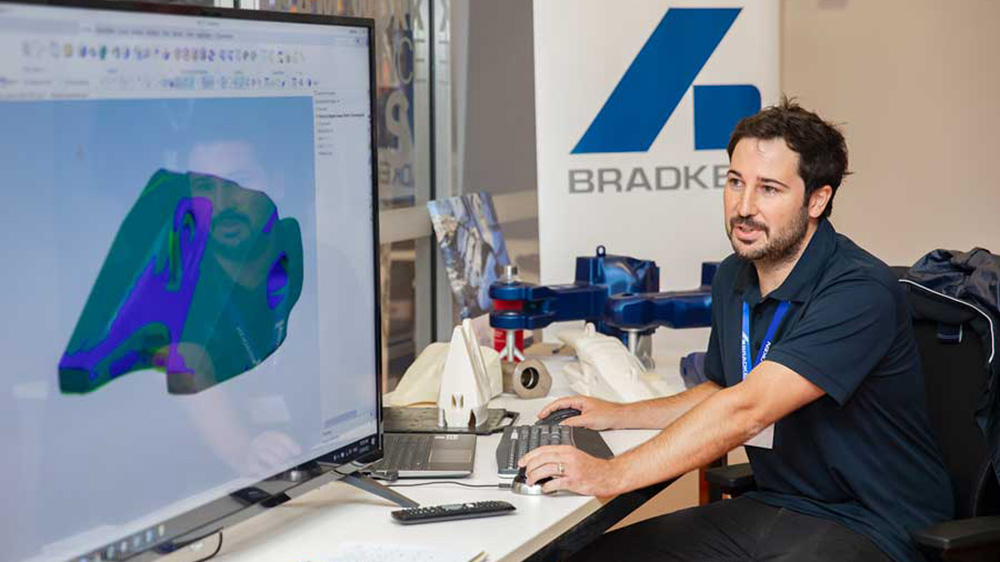

Post-processing a 3D scan in software helps optimize parts. Credit: Creaform.

Maintaining high-quality standards is critical in the heavy equipment industry. Customers rely on manufacturers to deliver products that perform reliably in harsh and demanding operating conditions. The stakes are high. Deviation from quality and overlooked detail can lead to expensive warranty claims and repairs, costly downtimes, and eroded business relationships.

|

ADVERTISEMENT |

Bradken knows far too well the importance of precision engineering and quality control when developing cutting-edge heavy equipment. Founded more than 100 years ago, this Australian-based business has become a leading wear solutions provider to the global mining and resources market. The company’s high-performance equipment helps its customers overcome their bulk handling challenges and ensure their mobile plants operate at peak efficiency.

To maintain its position in the market, staying at the forefront of innovation was nonnegotiable.

…

Add new comment