by John R. Grum

In their ongoing quest to build

a better mousetrap, software developers have combined calibration

management with the latest business process developments

to create an improved system for controlling calibration

and maintaining measurement instrumentation. However, this

breakthrough technology is driven by stringent requirements

that companies ignore at their peril. Quality standards

such as ISO 9001, ISO/IEC 17025 and ISO/TS 16949; regulatory

requirements such as the FDA’s code of federal regulations’

requirements for current good manufacturing practices; and

everyday business goals such as profitability all have a

bearing on the latest trends in calibration management systems.

Similarly, compliance to ISO/IEC 17025 underlies many

manufacturing requirements. This standard, mandated by ISO/TS

16949 for calibration service providers, is gospel for original

equipment manufacturers. It includes calibration basics

along with environmental conditions, measurement uncertainty,

proper certificate preparation, calibration technician training

and technical competence, and standard operating procedures

such as change control.

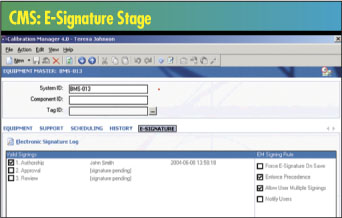

For FDA-regulated companies, compliance to the FDA’s

cGMP drives overall manufacturing requirements, just as

compliance with 21 CFR Part 11 drives electronic records

requirements. These include using validated computerized

systems; retaining secure electronic records; system and

data security; system access control; using secure electronic

signatures; and user-independent, computer-generated, time-stamped

audit trails.

Historically, a CMS provided basic tracking, scheduling

and reporting functions. Modern packages offer flexibility

and customization to ensure they’ll fit into existing

calibration processes. New capabilities include tracking

full measurement, calibration and maintenance data; multiple-event

scheduling; multiple security levels; and attaching standard

operating procedures, certificates, charts and forms to

asset records.

New CMS features integrate the latest trends in calibration

management with those of business processes, including:

Advancing software technologies

Advancing software technologies

Assessing new architecture technologies

Assessing new architecture technologies

Outsourcing calibrations

Outsourcing calibrations

Collecting field data

Collecting field data

Measuring performance

Measuring performance

Centralizing calibration across the enterprise

Centralizing calibration across the enterprise

Standardizing calibration between sites

Standardizing calibration between sites

As regulations become more defined and internal processes

are re-evaluated, a modern CMS can increase productivity,

manage compliance and improve your organization’s

return on its investment. However, upgrades in database,

report writing and operating system software must be accommodated

by the CMS.

The first step in migrating to a new system is evaluating

needs through a user-requirement specification. This is

a simple statement of what’s required of the system.

By defining the requirements necessary for the calibration

management process, an organization can narrow the search

for the CMS best suited to its needs. Guidelines for the

URS process include:

Emphasizing the required function rather than the method

for implementing it

Emphasizing the required function rather than the method

for implementing it

Writing a URS for each function the software will perform

Writing a URS for each function the software will perform

Ensuring the URS will distinguish between regulatory requirements

and desirable features

Ensuring the URS will distinguish between regulatory requirements

and desirable features

Once the URS is completed, it can be evaluated against different

CMS packages and an educated decision made about which is

most suitable. Although the process takes time, it helps

to ensure a close match between the user’s requirements

and the CMS. Other considerations include flexibility, ease

of use, reliability and, most important, the technology

upon which the system is based.

The technology a CMS vendor uses to develop a software

package is crucial. Verifying that the CMS is designed for

Microsoft SQL Server or Oracle isn’t enough; organizations

must look at the type of architecture used. Growing companies

should evaluate whether the software package is scalable.

A CMS requires a significant investment of time and money,

and it can’t be changed every year to optimize productivity.

Therefore, manufacturing companies must evaluate the vendor’s

development practices to confirm they’re developing

not only for today but also for tomorrow.

CMS vendors are quick to take advantage of new technology

to produce state-of-the-art systems. Such software packages

provide not only best-in-class feature sets but also the

ability to share data in seconds with hundreds of users

from multiple locations.

The technology best equipped to satisfy these requirements

is an n-tiered Web model designed to distribute the necessary

user interaction, computation and storage tasks between

the layers of the architecture. Although some latitude exists

in the exact number and structure of layers, a CMS is typically

broken up into a client tier, a middle tier and a data store--which

is further segmented into a data abstraction layer and a

database server.

