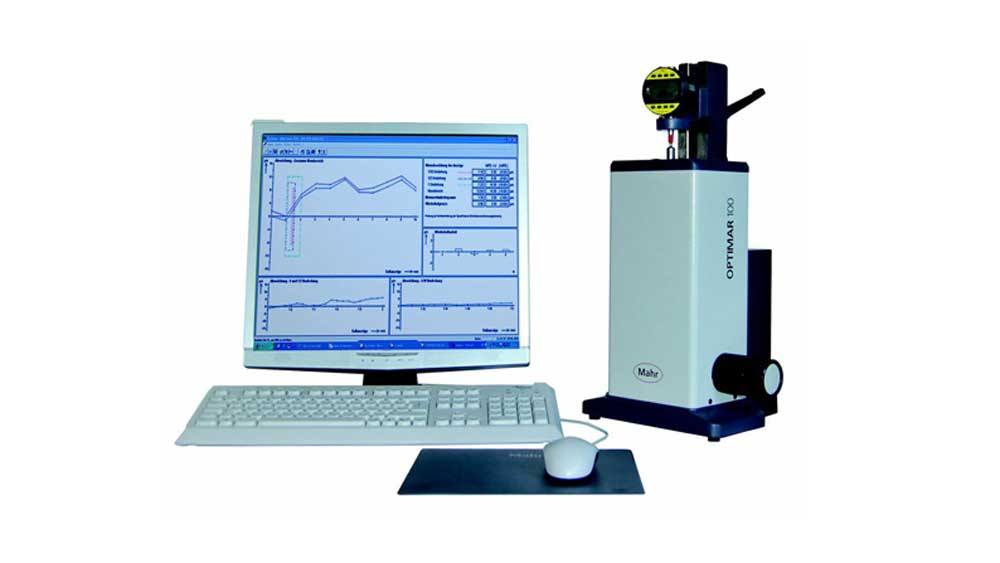

Mahr Optimar 100 dial indicator calibrator

Whether you’re a small machine shop or a large multimillion-dollar manufacturing giant, there’s no doubt you use dimensional gauges to maintain the standards for quality in your production.

|

ADVERTISEMENT |

The accuracy of these dimensional measuring instruments must be periodically checked to ensure that they’re correctly performing the job for which they’re intended. And whether you’re a small shop or a large one, more requirements are being set to document this performance and ensure that all gauging is under control.

In fact, accepted standards call for all manufacturing operations to calibrate regularly or prior to use all inspection, measuring, and test equipment and devices that can affect product quality. They must calibrate their equipment against certified equipment that has a known valid relationship to nationally recognized standards. If there are no predetermined standards, then the basis used for calibration must be documented.

…

Add new comment