ISO 14001 Revisions to Be Published Soon

The revised ISO 14001 standard is scheduled to be published by the end of the year, bringing significant changes to environmental management professionals.

According to the International Organization for Standardization, the changes to the standard aim to clarify it and make it more user-friendly. Additionally, it aligns some clauses with ISO 9001:2000. Among the proposed changes are:

Requirements to define the scope of the environmental management system ( EMS) by describing the included operations, activities, products and services Requirements to define the scope of the environmental management system ( EMS) by describing the included operations, activities, products and services

Requirements to document the evaluation of how an EMS meets the standard’s requirements Requirements to document the evaluation of how an EMS meets the standard’s requirements

Documentation that auditors satisfy the standard’s requirements for competence Documentation that auditors satisfy the standard’s requirements for competence

New definitions of pollution, which is described in the revised standard as being the “creation, emission and discharge of any type of pollutant” New definitions of pollution, which is described in the revised standard as being the “creation, emission and discharge of any type of pollutant”

Requirements that environmental performance improvement be demonstrated in the EMS (rather than the focus being on improving the management system) Requirements that environmental performance improvement be demonstrated in the EMS (rather than the focus being on improving the management system)

Connie Glover Ritzert, chairperson of the U.S. SubTAG 1 to TC 207, reports that the U.S. delegation to the technical committee that developed the revisions opposed adding new requirements to the 1996 version of ISO 14001, but that position was in the minority on the TC.

“The general opinion expressed in the most recent US SubTAG 1 meeting was that the revised standard [is] not really more clear than the 1996 version,” Ritzert states. “There was also general agreement, however, that the revised standard could be implemented without major problems by most organizations.

“The revised ISO 14001 is not perfect. It is not exactly the standard we would have written in the U.S. It is, however, a consensus standard for the ISO process, and I continue to support the use of this international consensus EMS standard for the value it brings to environmental management.”

Along with minor changes in wording relating to the notification about an EMS to subcontractors, temporary staff and permanent employees, the draft revision also includes more major changes, such as a requirement that registered companies establish external communication systems about their EMS, an expanded list of documents registered companies have to keep, and a clarified requirement that management should “ensure the availability of resources” essential to the EMS, rather than simply “provide resources” for it.

For more information, visit www.iso.org.

Administrators Grow Quality in Schools Administrators Grow Quality in Schools

School administrators looking for ways to meet tough federal requirements have found a new ally--the quality profession.

The need for continual improvement is familiar to quality professionals, but it’s relatively new to the education community. The No Child Left Behind Act, signed into law in early 2002, includes requirements for school districts to have improvement plans and processes. That’s where the American Society for Quality comes in.

ASQ’s Koalaty Kid division recently started consulting with school districts looking to meet federal requirements and improve the quality of their administrative processes. The results have been dramatic.

“The training approach really gives [administrators] the ability to focus on the root causes of problems and the ways to fix them in the short term and the long term,” says ASQ education market manager Suzanne Keely.

The training uses W. Edwards Deming’s plan-do-study-act (PDSA) cycle to show administrators how to get to the root causes of problems. It’s often foreign to them until they see the benefits the methodology brings.

“Instead of using improvement tools in isolation, it shows them how all of their processes can be improved,” explains Keely. “A lot of administrators tell me that they used to have meetings, flowchart a problem and then go out and fix certain things to solve it. But the PDSA cycle is different. It’s not just random acts of improvement.”

More school districts are interested in quality training since the No Child Left Behind Act was passed. Additionally, the 2003 Baldrige Award win by Community Consolidated School District 15, of Palatine, Illinois, made quality principles more visible in education. The district, which started using the Baldrige criteria nine years ago after its then-superintendent met with executives from Motorola, uses a stakeholder-driven quality effort and the PDSA cycle to establish student performance targets. Process-oriented thinking allows the district to meet or exceed every one of them.

“It hasn’t been easy to meet the requirements we’ve set for ourselves, but the results are outstanding,” says Bob Tenczar, CCSD 15 communications director. “We just decided that if we really wanted to improve, we would use the same processes as some of the best companies in the business world.”

Since its Baldrige win, the district has been overwhelmed with requests for information from other school districts about the process. CCSD 15 administrators have been all over the country talking to other districts about the process.

