Managers Disagree on Quality’s

Definition

A survey sponsored by the American

Society for Quality reveals that the majority of U.S. executives

believe quality contributes to the bottom line, but the

way they define quality varies.

More than 600 executives from four industry segments--manufacturing,

services (including government), health care and education--provided

their perspectives on the value that quality brings to their

organizations. Of those asked, 99 percent said they believe

quality contributes to the bottom line, and 92 percent believe

that an organizationwide effort to use quality techniques

provides a positive return.

However, defining quality didn’t elicit such a uniform

agreement. Sixty-four percent of respondents believe that

quality is a management tool, and 36 percent believe quality

is built into a product or service but isn’t necessarily

a management tool. When asked to define quality, the majority

of respondents equated quality to customer satisfaction.

“It’s encouraging to know that most executives,

no matter in what industry, believe in the practice of quality

and the value that it can bring to their business--not just

in terms of economic return but also in the form of customer

satisfaction,” notes ASQ President Ken Case. “However,

it’s a bit disconcerting that many executives don’t

view quality as a business management tool when many of

the continuous improvement efforts practiced in business

today grew out of the quality discipline and the work of

quality professionals.”

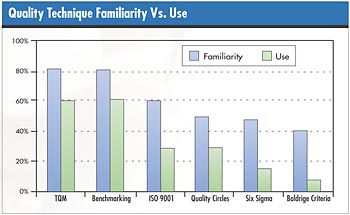

The survey also indicates that there’s a gap between

executives’ awareness of quality improvement processes

and implementation. When asked about their awareness and

usage of benchmarking, total quality management, quality

circles, ISO 9001, Six Sigma and the Baldrige Award criteria,

respondents from all four industry segments reported high

awareness and usage of TQM and benchmarking.

Manufacturing executives report greater awareness of ISO

9001, quality circles, Six Sigma and the Baldrige criteria

than leaders in the services, health care and education

sectors.

Actual use of all six techniques across all industries

was considerably lower than was reported awareness, as illustrated

below.

“The sizeable gap between usage and awareness leads

me to believe that businesses and organizations either don’t

use quality methodologies to improve their operations or

they just don’t realize that the processes they have

in place are attributable directly to the quality discipline,”

adds Case.

The survey was conducted by Market Probe, a global marketing

research company. A full report of the findings, including

industry-specific breakdowns of responses and demographics,

can be found at www.asq.org/survey.

The site redirects to a PowerPoint presentation.

ISO 9001 Users Go Online for Assistance

|

The ISO survey includes questions covering four topics:

Details about the nature and size of your organization

Details about the nature and size of your organization

Users’ experience with the ISO 9000 series,

both the 2000 version and previous versions

Users’ experience with the ISO 9000 series,

both the 2000 version and previous versions

Difficulties users may have encountered with ISO 9001:2000,

with the opportunity to explain the nature of the

difficulty and suggest alternative text to address

the problems, along with a call for general comments

about any clause without suggesting alternative text

Difficulties users may have encountered with ISO 9001:2000,

with the opportunity to explain the nature of the

difficulty and suggest alternative text to address

the problems, along with a call for general comments

about any clause without suggesting alternative text

Any suggestions on how to improve ISO 9004:2000

Any suggestions on how to improve ISO 9004:2000

|

The International Organization

for Standardization is providing users of its ISO 9000:2000

series of quality management system standards with two online

initiatives: a user feedback survey to identify points for

improvement and an interpretation service to clarify the

intent of requirements.

“This support of users mirrors the evolution taking

place in the industrial and business sectors that our organization

serves,” says ISO Secretary-General Alan Bryden. “In

today’s competitive markets, a company cannot afford

to develop a product and just throw it over the wall to

customers. Many successful products are part of a total

package that includes support, maintenance and enhancement

services.”

The online feedback survey for users of ISO 9001:2000

and ISO 9004:2000 aims to improve the standards or develop

support documents to help users understand and implement

the standards. Any person with knowledge of or experience

with the standards may participate, and there’s no

limit to the number of participants from any organization.

The survey takes about 15 minutes to complete.

“Customer focus is one of the quality management

principles on which the ISO 9000:2000 series is based,”

continues Bryden. “Therefore, before launching the

development of the standards, ISO surveyed users for their

requirements and gave them the opportunity to ‘trial’

the standards during the development process. The recently

launched user feedback survey and interpretations service

demonstrates that ISO is continuing to put the customer

focus principle into practice.”

The survey is available at http://isotc.iso.ch/webquest/tc176/.

The interpretations service is intended to prevent ambiguous

and vague interpretations of the requirements of ISO 9001

and to develop a database of interpretations. It provides

interpretations related to what to do and not how to do

it, without changing any requirements of the standard or

its original intent. Requests for interpretations must be

submitted via ISO national member institutes.

The database, guidance on submitting a new request and

the official request form can be accessed at www.tc176.org/Interpre.asp.

ASQ Co-Hosts China Quality Conference

The American Society for Quality’s

Customer-Supplier Division and the China Association for

Quality will present the Third China-America Conference

on Quality Tools and Technologies Sept. 6-9 in Shanghai.

