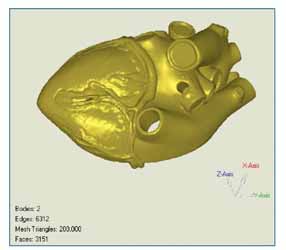

Creating Complex Models with 3-D Scanning Creating Complex Models with 3-D Scanning

GKS Inspection Services' RPS 150 Laser Probe

Ayotte Design Inc., a Newburyport, Massachusetts, provider of product and machine design services, had a manufacturing client that wanted to modify an existing plastic resin heart to demonstrate a new cardiac device. The medical device company required modifications on the model to fit the new product and then needed to manipulate it with computer-aided design (CAD) software to create the demonstration piece. The process presented several problems. "The heart model was a tricky, amorphic shape, which is difficult to scan with a contact process," says Gary Ayotte, president of Ayotte Designs. It also had an irregular internal, partially open cavity, the scan of which needed to be very accurate, as it would have to exactly fit the company's new device.

Ayotte contacted Larry Carlberg, a regional manager at GKS Inspection Services, a division of Laser Design Inc., to figure out how best to create the scan of the resin heart.

Full Story...

|

Streamlining Measurement Streamlining Measurement

CogniTens' Optigo Measurement System

Ogihara America Corp. is a tier one automotive supplier and one of the largest independent automotive die manufacturers in the world. A Japanese company, it operates two U.S. facilities: one in Howell, Michigan, and another in Birmingham, Alabama. Ogihara's facilities all over the world share consistent, lean operations, and the company has made a longstanding, continuous effort to improve its operational performance.

The company wanted to lower customer-reported quality issues and to maintain best-quality ratings by transforming reactive quality processes into proactive ones. To that end, Ogihara conducted a thorough evaluation of its quality processes and systems and found that it needed to integrate its product development and manufacturing programs. This called for a dimensional measurement system that could operate in a shop floor environment and help resolve quality concerns using root cause analysis. Ogihara had trouble finding a product that met these demanding needs.

Following a long evaluation and bench-marking period Ogihara identified CogniTens' Optigo, CoreView Pro and Off-Line Measurement products as the only noncontact measuring system capable of meeting its criteria.

Full Story...

|