the measurement of different tolerances, several amplifiers

may be necessary.

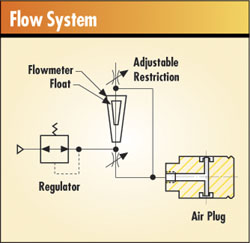

The air flow method is measured and read in a flowmeter

tube that supports a float. It’s a two-master system

with magnification and zero position set by two adjustable

restrictions, as illustrated on page 35. As such, the flow

system provides accuracy in reporting workpiece deviations

within tolerance, similar to the back-pressure bleed system.

The range of magnification is augmented by changing flow

tubes and scales rather than by a simple adjustment.

Flow gages, by their nature, require a greater volume

of air to generate movement of the float. This requires

tooling with larger nozzles, which must be kept closer to

the part by designing them with a shallower nozzle drop.

Shallow nozzle drops can shorten tool life. Also, when measuring

smaller workpieces necessitates smaller air plugs and smaller

nozzles, it’s difficult to get full amplification.

To its credit, the flow system can be used with long hoses

without affecting the response time of the amplifier. This

feature makes the flow system ideal for checking long holes,

such as gun barrels or oil drill bushings.

The variety of air gaging methods offer users both the

benefits of noncontact measurement and a number of choices

depending on the specific applications. Each option’s

ease-of-use will come in handy during high-yield production

schedules, and their accuracy won’t compromise your

organization’s quality efforts. When seeking a noncontact

means of metrology, air gaging could be the answer to your

quality measurement questions.

Dick Mierzejewski is manager of sales engineering

at Edmunds Gages. He has more than 30 years of engineering

experience in the field of metrology, specializing in air

and electronic gaging, automation and custom vision systems.

He can be contacted at rmierz@edmundsgages.com.

|