ASQ’s Koalaty Kid training is available in seminars and/or six-day on-site training, where consultants create a customized PDSA cycle for the district.

“[Quality improvement] principles are very powerful tools in the education industry,” Keely says. “You have to see what needs to be changed before you can show improvements, and Deming’s approach works.”

For more information, visit www.ccsd15.net or www.asq.org/edu/kkid.

QMI Acquires QCB, Becoming Largest North American Registrar QMI Acquires QCB, Becoming Largest North American Registrar

With the recent acquisition of Quality Certification Bureau Inc., QMI is now the largest registrar in North America.

The buyout includes QCB Inc., QCB World Corp. and QCB Organic, companies that are collectively based in Edmonton, Alberta, Canada. QMI now has more than 10,700 certificates serviced by more than 400 employees.

Customers will notice little change as the companies are merged.

“QMI and QCB have built strong reputations both here and abroad as respected registrars providing premier customer service,” says Wendy Tilford, QMI president. “Acquisition is a significant element of our growth strategy and QCB is an excellent fit.”

For more information, visit www.qmi.com.

Survey Reveals OEMs and End Users Are More Alike Than Different Survey Reveals OEMs and End Users Are More Alike Than Different

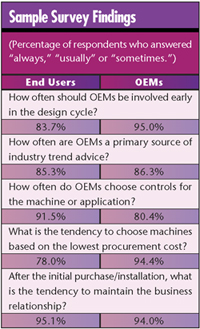

Original equipment manufacturers and end users think similarly about how to improve their relationships, according to a new study conducted by Rockwell Automation Inc. and Penton Media Inc.

The study, based on interviews with 582 OEMs and end users, compared the views of the two groups on important relationships issues such as design cycle responsibilities, buying behaviors and communication channels. It revealed that the groups have similar views on OEMs. For example, 86.3 percent of OEMs and 85.3 percent of end users believe that OEMs are a primary source of advice on industry trends.

The most divergent responses pertained to questions about procurement costs. Almost 95 percent of OEM respondents believe that end users tend to choose machines and components based on cost, while only 78 percent of end users agree.

The study suggests that OEMs and end users can improve their relationships by having better channels of communication, involving OEMs early in the design cycle and providing more customer support. One-third of OEMs and end users suggested that having a better understanding of design specifications is key to enhancing the business relationship.

“It’s difficult to stay on top of all the new technology, regional and global standards, industry regulations, company-

specific requirements and other manufacturing considerations,” says Doug Burns, Rockwell Automation global OEM business development director. “OEMs and end users need a methodology for developing and building to a specification, so everyone is on the same page and moving in the right direction.”

For more information, visit www.rockwell.com.

Hexagon Acquires Romer CimCore

Worldwide engineering group Hexagon AB got even larger recently with the acquisition of Romer CimCore Inc.

Romer CimCore, a U.S. corporation with research and development and manufacturing operations in Farmington Hills, Michigan, and Carlsbad, California, is Hexagon’s second acquisition in as many months. Hexagon bought Romer S.A., which is based in France, in July. Romer S.A. and Romer CimCore were founded as a single company in 1986 and split in 1999. Romer CimCore, a U.S. corporation with research and development and manufacturing operations in Farmington Hills, Michigan, and Carlsbad, California, is Hexagon’s second acquisition in as many months. Hexagon bought Romer S.A., which is based in France, in July. Romer S.A. and Romer CimCore were founded as a single company in 1986 and split in 1999.

“Our interest in finding a strategic partner to help take our business to the next level has been realized in Hexagon Metrology,” says Romer CimCore President Hank Kraus. “We couldn’t have asked for a more appropriate partner in terms of financial strength, technical resources and market opportunities.”

Hexagon spokesman Bill Fetter reports that the new parent company plans to keep approximately 60 employees currently working in Romer CimCore’s Michigan and California facilities. The terms of the acquisition are being kept private.

By remerging Romer CimCore and Romer S.A., Hexagon hopes to form a worldwide supplier of technical innovation with all the marketing capability Hexagon already has, according to Hexagon President and CEO Ola Rollèn. Additionally, Hex-agon plans to adapt its PC-DMIS software to fit Romer CimCore’s products.

