Processors depend on the filtration of liquids or slurries to meet quality and regulatory standards.

Various industries, including wastewater treatment, power generation, food processing, and chemical manufacturing, depend on industrial strainers to separate unwanted suspended solids from liquids and slurries. However, conventional strainer methods can be unreliable and lead to extensive maintenance, particularly in cases where the debris or solids are of substantial size and there is a significant amount of suspended solids present.

|

ADVERTISEMENT |

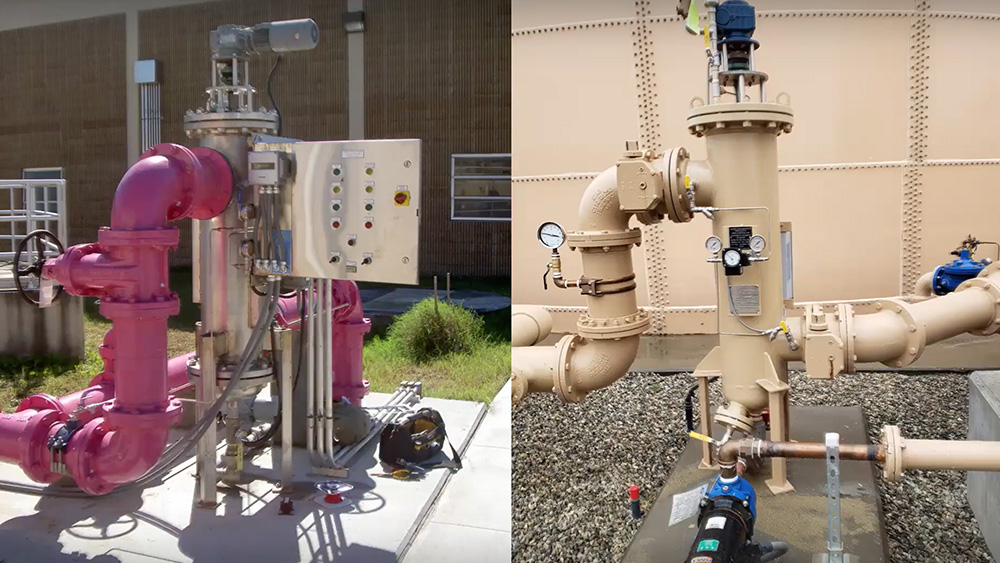

Fortunately, using a novel blend of industrial wastewater technologies allows for the efficient removal of solids without the need for extensive manual labor, worker exposure to messy or potentially hazardous substances, or constant maintenance. The design involves a combination of a macerator, which breaks down large solids into smaller fragments, and an automated scraper/strainer flexible enough to filter out larger debris along with tiny particles. This innovative solution can even accommodate high solids-loading without clogging.

The combination of these two established technologies is already being applied to some of the toughest, dirtiest straining applications, including wastewater debris, power plant boiler-water slag, asphalt transloading, and meat-processing waste streams.

…

Add new comment