| by John D. Brown

Remember when computing technology improved so fast your new computer became obsolete as soon as you took it out of the box? Digital photography and imaging technology are currently setting a similar developmental pace. New products combining the best of both are transforming the way real-time and shop floor measurements are taken. Portable, versatile and durable--add wireless capability to that list and digital measurement technology presents a pretty picture indeed.

Metrologists, engineers, surveyors, manufacturers, scientists and quality control technicians employ many types of measurement technologies in their individual disciplines, and photogrammetry is one of them. It’s a 3-D coordinate measuring technique that uses photographs as a fundamental medium for metrology. For more than 100 years, photogrammetry has helped civil engineers and surveyors measure objects as well as create large, 3-D topographical mapping systems. Industrial engineers use close-range photogrammetry for in-place measurement, tooling inspection and adjustment, test/retest measurement, deformation studies, part inspection, and disassembly and reassembly. Such diverse industries as aerospace, automotive, shipbuilding, power generation and construction have used the technology.

Triangulation is the fundamental principle underlying photogrammetry. By taking two photographs from at least two different locations, “lines of sight” can be developed from each camera to points on the object. These lines, sometimes called “rays” due to their optical nature, are mathematically intersected to produce 3-D coordinates of the points of interest.

Although film photogrammetry has been around for decades, recent advancements in digital photographic technology have ushered in innovations that would have been impossible with film techniques. To better understand photogrammetry’s new technology, we’ll take a look at the INCA3 digital camera from Geodetic Systems Inc. This camera combines an ultra high-resolution CCD sensor with a compact industrial computer to capture field measurements with high accuracy, even in industrial settings. The camera features numerous innovations, including an integrated strobe, automatic exposure, advanced calibration features and wireless capabilities for unfettered operation and immediate online connectivity. An entire pack-and-go system with camera and notebook computer can weigh less than 13 pounds and be carried onboard an airplane or checked as standard baggage.

These cameras can operate independently of the computer either by hand or remote control. Digital pictures can be saved to a compact flash memory card, then downloaded to the computer at a later time. The camera can also be connected to a computer wirelessly or directly via a thin power/network cable. Either way, each photograph can be measured immediately after it’s taken. It’s also possible to simultaneously operate multiple cameras online for real-time measurement of dynamic or static objects. Whether the camera is offline or online, it processes images immediately after each picture is taken so problems can be detected instantly during the session. The embedded PC rapidly compresses images--typically greater than 10:1--to increase disk capacity and provide faster data transfer.

Once photographs are taken, image-processing software automatically inspects the collected digital pictures and extracts the required 3-D data. The data can then be aligned into a 3-D coordinate system and used for surface inspection operations, compared to previous measurements, or examined further using the software’s built-in analysis, visualization and statistical tools. The software’s graphical interface allows the operator to view points, camera stations, intersection angles, surfaces and more. The user can also view text showing point XYZ coordinate information and analysis results. Moreover, 3-D coordinate data can be exported in a variety of CAD file formats.

Photogrammetry technology is best suited for in-place measurement and inspection of large objects in industrial settings where vibration, movement and extreme temperatures are often found. Unlike other technologies, such as laser trackers or theodolites, digital photogrammetric systems allow precise measurements while the operator is standing on a wavering or unstable floor, or from a lift or scaffolding on the plant floor. Equally immune to harsh conditions in outdoor environments such as shipyards and remote space antenna fields, a photogrammetric camera can gather 3-D data of laboratory quality and accuracy without the lab conditions required by other metrology instruments.

A shop floor or assembly line presents many problems for quality control personnel. It isn’t easy to measure and record data from large assemblies (e.g., aircraft, automobiles, space hardware) and processes during production. A typical setting includes workers, tools, equipment, cabling channels and numerous obstructions that impede the line of sight. But thanks to the portability found in this new generation of digital cameras, operators can shoot field measurements with minimal production disruption and downtime.

