|

The

picture of the perfect factory is one that utilizes real-time

manufacturing intelligence to achieve optimized performance

and minimal unscheduled downtime. As market leaders, these

model plants are highly efficient, productive and profitable.

By implementing new technology strategies that yield real-time

manufacturing intelligence, manufacturers can achieve high

levels of optimization and overall equipment effectiveness.

A direct connection to machine controls is used to continuously

monitor, track, compare and analyze production parameters.

This enables manufacturers to uncover opportunities for

improvement and ensure that machines are operating within

defined specifications. Being able to view and analyze monitored

production parameters from anywhere, at any time, is what

provides real-time manufacturing intelligence.

Continuous control-system monitoring can save manufacturers

millions of dollars. The ability to monitor dozens of process

line parameters, such as temperature and line speed, and

alert plant staff to changing conditions can significantly

decrease downtime. Continuous monitoring gives remote engineers

a direct line of sight into process line activity, enabling

them to solve production problems quickly and perform predictive

and preventive maintenance. Real-time manufacturing intelligence

also enables manufacturers to focus on making process improvements

during scheduled downtime.

Although many organizations understand the theory of OEE

as a tool to maximize capacity, few have actually put it

into practice. Continuous control-system monitoring provides

an Internet-enabled OEE tool to monitor the efficiency and

manufacturing consistency of each piece of equipment. A

continuous control system monitoring service that facilitates

constant running of equipment at steady speeds ensures quality

and consistency of products.

Continuous control-system monitoring and data analysis improve

OEE over time through:

• Proactive 24/7/365 technical support and immediate

notification of process deviations

• Reductions in unplanned downtime

• Preventive maintenance

• Continuous process improvement and optimization

of machine speeds and material yield Most important, by

making accurate OEE numbers readily available, manufacturers

can better control machine performance.

Real-time manufacturing intelligence is aimed at turning

raw machine data into valuable information. This information

serves to optimize production and, ultimately, create a

more strategic business.

Data from the factory floor are vital to making informed

business decisions. With a remote monitoring and diagnostics

system, off-site support specialists can proactively support

plant operations and quickly identify potential problems

in the production process. Remote-engineering specialists

deliver this information to the manufacturer in the form

of detailed reports to facilitate ongoing process improvements.

This empowers the manufacturer or specialists with the knowledge

and means to gain a competitive advantage.

Once a problem is detected, it can often be corrected remotely

before a machine or process fails. This proactive approach

can significantly increase plant uptime, help focus internal

resources on business growth initiatives and provide a cost-savings

advantage over traditional reactive support programs that

address problems after they occur.

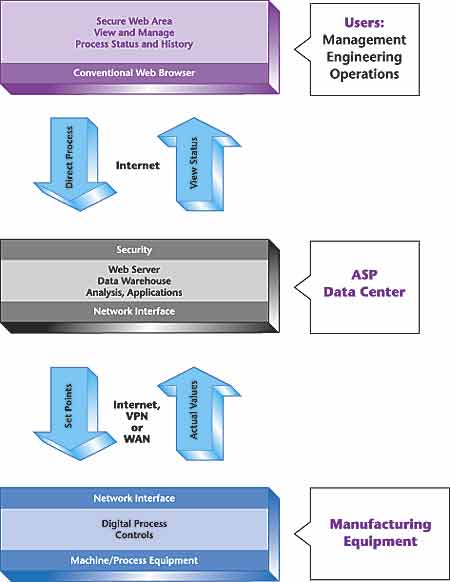

An "always on" connection over a high-speed data

communications network allows plant personnel, business

managers and off-site technical support specialists to monitor

production data around the clock to gain real-time manufacturing

intelligence.

The monitoring system and networks are also designed to

meet all of the corporate security requirements to prevent

intruders from disrupting operations on the factory floor.

Just as the information age fueled worldwide business growth,

real-time manufacturing intelligence is poised to transform

the way manufacturers do business.

Web-enabling process line functions using continuous monitoring

and data analysis services are highly effective in increasing

productivity and OEE. These services enable plant personnel,

business managers and off-site technical support specialists

to view and manage data directly from any Web-enabled PC.

This provides them with a comprehensive view of process

line activity that is unprecedented in scope, detail and

accessibility.

Outsourced manufacturing services utilize the expertise

and technology of a service provider to deliver a cost-effective

productivity solution to manufacturers. Given the right

combination of industry expertise, talent and technology,

a manufacturing service provider can significantly enhance

operational performance—often at a fraction of the

cost it would take to accomplish the same goals using in-house

technology and resources.