Client tier. This layer is responsible for interactions

with the user. In the past, all application users saw the

same interface. Today’s users access their data from

a variety of devices with various screen sizes and input

methods. The client tier must accommodate the user regardless

of the device bridging the user to the system.

Client tier. This layer is responsible for interactions

with the user. In the past, all application users saw the

same interface. Today’s users access their data from

a variety of devices with various screen sizes and input

methods. The client tier must accommodate the user regardless

of the device bridging the user to the system.

Middle tier. Also known as the business logic

layer, the middle tier is where data are interpreted and

business rules applied. Certain types of security and access

checks are also performed at this level. The middle tier

is considered the brain of the n-tiered system; a Web server

offers the best performance.

Middle tier. Also known as the business logic

layer, the middle tier is where data are interpreted and

business rules applied. Certain types of security and access

checks are also performed at this level. The middle tier

is considered the brain of the n-tiered system; a Web server

offers the best performance.

Data store. This tier includes the task of data

storage and retrieval. Once the choice of a database server

is made, a data abstraction layer is created to provide

the interface between the middle tier and the database itself.

Some popular databases include Microsoft SQL Server and

Oracle. For its reliability, MSDE is now frequently used

instead of Microsoft Access.

Data store. This tier includes the task of data

storage and retrieval. Once the choice of a database server

is made, a data abstraction layer is created to provide

the interface between the middle tier and the database itself.

Some popular databases include Microsoft SQL Server and

Oracle. For its reliability, MSDE is now frequently used

instead of Microsoft Access.

By using a Web-based, n-tiered architecture, CMS software

greatly reduces network traffic and the burden on client

resources while maintaining security and data integrity.

Users aren’t directly bound to the data store, as

they are with a traditional client-server application. Instead,

the middle tier uses connection pooling to enhance both

network and software resources. The result is improved performance.

In traditional Microsoft Access database applications,

the system slows down as more users log onto the software.

Data corruption is typical. With this modern architecture,

a CMS can handle hundreds of users without affecting performance.

Moreover, as an organization grows, so must its CMS. Application

scalability is very important; among other things, it means

tremendous cost savings when multiple sites are rolled into

one system.

One of the biggest trends in manufacturing is outsourcing

calibration chores. Limitations in time and human resources

generally motivate companies to consider this option. Because

a company might outsource all or only a few calibration

services, outsourcing itself falls into several categories.

The first consists of using a particular company to calibrate

specific equipment, which is gathered and routinely sent

off-site. The second involves having a company--such as

the manufacturer--service and calibrate the equipment. The

third is contracting a calibration service company to calibrate

the entire inventory on-site. Most companies use a combination

of these categories.

Regardless of who provides the calibration services, the

manufacturing company is responsible for managing and recording

calibrations. A state-of-the-art CMS provides the tools

to do this. It can track scanned certificates of completed

calibrations, equipment status and location, and reports

of money spent on outside calibrations. Metrics on service

provider performance are also important factors.

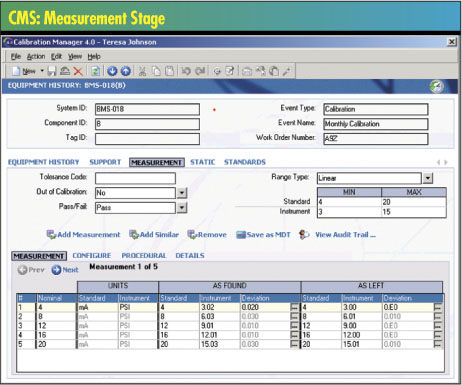

Collecting and managing both manufacturing and laboratory

data is an integral part of today’s calibration process.

A CMS must provide the capabilities to easily record such

data.

One of the best ways to collect field data is on a notebook

PC. Calibration technicians can transfer subsets of instrument

records from the main CMS into the notebook-based CMS module.

Calibration activities and events are then recorded in the

field on the notebook, and the data are transferred to the

main CMS. This process eliminates redundant data entry and

paper, greatly reducing the risk of error. A notebook PC

is ideal because it’s an easy-to-use format, powerful

enough to include standard operating procedures as well

as captured measurement data.

As the cost of notebook computers decreases and the advantages

of eliminating pen and paper are realized, a technologically

driven CMS that can provide security features and user options

along with a data-collection utility becomes increasingly

attractive. For paperless calibrations in regulated industries,

robust electronic signatures are also required at the point

of data collection.

