Statistics

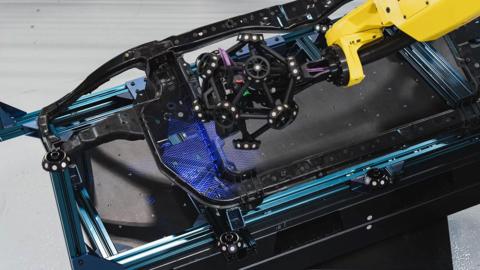

C hallenges abound for today’s manufacturers. Labor shortages and rising labor costs require innovative solutions to maintain productivity with fewer staff. Inflation continues to exert pressure on raw material costs, squeezing margins. Manufacturers are also racing against tight production…

The engineer came into the statistician’s office and asked, “How can I compare a couple of averages? I have 50 values from each machine and want to compare the machines.”

The statistician answered, “That’s easy. We can use a two-sample t-test.”

“How would that work?” asked…

Many countries face the reality of demographic aging: Fertility is plummeting and people are living longer. This raises critical challenges for the labor market, healthcare, and long-term care markets, as well as retirement systems and financial planning. A Wharton symposium on the implications…

In statistics class we learn that we can reduce the uncertainty in our estimates by using more and more data. This effect has been called the “law of large numbers” and is one of the primary ideas behind the various big data techniques that are becoming popular today. Here we’ll look at how the…

Modern fighter jets contain hundreds or even thousands of sensors. Some of those sensors collect data every second, others every nanosecond. For the engineering teams building and testing those jets, all those data points are hugely valuable—if they can make sense of them.

Nominal…

As companies and government agencies push forward with return-to-office (RTO) mandates, they risk exacerbating a workplace problem that many have failed to address adequately: gender discrimination.

New research from the University of Toronto’s Rotman School of Management…