By establishing a direct connection to the manufacturer’s

machine controls, the service provider can deliver real-time

technical support and data analysis services to predict,

prevent and accelerate the resolution of equipment problems

from a remote location. In this way, the service provider

becomes an extension of the manufacturing organization.

Utilizing the expertise and resources of off-site engineering

specialists eliminates a significant capital investment

in the hardware, software and administrative staff needed

to support an internal solution.

Outsourced services ensure the highest levels of security,

high-speed networking and fault-tolerant server capacity

to store and process data. Internally hosted software applications,

which provide fragmented and incomplete functionality—in

comparison to outsourced services, are only as reliable

as the manufacturer’s networking and computer systems.

As such, internal software applications are likely to go

down when other systems fail. This is the time when the

latest control system settings, current product recipes

and process line status are most vital to manufacturers.

By storing the manufacturer’s machine settings and

control programs at an off-site location, the service provider

can ensure software recovery in the event of a disaster,

system failure or drive replacement. This enables the manufacturer

to resume operations quickly and without any loss of data.

The outsourced service model is especially practical in

a harsh manufacturing environment, where delicate computer

equipment is at greater risk for damage.

Outsourcing control system monitoring and analysis is simply

more cost-effective, faster and easier to deploy than in-house

investments in technology and personnel.

Because downtime is one of the most costly conditions a

manufacturer can experience, a proactive technical support

program can generate significant cost savings. In order

to effectively diagnose problems and make process improvements,

it’s vital that remote engineers have a deep understanding

of the manufacturing industries in which their customers

specialize.

I

By leveraging real-time manufacturing intelligence acquired

through continuous control-system monitoring, remote-engineering

specialists have the insight to solve process line problems

more quickly, efficiently and effectively than traditional

technical support centers. Remote-engineering services are

designed to complement a manufacturer’s in-house capabilities,

or assist them with 24/7 technical support to help reduce

internal labor costs.

Continuous-monitoring services can also generate cost savings

by protecting existing investments. The direct high-speed

connection used for online monitoring provides a conduit

for regular backup of system software and machine settings.

This protects manufacturers against information loss due

to electrical failure, disaster or system lockup. Regular

backup of machine data also provides version control to

ensure that equipment is operating with the latest settings.

• Analysis tools. Process line monitoring and data

analysis are also used to identify optimum production benchmarks

and set thresholds for process variables. When any metric

that affects output quality falls outside "best case"

standards, plant staff are alerted.

Outsourced technical support staff also leverage monitored

parameters by providing insightful reports on how to reduce

costs, improve quality and enhance productivity.

• Historical database. By storing monitored machine

parameters and reporting support cases to a central database,

plant managers and remote engineers can cross-reference

current process line data with past activity to more quickly

identify and solve problems.

• Automating traditional manual processes. Continuous

monitoring and data analysis services can also be used to

incorporate traditional manual processes, such as quality

assurance testing, into an Internet-enabled centralized

data repository. This augments process line problem resolution

and maximizes production uptime.

Every manufacturing company is different. Some are big.

Some are small. Some have process experts on staff. Some

don’t. Some need help in a few specific areas of production.

Others need help in many areas of production. Fortunately,

because outsourced services are cost-effective and flexible,

they provide the best solution for any manufacturer.

Continuous monitoring and data analysis of process line

activity, coupled with remote 24/7 engineering support,

can help manufacturers realize optimized production. These

services bring manufacturing operations in closer alignment

with corporate headquarters, to ensure that business plans

are in step with the needs and goals of the plant, and vice

versa. They also pave the way for the future integration

of enterprise applications that synchronize manufacturing

operations with customers and suppliers. This holds great

potential to accelerate and enhance the entire manufacturing

process from raw material to finished product.

Brett Smith is co-founder ei3 Corp., which specializes in

using the Internet as a vehicle to help manufacturers improve

productivity. Prior to the launch of ei3, Smith served on

the restructuring team for Delta V Technologies, an industrial

engineering subsidiary of Presstek Inc. Letters to the editor

regarding this article can be e-mailed to letters@qualitydigest.com.

Copyright 2002 ISA—The Instrumentation, Systems and

Automation Society. All rights reserved. Used with permission

of ISA. This paper will be presented at the ISA 2002 Emerging

Technology Conference, Oct. 21–24, 2002, in Chicago.

|