| by H. James Harrington and Thomas McNellis

Since their early years, when

they were known only as bastions of statisticians and inspectors,

quality departments have developed into some of the most

influential and integrated operations in international business.

How has this come about? How are the eye-popping expectations

demanded by today's CEOs met by successful quality leaders?

They all have similar approaches to building upon change

to develop both their individual values and their quality

operations' increasingly important roles in pursuing customer

satisfaction. Inherent in this process is the ability to

adapt quickly and advantageously to change.

You might compare organizational change to driftwood washing

onto the shore. With each new wave, expectations arise as

to where this driftwood (change) will land. If it's somewhere

expected, then someone skilled in the quality trade might

pick it up and transform it into something valuable. But

the driftwood might just as readily float back out to sea,

carried away by strong undertows of resistance. The business

world can be just as rough and unpredictable as the sea.

Organizations constantly face the need to change. New

organizational paradigms, supply chain management, customer-relationship

management and continuous strategic improvement initiatives

are just a few examples of corporate changes that have transformed

the way businesses operate.

SixKey Values

|

One area that has grown significantly during

this change is the quality operation. No longer labeled

a department, quality is woven into every aspect of a business

and involves everyone from mail clerks to CEOs. It's not

unusual for one quality initiative to deliver tens of millions

of dollars in savings, which directly affects a company's

bottom line. That kind of success was unheard of in years

past.

What makes quality professionals successful in today's

rapidly changing environment, where expectations flow and

resources ebb? They follow a simple operational excellence

equation that adds up to creating pure quality value. During

the past three years, we've studied a number of successful

quality professionals from international companies and discovered

that the secret of top performers lies in their methods

to harness change and implement innovative ideas. We've

identified six characteristics that add up to quality value.

By developing these characteristics, quality professionals

can realize significant gains in value for themselves, their

teams and their operations.

As the world changes, so does the quality professional's

role. Yesterday's standards for success are no longer relevant,

and current business models are replaced by tomorrow's ideas.

Markets are international, and the Internet has collapsed

the space-time "virtual business" continuum to

the point that operating

models are launched for future competitive states. Although

larger companies are no longer limited by previously defined

business boundaries, they're still catching up to their

smaller, more nimble competitors by optimizing the Internet's

full potential. Partnerships and mergers have complemented

product lines to provide customers with a "one-stop

shopping" experience. Because quality professionals

must monitor and report business-survival metrics while

implementing competitive advantage via improvement projects,

it's imperative that they maintain pace with this whirlpool

of constant change.

Quality professionals convert change into an opportunity

to develop personal value by aligning their skills and capabilities

to the changing organization. No longer spectators, they

must manage their own destinies by building on their strengths

and filling in the gaps that change creates.

Both education and certification are essential for developing

personal value, but neither happens on its own. In fact,

certification has become such an important conduit for business

optimization that some companies are developing their own

quality certification programs. In some cases, certification

is as important as a college degree, and employees are denied

promotion until they complete minimal certification requirements.

Such policies guarantee that a professional has reached

a level of expertise in an area that's critical to conducting

business. Process improvement, project management, certified

quality manager and Six Sigma Black Belt certifications

are strong opportunities for developing and maintaining

personal value.

To maintain certification, the professional must continue

to improve by taking training classes between recertification

dates. Additional training and/or education offers an opportunity

to meet instructors who've researched areas of change. Discussions

and class exercises provide knowledge to those who are filling

the gaps caused by change. Knowledge enables new channels

of perception and discovery and is the only asset that can

be shared with a co-worker without depleting any personal

reserve.

For example, one of the principal components of ISO 9001:2000

is a greater emphasis on management's role in enabling process

efficiency. The quality professional must understand how

the new standard affects the business initiative to avoid

tarnishing the company's reputation. The cost of this education

should be viewed as an investment in a critical asset of

the company: the quality professional.

In the virtual world, change is both inevitable and continuous.

Sales transactions are conducted at the speed of light,

and enterprises must focus on market opportunities over

the Web, cost-cutting through outsourcing and integrating

systems--whether they involve suppliers or customers. This

environment challenges organizations to turn change into

advantage as quickly as possible, which is why quality operations

pay such close attention to company strategy. Quality professionals

know that customers are demanding more personalized service.