“We need to know the strengths as well as the weaknesses

of our trading partners,” states Dennis Arter, an

ASQ organizer. “Having been to China three times,

I’m beginning to understand the culture and the work

structures. Managing for quality is different in our two

countries. Trade with China offers a significant opportunity

as well as a challenge.”

The Shanghai event will be geared toward:

Learning about existing and future business relationships

in the People’s Republic of China

Learning about existing and future business relationships

in the People’s Republic of China

Exchanging ideas with professional colleagues in the world’s

fastest growing economy

Exchanging ideas with professional colleagues in the world’s

fastest growing economy

Learning about the government-industry structure in China’s

new market economy

Learning about the government-industry structure in China’s

new market economy

Introducing company products and services to China’s

market

Introducing company products and services to China’s

market

Gaining better understanding of ASQ and CAQ

Gaining better understanding of ASQ and CAQ

The fee of $3,600 for the full week includes airfare,

hotel accommodations, ground transportation and most meals.

Also included are cultural events in Shanghai and nearby

cities.

The CAQ serves quality professionals in the People’s

Republic of China. With headquarters in Beijing, CAQ offers

training, publications and support in the field of quality.

ASQ’s Customer-Supplier Division is a special interest

group aimed at exploring, expanding and communicating practices

that lead to effective supplier performance and increased

customer satisfaction. To learn more, visit www.asqcsd.org.

MetricStream Merges With Zaplet

MetricStream Inc., a developer

of enterprisewide quality software, has merged with Zaplet,

a provider of business process management solutions for

corporate compliance.

Shellye Archambeau, past CEO of Zaplet, has been named

CEO of MetricStream. Gunjan Sinha, former Chairman of MetricStream

will act as MetricStream’s executive chairman.

“Serving individual organizations separate solutions

for each of its compliance initiatives is a time-consuming

process,” explains Anil Gupta, vice president of marketing

for MetricStream. “It made sense to combine MetricStream’s

solutions with Zaplet in order to bring separately organized

compliance initiatives into one cohesive platform.”

For more information, visit www.metricstream.com.

Customer Satisfaction Can Equal

Failure

Philip Crosby Associates, a

consultancy touting the late quality guru Philip B. Crosby’s

Absolutes of Quality Management, has added another absolute

to the four originally coined by Crosby in his book Quality

Is Free (Mentor Books, 1992).

The new mantra comes two years after Crosby’s death.

It states, “The purpose of quality is to ensure customer

success, not customer satisfaction.”

“We are having a quality crisis in this country

because companies are narrowly focused on customer satisfaction,”

says Wayne Kost, president of PCA. “It has become

imminently clear that pursuing customer satisfaction can

be a surefire, direct route to corporate failure.”

The fifth absolute is designed to drive a stake through

the “customer satisfaction myth,” according

to PCA. “People can be satisfied with almost anything--happy

customers are not necessarily successful customers,”

explains Kost. “If you focus on satisfaction, you

will have short-term gains, but there’s a loss to

the customer. Fanatically focusing on customer success is

the only way to ensure corporate success. Building an organization

that knows how to focus on customer success and make it

a repeatable, continuous process is the next decade’s

primary challenge.”

A new book based on Crosby’s Quality Is Free

will cover this new absolute.

“No one is against quality, yet very few achieve

it,” adds Kost. “We took a hard look at the

original absolutes because we realized that a company could

live by them and still fail.”

Crosby defined the four absolutes as:

Quality has to be defined as conformance to requirements,

not as “goodness.”

Quality has to be defined as conformance to requirements,

not as “goodness.”

The system for causing quality is prevention, not appraisal.

The system for causing quality is prevention, not appraisal.

The performance standard must be zero defects, not “that’s

close enough.”

The performance standard must be zero defects, not “that’s

close enough.”

The measurement of quality is the price of nonconformance,

not indices.

The measurement of quality is the price of nonconformance,

not indices.

Learn more about Philip Crosby Associates at www.philipcrosby.com.

Best-Practice Lean Manufacturers

Recognized

The largest missile manufacturing

facility in the world, an appliance manufacturer and 10

automotive suppliers are recipients of the 2004 Shingo Prize

for Excellence in Manufacturing. Dubbed the “Nobel

Prize of manufacturing” by Business Week, the Shingo

Prize is the premier manufacturing award and recognition

program in North America.

Notable achievements of the 2004 recipients include:

Seven of the 12 winners achieved product quality of fewer

than 10 returned parts per million opportunities.

Seven of the 12 winners achieved product quality of fewer

than 10 returned parts per million opportunities.

Seven of the 12 recipients have inventory turnover rates

greater than 25 per year, compared to a U.S. average of

eight.

Seven of the 12 recipients have inventory turnover rates

greater than 25 per year, compared to a U.S. average of

eight.

Premium freight as a percent of production costs averaged

0.12 percent.

Premium freight as a percent of production costs averaged

0.12 percent.

“Once again, the recipients of the Shingo Prize

demonstrate that they are prepared to weather economic uncertainty

by not wasting precious manufacturing and business resources,”

notes Ross Robson, Shingo Prize executive director. “Shingo

Prize recipients and lean manufacturers clearly stand out

among North American manufacturers in terms of quality,

cost, delivery and business results.”

