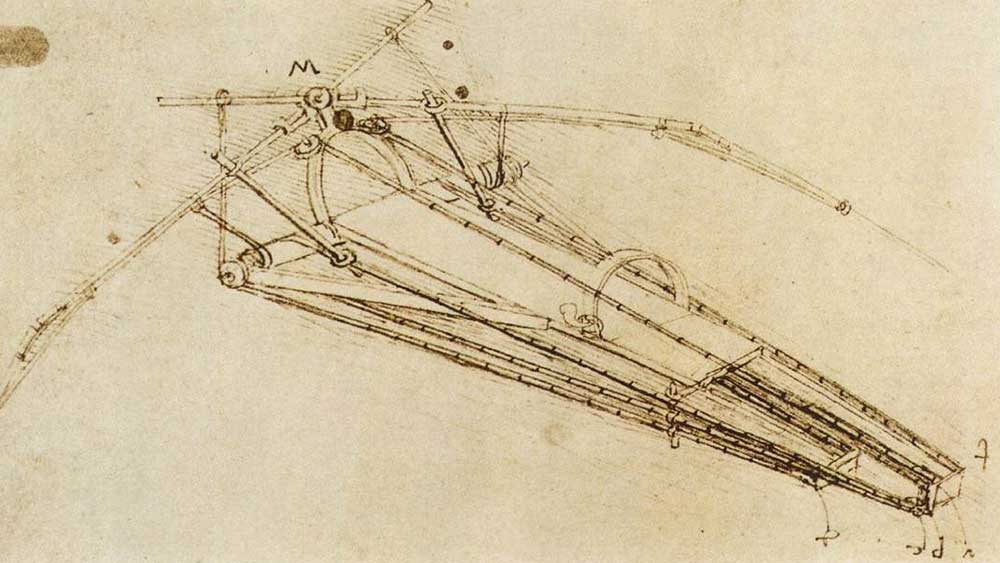

Leonardo da Vinci’s drawing of an ornithopter (aircraft that operates by flapping its wings).

Artificial intelligence (AI) is gaining momentum across a vast array of fields. Nearly everyone has tried or actively uses a form of AI, whether for personal or professional purposes. Many are finding benefits of the technology in industries that use large amounts of data that must be analyzed, consolidated, or organized.

|

ADVERTISEMENT |

Two sectors in particular that meet these criteria but might not be at the top of your mind when imagining the beneficial applications of AI are engineering and manufacturing.

For centuries, engineers relied on manual, handwritten designs as the blueprints for their creations and subsequent manufacturing processes. Countless times, these designs were the only thing used to re-create a tool or machine part.

Today, engineers and manufacturers are looking to AI and digital solutions as a means to preserve these valuable designs and continue to build upon the wealth of knowledge preserved in their libraries of manual drawings. As we explore the applications of AI and knowledge-preservation solutions regarding hand-drawn designs, we’ll realize that solutions to this longstanding problem are available and that the question is more about the speed of adoption.

…

Add new comment