In fact, process improvement projects usually begin by defining

how the tactical schedule will align with strategic goals.

However, companies must do more than focus on products

and services to meet their customers' day-to-day needs.

To strengthen the value equation and react quickly to market

changes, they must build very flexible business models.

Because business tactics align with corporate strategy,

misalignment can result from business models that don't

take change into account. With misalignment come negative

effects such as unproductive resources, nonvalue-added tasks

and expensive process steps, which contribute to misguided

team ventures, inordinate time constraints and budget overruns.

Turning Change Into Advantage

|

This phenomenon also tends to reflect unfavorably on the

production cycle, depleting revenue rather than generating

it and exposing competitive vulnerabilities. To provide

greater value, a business strategy should be broken down

into discrete project components that include both short-

and long-term elements. This way, the strategy is nimble

enough to transform change into tactics that reduce defects,

reduce cycle time and increase customer satisfaction. As

companies downsize into seamless models, strategy will be

based more on customer needs and individualized advantage.

Through industry benchmarking, the quality professional

is in an ideal position to notice change. The quality operation

can help the company develop strategic flexibility by identifying

where change should be used to enhance market position.

The quality operation has usurped the quality department

and consists of a dotted-line relationship between change

agents in the field and a quality leader who works with

the executive staff at corporate headquarters. Throughout

the company, sponsors champion process improvement initiatives

in their sphere of influence.

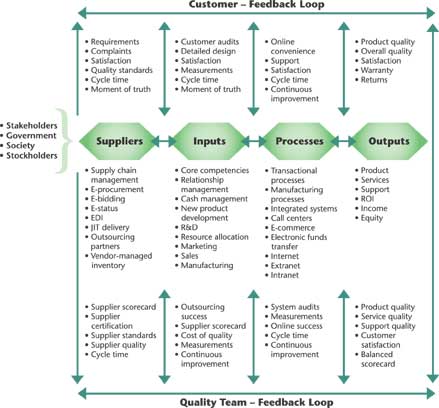

Organizations are also adapting to change by downsizing

their processes and structures. The seamless model is now

the norm for conducting business. The term "seamless"

derives from the concept that silo areas are minimized,

if not eliminated, and every process either touches the

customer or is otherwise outsourced. This lean, suppliers-input-process-output-customers

model is fully integrated and makes the most of data warehouse

knowledge, concept-through-customer cycle time, Web-based

transactional processes, and real-time feedback loops to

monitor customer suggestions and process innovation. Barriers

that prevent improvement are removed in this model. Fresh

ideas that improve products and services are part of everyday

team dynamics.

The quality professional's role in a seamless business

model is to drive organizational value. He or she does this

by monitoring metrics, facilitating continuous improvement

sessions, auditing outsourcing partners and verifying supplier

performance. The quality feedback loop represents the organization's

pulse and nurtures innovative changes by analyzing the pace

of progress. The quality professional verifies that the

company fulfills customer requirements completely and profitably.

Whether it's dealing with government regulations, supplier

performance, input optimization, electronic process reviews,

manufacturing cost assessments, product and service evaluations,

or customer satisfaction, the quality organization operates

as a catalyst for success.

Every quality professional knows that the customer is

the cornerstone of the value equation. Therefore it's critical

to engage the customer in business strategy. The quality

organization must fully understand how the customer defines

both quality and value. Many customers consider these concepts

as separate entities with differing characteristics. For

example, quality can be based on product or service standards

and expectations, whereas value might be representative

of total customer satisfaction.

Together, the two components provide insight into how

well a company meets all of the customer's needs. Obtain

this essential information directly from the end-user, and

then compare it against the viewpoints of distributors,

independent agents and internal executives to analyze misalignment

between strategy and tactics. Value will usually change

from customer to customer, so there must also be a way to

maintain that information. A data warehouse usually fulfills

this requirement.

Once a customer's needs are understood and fulfilled, changes

in customer requirements can be easily absorbed into the

flexible, short-term strategic goals. In this way, the quality

professional creates a value relationship with the customer.

By blending the customer's short- and long-term requirements

into

business strategy and tactics, an organization improves

its chances of gaining the customer's commitment and loyalty.