To put this process in perspective, compare it to any picture-taking situation--a vacation, for instance. A photographer arrives on the scene and sizes up the subject and the surrounding environment. Will trees, buildings or power lines obstruct the view? What location provides the best viewpoint to the subject? Is part of the subject completely hidden, requiring a few shots taken from a roof? Given the visual issues that exist in any setting, the photographer can always move the camera to the best line of sight and get the optimum photograph. The portability and ease of point-and-shoot cameras provides endless possibilities for photography, for both hotojournalism and private occasions.

In the same way, photogrammetry transforms the plant floor into a place where metrology adapts to the production line in a practical way. This interaction revolves around working people and productivity. With the least amount of impact to others working in the same environment, a quality technician can use a photogrammetric camera to gather critical coordinate data, perform analysis, break down assessments and make adjustments--all within the confines and roadblocks of a busy manufacturing environment.

Mobility, speed, high accuracy and adaptability to local space restrictions are photogrammetry’s strong suits. The technology has been used successfully on land, on and under the ocean, in the air, even in outer space, on objects as small as a football or larger than a football field.

Measuring industrial objects with photogrammetry usually consists of the following steps:

1. Plan the measurement

2. Target the object

3. Take pictures

4. Measure pictures

5. Process pictures to obtain 3-D coordinate data

6. Analyze the results

Because every measurement project is unique, the content and order of these steps might change depending on project requirements and user preference. For some jobs, the photographer will shoot all the photos first to minimize time on-site and then measure them later. Other quality control tasks require the operator to shoot and measure each picture immediately after it is taken. An operator might also choose to take and measure a few photographs, then process them instantly for preliminary results that will make the remaining pictures easier to measure. Regardless of their order, all the steps listed above are carried out in some fashion for every project.

For photogrammetry to work, specific points must be identified on the object to be measured. Typically these are special targets made of grayish, retro-reflective material that is just 0.1 mm thick. This material, which resembles highway reflectors, is typically 100 to 1,000 times more efficient at returning light to the source than a white target.

A photogrammetric camera doesn’t measure the object directly but rather the center of the retro-reflective target. By placing the target on or in a known relationship to the point of interest, the point can be measured. In some circumstances, it can be difficult to directly target the point you want to measure. Fortunately, many different types of retro-reflective targets have been developed to solve this issue.

Feature targets represent a recent advance in this area. They can be used to quickly and automatically measure planes, edges, corners and pins. For example, in the automotive industry, feature targets are used to measure numerically controlled blocks and pins. These targets consist of a specially made adapter that attaches to the feature. On the adapter is a pattern called a “coded target.” The relationship of the coded target to the desired feature is determined by a one-time calibration.

When manufacturers implement target points into their product designs, measurement becomes even more efficient. Quality techs can easily track target points specifically designed into the CAD model and machined directly into the tooling. These precision-made tooling targets are located in bushed holes, or they might be defined by features on the measured object--such as part edges or hole locations--that are targeted in some way.

Once an object is targeted, the camera’s low-powered flash illuminates the targets and makes their exposure independent of the ambient light level. This means the object can be photographed in bright light or total darkness, and the target exposure will remain the same. Therefore, target and object exposure are largely independent; target exposure is provided by the strobe and object exposure provided by the ambient light. Because of the camera’s integrated strobe and PC, the exposure can be set automatically, ensuring proper exposure every time.

While targeting has long served as photogrammetry’s mainstay, new developments in the technology give quality technicians effective ways to capture points of interest on an object. For example, with a multiple-camera system, hand-held probes can now actually touch these points on the object. These small, lightweight and wireless probes come in several configurations and can use interchangeable CMM tips. When used with probes, a photogrammetry system transforms into a portable, hand-held CMM.

New noncontact measurement techniques using specially developed projectors can project thousands of dots (i.e., targets) on an object’s surface instead of, or in addition to, targets mounted to the object. These devices can measure static objects by taking photos of the projected targets from various locations. In this mode, the projector and the measured object must be stable during the brief period of photography. However, when used with two synchronized cameras and a stroboscopic light source, the system can “freeze” the dots on the object and accurately measure moving objects or objects undergoing deformation. Even parts moving down an assembly line can be measured in this way.

