Curing time is the Achilles heel of multimaterial 3D printing. Typically, a multimaterial 3D printer uses thousands of nozzles to deposit resins, which are then smoothed with a scraper or roller before being cured with ultraviolet (UV) light. As a result, this process is constrained by how quickly the resins cure. This limits the types of materials that can be 3D printed.

|

ADVERTISEMENT |

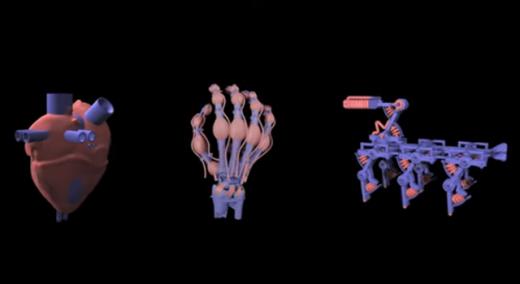

Now, engineers from MIT, ETH Zurich, and the startup Inkbit have developed a new system that uses computer vision to monitor the printing process and adjust deposition rates to ensure material consistency across each layer of a build. Because the system replaces the need for smoothing or scraping, it can work with materials that cure more slowly than the acrylates most commonly used in 3D printing. These include thiol-based materials, which cure more slowly than acrylates but are also more elastic, more stable over a wider range of temperatures, and don’t degrade as quickly when exposed to sunlight.

Moreover, the automatic adjustments make 3D printing on the new system faster than comparable production-grade systems that need to pause or slow down to adjust for curing times. How much faster? Approximately 660 times, according to the researchers.

…

Add new comment