“By merging the two companies, Hexagon will create a strong R&D organization that in turn will result in a quicker product launch pace for portable measurement systems,” Rollèn says.

Romer CimCore is a leader and innovator in portable metrology. It manufactures and markets equipment used in industries such as automotive and aerospace, among others. The company’s clients include The Boeing Co., Caterpillar Corp., DaimlerChrysler, General Electric and Toyota Motor Corp. Romer CimCore’s main product is the articulated arm, used in a variety of industries to measure objects in 3-D.

Company founder Homer Eaton will stay at Romer CimCore as the head of R&D. Eaton reports he is excited about the acquisition.

“Romer has a lot of exciting projects ongoing that will benefit greatly from the additional resources and talent available within the Hexagon group,” Eaton says. “We look forward to collaborating with the group’s metrology companies around the world.”

For more information, visit metrology.hexagon.se.

Quality News From China: Quality News From China:

New Quality Assessment Tool Breaks Ground

The Shanghai Academy of Quality Management recently announced the first assessment guidelines for the Chinese service industry.

The Service Quality Index was formulated by a two-year research program. It can be used to assess service quality and highlight areas for improvement in the customer service departments of almost any company--from carrier companies to banks and stock exchanges. The Institute of Scientific and Technical Information of Shanghai underwrote the intellectual property rights of SQI.

Because service isn’t a tangible asset, assessing its quality has long been a problem for researchers. Tang Xiaofen, president of the Shanghai Academy of Quality Management, observes that while the quality of service has until now been measured with the Customer Satisfaction Index, that approach focuses only on a customer’s perception of service and ignores a service provider’s capabilities. Therefore, it lacks the information needed for improvement. However, SQI overcomes these deficiencies.

SQI provides a process index, capability index and performance index of service quality. Shanghai Urban Power Co., the first company to be examined using the process, scored a 96.01 in performance, but its process and capability indexes were much lower--83.02 and 78.14, respectively. The differential indicates that the company needs to improve its capability to improve overall performance. Accordingly, the company made progress in solving some of the problems the assessment highlighted: debt collection, planning and managing, equipment operation and marketing.

SQI passed an examination by the Commission of Science and Technology, a division of Shanghai’s municipal government, and is now being applied at train stations, an international airport, a department store and a gas supplier. It was also awarded a Shanghai Science and Technology Advancement Award in 2003.

American-Chinese Standardization Agreement Makes History American-Chinese Standardization Agreement Makes History

An American firm made history recently when it became the first U.S. standards development organization to sign an agreement with the national standards body of China.

It happened in Beijing, when senior officials from ASTM International and the Standardization Administration of the People’s Republic of China (SAC) signed a memorandum of understanding (MOU) to strengthen the relationship between the two organizations. The signing, along with participation in standardization workshops held in Beijing earlier in the week, is the latest event in ASTM’s ongoing involvement in Chinese standardization. The MOU will enhance the ability of SAC and ASTM International to support the needs of the Chinese people and aid in the development of Chinese national standards for health, safety and the environment.

“ASTM standards have a century of history in the world’s marketplace helping to ensure good quality products and accurate testing procedures,” states Jim Thomas, ASTM International president. “The signing of this MOU with the SAC is a great step forward to encouraging greater access to ASTM standards in China as well as a bigger voice by Chinese exports in the content of ASTM standards.”

In the MOU, the organizations agree to explore opportunities for standards development in areas of mutual interest, promote communication and share knowledge, and promote greater Chinese participation into ASTM standards development processes. In addition, ASTM agrees to provide its full collection of standards to SAC, jointly sponsor standards and training programs, and provide membership of SAC representatives on ASTM technical committees.

In return, SAC will promote the acceptance and use of ASTM standards in China, use ASTM International’s resources to develop Chinese standards, link ASTM’s Web site on SAC’s home page and reference ASTM in new Chinese standards.

ASTM International has had a presence in China for many years. Its involvement includes agreements with other standards organizations, including the Chinese National Institute of Standardization and the Shanghai Institute of Standardization. In addition, ASTM has published an annual Chinese version of its magazine, Standardization News, since 1991.

For more information, visit www.astm.org.

|