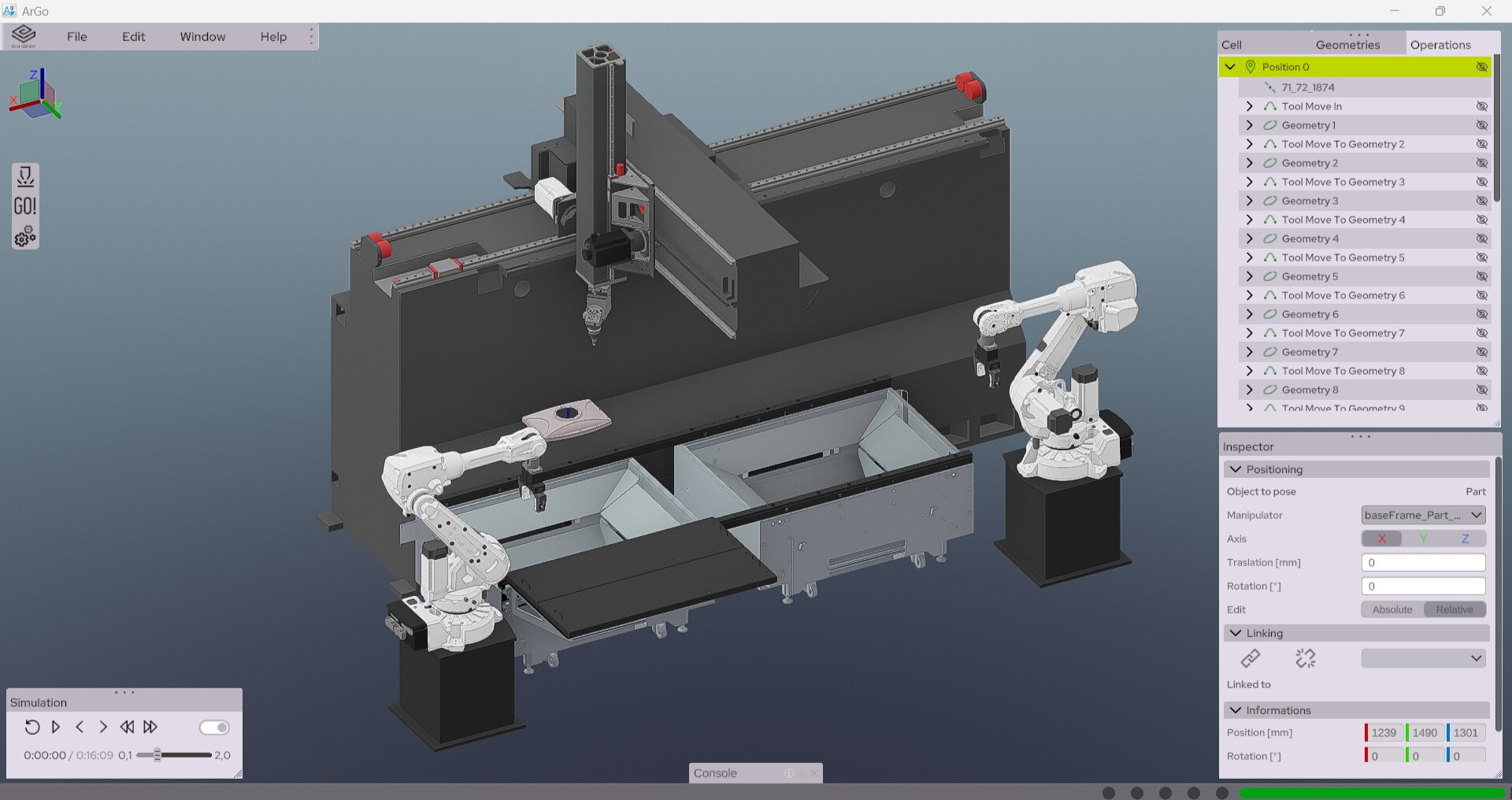

(BLM: Novi, MI) -- BLM GROUP USA has announced the availability of ArGo, a new scalable and customizable CAM programming software dedicated to 5-axis lasers. ArGo enables the complete management of tubes and three-dimensional metal profiles such as deep-drawn, stamped, die-cast, and hydroformed parts. The software features a simple, intuitive interface and seamlessly integrates with other BLMelements software offered by BLM GROUP.

|

ADVERTISEMENT |

Lorenzo Carminato, business development manager of BLM GROUP USA, says, “We are excited to offer this new programming software to our customers, knowing that it will empower them with more capabilities for their 5-axis lasers. ArGo is the result of 20 years of expertise from BLM GROUP trailblazing tube-processing solutions, allowing for the connection between virtual software and real-world machines.”

Comprehensive tube management

ArGo provides automatic recognition of cut and bent parts, including all aspects related to machining, cutting rules, sections, axes, and bends. This solution represents a significant step toward all-in-one functionality by integrating tube benders and tube laser systems, calculating material elongation, and correcting the position of cutting geometries to ensure first-part accuracy. With ArGo, users can decide whether to cut the tube before or after bending, even in curved tube sections.

The new software enables offline programming and rapid synchronization with the machine, boosting operational efficiency. ArGo calculates collision-free trajectories and automatically generates part support templates. For curved tubes, handling becomes more automated due to automatic recognition of sections and the bending axis, facilitating the interactive definition of the gripping position along the curved axis. ArGo also allows for machining on stationary or moving workpieces held in place by the robot.

ArGo features reverse engineering capabilities, enabling users to read existing part programs. This allows rebuilding of a complete project starting from an already machined part or transposing the offsets applied on the machine back to a model—all from the office.

Ease of use

BLM GROUP has simplified ArGo use through an advanced human-machine interface that supports programming for the entire cell, including both the cutting machine and the positioning robot. This flexibility enables users to switch cells to process the same part or multiple parts within a single cell. With ArGo, users can easily create a digital twin of the physical machine configuration in a virtual environment. Each machine will have a configuration file that provides the actual location of various devices within the workspace, providing a precise digital representation of the physical system.

Interested users can manage maintenance and upgrade contracts through BLMportal for continuous and optimized service.

Add new comment