The high-speed synchronization of cameras and projectors also means they don’t have to be firmly mounted and can be used just about anywhere. A photogrammetry system could be mounted on a cherry picker, for example, and used to measure the top of an airplane.

A projector’s spot brightness depends on several factors, including the measured object’s color, shininess, curvature and distance from the camera. Together these factors determine how large an area can be measured in a single setup. As a rule of thumb, an area about 20 ft in diameter can be measured in a single setup if it’s white, flat in finish and approximately flat in shape. An area about 2 ft in diameter can be measured if the measured object is black, shiny and convex.

Projected targets aren’t directed to a particular location. The projector slide has a nominal grid of targets projected onto the measured object, and they fall where they fall. Thus, it’s suitable for characterizing a surface’s shape but not for measuring particular features such as holes or edges. However, probes or feature targets can quickly and accurately measure such features.

Photogrammetry provides accuracies comparable to those achieved by other large-volume, high-accuracy portable coordinate measurement systems. Typical accuracies are 25 to 50 µm (0.001 to 0.002 in.) when completely viewing a 15 ft area (in such a case, the camera would be roughly 15 feet from the object).

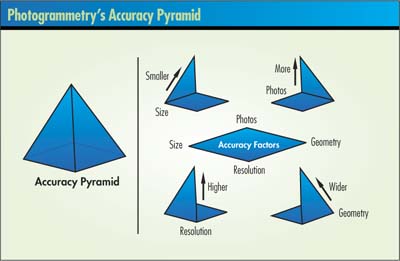

However, photogrammetric accuracy depends on several interdependent factors:

Camera resolution Camera resolution

Size of the area being viewed/photographed (corresponds to camera-to-object distance) Size of the area being viewed/photographed (corresponds to camera-to-object distance)

Number of photographs taken Number of photographs taken

Geometric layout of camera stations (i.e., camera locations) relative to the object and each other Geometric layout of camera stations (i.e., camera locations) relative to the object and each other

Based on these factors, accuracies can vary. Their effects are illustrated in the figure above. To get higher accuracy (i.e., a higher pyramid), you need more of the items shown on the lines of pyramid (e.g., higher resolution, smaller area under view, more photos or wider geometry). As a rule of thumb, if you take six to eight photographs with good geometry, and each photograph captures the entire object, you should obtain accuracies of 25 µm on a 15 ft field of view.

Modern photogrammetry systems offer cutting-edge advancements with automated repeatability measurement software. Automated repeatability measurement is composed of advanced 3-D data collection and analysis functionality, including automatic data processing. With this technology, users such as automobile manufacturers are able to quickly and accurately study everything from headlight assembly to the effects of welding on an auto’s body structure.

The test/retest method used by ARM allows a metrologist to test a tool or even a hand-applied process for repeatability. Tests that weren’t feasible with other types of CMMs are easily conducted with photogrammetry. Unlike a CMM measurement point, a photogrammetry target stays on the part in the same location as it is removed and replaced. Because of this, an engineer or quality technician can track planar movement rather than just hard features such as holes, edges and slots. Although ARM is ideal for automotive applications, it can also be used in a variety of industries and applications such as deformation analysis, part-loading studies and assembly operations.

The tremendous advances in digital technology have spawned ultra high-resolution digital cameras and colossal increases in computing power. These developments have helped to launch a photogrammetric revolution for new industrial measurement processes. Thanks to this technology’s exceptional portability, quality departments can perform dimensional maintenance and inspection in places where other metrology instruments can’t. Not surprisingly, photogrammetry has earned a respected position in metrology. As metrologists and engineers create and expand their current inspection routines, photogrammetry will continue to provide solutions for customer needs while advancing industrial measurement.

For the past 20 years, John D. Brown has been involved in the planning and execution of hundreds of photogrammetric projects for diverse industrial measurement applications. Brown leads the new market development division of Geodetic Systems Inc.’s digital photogrammetry solutions for the manufacturing marketplace.

|