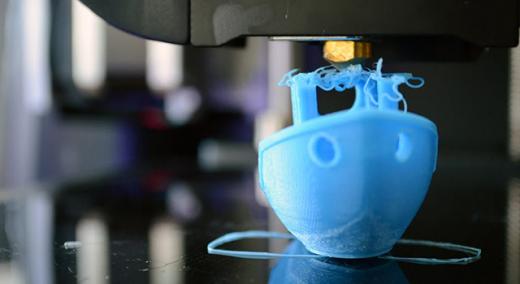

Plastics are a popular 3D printing material, allowing users to create a variety of objects, from simple toys to custom prosthetic parts. But these printed parts are mechanically weak—a flaw caused by the imperfect bonding between the individual printed layers that make up the 3D part.

|

ADVERTISEMENT |

Now, researchers have developed the technology needed to overcome 3D printing’s “weak spot.” The method integrates plasma science and carbon nanotube technology into standard 3D printing.

“Finding a way to remedy the inadequate bonding between printed layers has been an ongoing quest in the 3D printing field,” says Micah Green, associate professor in the chemical engineering department at Texas A&M University. “We have now developed a sophisticated technology that can bolster welding between these layers all while printing the 3D part.”

…

Add new comment