Metrics used in calibration management have taken on new

importance as companies strive for global competitiveness.

Along with current software technology, key performance

indicators used in calibration management are proving helpful

in optimizing a range of calibration operations. The concept

of key performance indicators originated with equipment

and facilities maintenance, although the term is a familiar

one to computerized maintenance management system users

as well.

An enterprisewide CMS provides executive-level management

with a window on calibration operations, which in turn supports

decision making and productivity benchmarking. It’s

therefore not surprising that calibration budgets continue

to grow as compliance requirements become more stringent

and profitability goals more imperative. Companies are beginning

to see the benefits in handling KPIs in the same way they

handle their instrument calibrations. Business decisions

regarding equipment calibration and repair can be determined

from reliable data.

Controlling KPIs also can improve business performance

by optimizing maintenance intervals, reducing repair costs,

enhancing reliability and increasing productivity. A recent

survey from www.eCalibration.com

determined the top performance indicators in calibration

management. They are:

Productivity measurement

Productivity measurement

Project and capital justification

Project and capital justification

Financial performance analysis

Financial performance analysis

Customer satisfaction

Customer satisfaction

Quality and regulatory issues

Quality and regulatory issues

Enterprisewide systems make the best use of new CMS technology.

For example, an enterprisewide CMS enables an organization

to host the application at a central location while allowing

worldwide access to separate departments and facilities.

In a typical installation, the database application is hosted

on centralized IT servers, configured and controlled by

a corporate quality or metrology group, and used by working

groups throughout the global enterprise. The software enables

each working group to maintain its own dataset configured

to its specific needs--including its own field labels, languages

or time zones--while centralizing the overall implementation

configuration.

An enterprisewide CMS can reduce calibration procedure

writing and management, standardize calibration measurement

data collection and retention, and allow for instant communication

of management and productivity metrics. This system also

functions as a platform for collaborative problem solving,

which is especially important in cases where employee input

is dispersed throughout the enterprise.

Companies that must follow standards or regulations will

quickly realize the advantages of an enterprisewide CMS.

All FDA-compliant companies must validate the software they

use when making products for public consumption. Validation

is an expensive and time-consuming task, but with an enterprisewide

implementation, it would be required only at the central

host site. If a CMS had been installed at each individual

site, then a validation would be necessary for each implementation.

An enterprisewide CMS can reduce validation costs by up

to 90 percent.

It can also add to the bottom line. Through cost reductions

in application licensing costs, corporate IT resources,

internal auditing and training, the enterprisewide CMS provides

the lowest total cost for corporate calibration compliance.

Although the enterprisewide approach standardizes calibration

processes throughout an organization, it’s also possible

to implement a CMS using a site-by-site method.

Not all companies can initially deploy a centrally hosted,

enterprisewide application. Divisions might want to remain

separate from others, an organization might be too diverse

or the infrastructure might not be capable of supporting

such a system. However, companies could require a single

CMS solution for all departments. In such cases, standardization

is the answer.

Individual departments within an organization can purchase

the same CMS, with each site hosting its own copy. This

can be beneficial in several ways. Each facility in a corporation

can purchase on its own schedule and within its own budget

constraints. Also, policies, procedures and processes can

be completely customized for each department. Finally, each

site can benefit from the knowledge and experience of other

sites within the corporation.

For companies whose ultimate goal is an enterprisewide

solution, the site-by-site approach with one CMS is a good

start. Given a well-researched standard technology, all

sites can easily be merged later into one comprehensive

package.

Historically, CMS vendors offered troubleshooting services,

infamously known as “technical support.” Today,

many CMS vendors offer turnkey service that includes project

assessment, system architecture design, systems implementation,

validation assistance, data import, report writing, commissioning

and training. Companies reduce costs and minimize implementation

risks by hiring vendor personnel to install and start up

systems quickly and efficiently.

Quality standards, regulatory requirements and business

goals drive the needs of today’s calibration management

systems. Modern CMS packages offer flexibility, customization

and a robust feature set to exceed those needs.

John R. Grum is the marketing manager at Blue Mountain

Quality Resources Inc. Blue Mountain is the validated leader

in calibration management software. With 15 years of experience

in FDA-regulated and ISO-compliant markets, Blue Mountain

offers a complete solution from site assessment and installation

to training and validation. For more information, go to

www.coolblue.com.

|