Customer satisfaction measurements are important in maintaining

the gain. These measurements should be used to further refine

the company's direction of change.

Quality is the essence that provides competitive advantage;

change is the catalyst that promotes an opportunity to strive

for a higher level of team efficiency. Increasingly, companies

focus on streamlining and realigning processes explicitly

so that customer satisfaction drives every aspect of business.

The quality group has also undergone a transformation in

the way it operates. The responsibility for quality no longer

resides in one department but is evenly distributed across

the company. Because quality is everyone's job, quality

teams consist of transorganizational business members who

monitor measurements of success and address issues of variation

before they become serious.

Transorganizational quality teams have launched some of

the greatest and most innovative ideas. This new model for

team-member effectiveness encourages a cross-polarization

of creativity and helps the organization react quickly to

change. A team that comprises multiple contributors has

the advantage of understanding how change might be best

aligned within multiple areas of the business cycle.

To create maximum value for their efforts, members draw

upon the total strengths of their quality team. It's imperative

that teams have the knowledge and skills necessary to succeed

at their jobs. They should also understand their roles in

supporting exemplary performance. Meeting regularly to discuss

best practices and lessons learned enables teams to continuously

improve. When a process improvement leader draws upon so

many different strengths, the team's output is usually greater

than the sum of its parts.

In the past, only the purchasing department dealt directly

with suppliers. If there was a need for a product or service,

the procurement agent sent a stack of design details out

to a multitude of suppliers and established a deadline for

responses. The process was driven entirely by price, and

the relationship was based on power and struggle. Company

production forecasts were inaccurate, so inventory levels

remained high to avoid stock-outs.

That process has since changed into a partnership founded

on electronic data interchange, information-sharing, commitment

and vendor management. Streamlining the supply-chain process

can result in tremendous cost reductions. The new trend

toward supplier management is based on the total cost of

doing business, not simply the price of materials. A predetermined

list of selection criteria is used to determine which suppliers

are best suited for specific product areas and/or business

needs. In order for the effort to be successful, however,

there must be a certain amount of openness with production

data, a passion to deliver product and services when needed

and a commitment to getting quality right the first time.

Certainly, not all suppliers are candidates for a partnership

relationship, and in such cases the quality professional's

role becomes critical to the value assessment's success.

The quality team is involved in all aspects of supplier

analysis: selection, certification, performance ratings,

facility audits and product quality assessments. Value is

based on the supplier's ability to meet customer specifications.

Supplier audits are periodically required in order to maintain

a specific level of performance in meeting those specifications.

In the case of vendor-managed inventory, a long-term contract

based on a blanket purchase agreement is usually generated.

Certification is based on a generally accepted quality standard,

such as ISO 9001.

Once a supplier is certified, requirements should be met

without the need for constant inspection. Some certification

regimens, such as the Capability Maturity Model, are multitiered

so that the supplier can strive for a certain level of accomplishment

while providing a certain level of confidence to the customer.

This way, continuous improvement is built into the systems

as a supplier graduates from one level to the next.

Performance targets for cycle time, price, just-in-time

delivery, internal inventory reduction levels, quality,

and the ability to meet specifications and production requirements

are just a few of the criteria that make up a supplier scorecard.

These scorecards are posted online so that problems are

recognized quickly. Tough decisions can then be made to

either continue with a particular supplier or open the door

to a competitor. Throughout this process, the quality professional

leads the effort to eliminate waste.

Absolutely. Global competition, economic belt-tightening

and optimizing electronic business will force companies

to downsize and continue to cut costs. Customers will demand

the highest standards of quality at the lowest price. Within

successful organizations, quality will become the focal

point for every effort. And this means the quality team

will become an even more valuable asset than it is today.

The Seamless Model

H. James Harrington, CEO of the Harrington Institute,

is considered the leading guru in performance improvement.

He has written 23 books and hundreds of papers on the subject.

Visit his Web site at www.hjharrington.com.

Thomas McNellis is the dean of e-learning for the Harrington

Institute and is associated with research at a number of

universities. He currently teaches at Temple University

and the University of Phoenix. Letters to the editor regarding

this article can be sent to letters@qualitydigest.com.

|