This year’s recipients are:

ArvinMeritor Light Vehicle Systems-- Gladstone plant, of

Columbus, Indiana

ArvinMeritor Light Vehicle Systems-- Gladstone plant, of

Columbus, Indiana

Delphi Corp.--Delphi Electronics and Safety, Delnosa 5 and

6 Operations, of Reynosa, Mexico

Delphi Corp.--Delphi Electronics and Safety, Delnosa 5 and

6 Operations, of Reynosa, Mexico

Delphi Electronics and Safety--Kokomo Operations, Plants

7 and 9, of Kokomo, Indiana

Delphi Electronics and Safety--Kokomo Operations, Plants

7 and 9, of Kokomo, Indiana

Delphi Corp.--Energy and Chassis Systems, of Empresas Ca-Le

de Tlaxcala, Mexico

Delphi Corp.--Energy and Chassis Systems, of Empresas Ca-Le

de Tlaxcala, Mexico

Delphi Corp.--Packard Electric Systems, Plant 50, of Del

Parral, Chihuahua Mexico

Delphi Corp.--Packard Electric Systems, Plant 50, of Del

Parral, Chihuahua Mexico

Delphi Sistemas de Energia S.A. de C.V., Plant 57, of Chihuahua,

Mexico

Delphi Sistemas de Energia S.A. de C.V., Plant 57, of Chihuahua,

Mexico

Delphi Corp.--Packard Electric Systems, Plant 58, of Meoqui,

Chihuahua, Mexico

Delphi Corp.--Packard Electric Systems, Plant 58, of Meoqui,

Chihuahua, Mexico

Delphi Packard--Centro Tecnico Herramental S.A. de C.V.,

Plant 98, of Ramos Arizpe, Coahuila

Delphi Packard--Centro Tecnico Herramental S.A. de C.V.,

Plant 98, of Ramos Arizpe, Coahuila

Delphi Packard, Plant 51, of Nuevo Casas Grandes, Chihuahua,

Mexico

Delphi Packard, Plant 51, of Nuevo Casas Grandes, Chihuahua,

Mexico

Maytag Jackson Dishwashing Products of Jackson, Tennessee

Maytag Jackson Dishwashing Products of Jackson, Tennessee

Raytheon Missile Systems--Tucson Operations, of Tucson,

Arizona

Raytheon Missile Systems--Tucson Operations, of Tucson,

Arizona

TI Automotive of Cartersville, Georgia

TI Automotive of Cartersville, Georgia

The Shingo Prize is administered by the Utah State University

College of Business. Awards will be presented at the 16th

annual Shingo Prize Conference and Awards Ceremony, May

20 in Lexington, Kentucky. To learn more, visit www.shingoprize.org.

Overseeing Unfamiliar Projects

Common Among Managers

Learning by leading is a popular

concept in many offices, a new survey suggests. About 40

percent of executives polled in the recent survey said it’s

common for managers to oversee projects for which they have

limited experience.

Executives were asked, “How common or rare is it

for managers at your firm to oversee projects for which

they have limited experience?” Forty-seven percent

said it’s somewhat rare; 33 percent said it is somewhat

common.

The poll includes responses from 150 senior executives--including

those from human resources, finance and marketing departments--with

the nation’s 1,000 largest companies. It was conducted

by an independent research firm and developed by Accountemps,

a specialized staffing service for temporary accounting,

finance and bookkeeping professionals.

“Many leadership skills--such as the ability to

motivate people and inspire motivation--are transferable,

and companies frequently ask experienced managers to oversee

a range of initiatives, including those outside their immediate

expertise,” explains Max Messmer, chairman of Accountemps.

“This is especially common as firms strive to maintain

productivity despite leaner staffing levels.”

Messmer notes that managers who take on assignments outside

of their scope often work harder to win employee trust.

“Staff members may initially be skeptical of leaders

who come from outside the ranks,” he says. “Managers

in this situation must show that they value their team’s

expertise and encourage everyone working on the project

to share ideas and information.”

Messmer offers four tips for reducing the learning curve

on new projects:

Let the experts be the experts. Rely on your team

for its knowledge and tactical skills, and focus your efforts

on motivating employees and keeping projects on track.

Let the experts be the experts. Rely on your team

for its knowledge and tactical skills, and focus your efforts

on motivating employees and keeping projects on track.

Don’t rush to judgment. Avoid making quick

decisions. Instead, consider the situation from several

different angles and gather feedback before establishing

a plan.

Don’t rush to judgment. Avoid making quick

decisions. Instead, consider the situation from several

different angles and gather feedback before establishing

a plan.

Take all perspectives into account. Solicit various

viewpoints but don’t be unduly influenced by one or

two team members.

Take all perspectives into account. Solicit various

viewpoints but don’t be unduly influenced by one or

two team members.

Give credit where it’s due. Thank employees

and co-workers who share insights and give them credit for

their ideas.

Give credit where it’s due. Thank employees

and co-workers who share insights and give them credit for

their ideas.

|