Lean

It’s hard to balance all the demands that are placed upon you as a leader. Many of us default to dysfunctional ways of spending our time and energy. If you know what the common mistakes are and take a more deliberate approach to investing your time and energy, you’ll get better results from your…

In my Labor Day article, “Celebrating Our Frontline Scapegoats,” I observed that of the seven wastes, the one most people recognize is defects. This is understandable: Workers are often blamed for defect-causing situations over which they have little or no control. This article continues that…

A vital concept from the chemical process industry, management of change (MOC) relates primarily to safety. It means that whenever we change a factor in a cause-and-effect diagram (e.g., machine, material, manpower, method, measurement, environment, or any other factor), we create risks of…

Organizations often face a familiar dilemma: It’s not a shortage of good ideas, but a struggle to decide which one to pursue first. During project prioritization meetings, leaders are likely to present a wide range of perspectives. The finance team pushes for hard savings, while operations…

Everybody wants to have good measurements. To this end, many recommend a regular schedule of recalibration. While this sounds reasonable, it can actually degrade the quality of the measurements.

The key to getting the most out of a measurement process is to know when to…

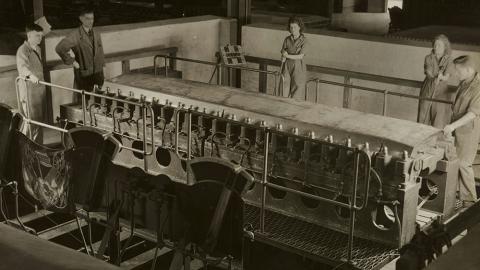

Cutting costs is nothing new in manufacturing. What’s new is having to do it while juggling labor shortages, supplier delays, and tighter customer demands. Lean principles such as reducing waste and optimizing workflows still matter, but they’re no longer enough on their own. Staying competitive…