Factory and industrial inspections are the backbones of robust quality assurance programs. Inspection is also an integral part of machine system installation and maintenance, as well as in-situ repairs and retrofits. This is why highly competent individuals who understand the metrology methods of industrial inspection are worth their weight in gold. What can such an individual do when there is a glaring need for his expertise? Do as Damian Josefsberg did in 2003: With a smile and a handshake, he started his own metrology services company.

“I was working for a company that sold a laser alignment product,” explains Josefsberg, founder and president of ACQUIP. “I was listening to the problems that plant engineers had that were more complicated than what they could routinely handle. I wanted to provide a specialized solution for these industrial users that was missing from the marketplace, so I started my own company on a Monday morning. At one in the afternoon, I was on a plane for my first job with ACQUIP.”

Josefsberg’s knowledge and drive were rewarded with success, and his company has continued growing.

Originally known for in-line alignment for rotating equipment, ACQUIP has become a world leader in 3D metrology and dimensioning solutions. ACQUIP now specializes in critical time-sensitive alignment services for many industries, including power generation, oil and gas, petrochemical, and marine. ACQUIP’s innovative portfolio of performance-driven solutions shortens outages and enhances the operational efficiency of rotating equipment of all types.

Much of what this successful company does involves outage solutions and in-situ retrofits. In every scenario, accuracy and speed are of the utmost importance. ACQUIP employs laser tracker technology from FARO to help it achieve both. Customers have come to rely on ACQUIP’s ability to deliver outstanding service without sacrificing time or safety.

Outages

The term outage is often used by power-generation and manufacturing industries when referring to equipment stoppage due to any major repairs or maintenance.

“There are two kinds of outages, which have an eloquent language to describe them,” quips Josefsberg. “There’s the planned outage and the unplanned outage. A planned outage is when repairs or maintenance is performed on a schedule. An unplanned outage is when you have a catastrophic failure. Essentially, you can plan the outage, or the equipment can plan it for you.”

Obviously, unplanned outages are less than ideal.

“The unplanned outage—when the equipment decides to go offline—is the most expensive way to go,” says Josefsberg. “In those instances, you don't get to pick the time, or plan any of the people and resources that you need to support that outage. In most cases, your major loss is going to be your loss of revenue due to not operating. That’s going to hurt a lot more than whatever it costs to fix it.”

“Proper alignment of your equipment and making sure that it's precisely set up in a certain way—those things help your operations run more efficiently, and help you avoid having an unplanned outage.”

When companies attempt to perform alignment with their own personnel, they are often confronted with a lack of skill and experience. “Many of the people who really knew about all this stuff have retired or been laid off,” explains Josefsberg. “Apprenticeship and in-house maintenance training programs don’t really exist anymore. It’s an industrywide problem, it’s not just a matter of not knowing how to technically perform that alignment. It is a lack of knowledge that this is something that you have to do during an outage in order to make sure that your equipment works efficiently.”

Today, ACQUIP doesn’t just provide services. A large part of its business is renting specialized metrology equipment for any application. In some cases, the rental clients need to be trained on the use of the equipment they are renting. FARO equipment and software help the ACQUIP team get their clients up to speed quickly.

“Generally, if a client is going to rent a FARO laser tracker, they use FARO CAM2 software,” says Josefsberg. “It's a fairly popular option for people who are renting equipment. We also offer a service called Jumpstart, where we go out and show you how to use the laser tracker for your specific application. As soon as you’re comfortable with it, we leave, and the tracker continues on as a rental. It’s sort of a hybrid rental/training, and CAM2 is fairly simple to teach somebody in a short amount of time.”

The CAM2 software is equally pragmatic as a tool for the ACQUIP team.

“The other reason we use FARO’s software is that we use trackers and ScanArms, and they both run on the same software. It’s also pretty easy to train new employees. So, we use it because it’s ubiquitous with rental customers, and for the ease of training for newer users.”

Because ACQUIP provides services to such a wide range of customers worldwide, CAM2’s versatile reporting modes are a welcome feature.

“It has a standard form where you can drag and drop features to make a report, which makes it easy,” says Josefsberg. “The CAM2 software is very impressive for making a graphical feature-based report, and you can export the readings into Excel. Some of our clients need to see the data in Excel. With the Excel file, we put the data it in a format that power-generation projects engineers want to see. CAM2 Measure 10 gives us the versatility to provide both options.”

Retrofits

Retrofits are a type of outage that require assets to be out of service while the work is being done. Off-line assets mean lost revenue. Completing the job quickly and without error is essential. In the case of scheduled marine retrofits, it means the vessel is in dry dock.

“They have a window between sail times, and they want to get the work done within that window,” explains Josefsberg. “In dry dock, with all the employees and everything going on, it’s probably costing somewhere between one and three million dollars a day.”

Investing in upgrades, however, decreases fuel consumption and saves owners money in the long run.

To facilitate retrofits quickly and precisely, ACQUIP specialists employ FARO’s Vantage laser tracker for 3D feature capture and large-scale measurement and inspection.

The FARO Vantage laser trackers are extremely accurate, portable coordinate measuring machines (CMMs) that enable users to build products, optimize processes, and deliver solutions by measuring quickly, simply, and precisely. The Vantage features FARO’s patent-pending ActiveSeek capability to quickly sync up the user and the tracker to measure faster than any other laser tracker in the market today.

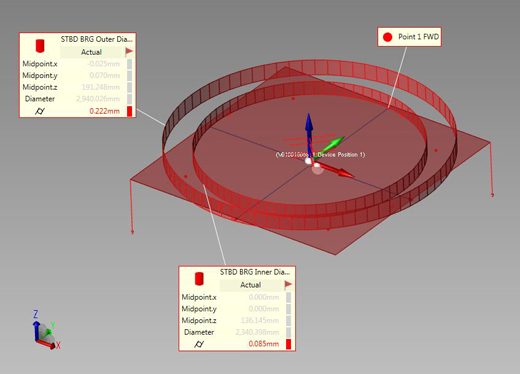

“On a particular job at a shipyard in Spain, the azimuth thrusters were being upgraded, and during the replacement of the drives, the slewing bearings had to be changed out,” says Josefsberg. “We used the Vantage laser tracker to measure the inside and outside diameter of the bearings and map out the casing. We had to ensure that the new bearing was going to fit in the original casing. We were also looking to see if there was any distortion or deformation in the casing or in the bearing.”

The CAM2 software’s simplified analysis and visual reporting allow users to create a coordinate system that is common to multiple elements. Users can quickly scan free-form parts and check their quality in real-time. The software provides immediate feedback with different colors to show deviations from the CAD model during the scanning process. This support easy and prompt identification of inconsistencies.

“We found a problematic area that required machining; the bearing was positioned on a vertical lathe,” explains Josefsberg. “We used the laser tracker to precisely position the lathe’s cutting tool in relation to the bearing. During machining, we would take measurements after each cut to make sure the desired dimension was being achieved. It’s a common practice to use a dial indicator for this kind of work, but we're using the tracker because it’s just more accurate and faster.”

“The client was very happy with the results,” says Josefsberg. “The combination of ACQUIP technical competency and the FARO Vantage with CAM2 reporting provided the client with peace of mind. They had confidence in the results. The client mentioned how fast and accurate the service was. They found the process easy to understand, and that aided the communication with their client.”

Add new comment