Considering the vast number of components in an average manufacturer’s parts library and the number of people who access it, it’s no wonder that problems with parts management arise. For most companies, the solution seems straightforward: create a simple classification system based on the parts’ physical features.

|

ADVERTISEMENT |

However, implementing these systems runs into problems such as subjective categories, inconvenient search processes, and limited integration. Eventually, classification projects reach a point of diminishing return.

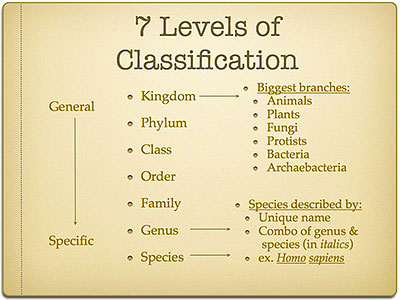

Classification systems are everywhere and have been essential to anyone who has organized anything. The best example is one that most of us have seen in grade school, and that is Linnaean taxonomy. To refresh your memory, this is the diagram that resembles a tree, with the first known (and most basic) organisms on the bottom connected by lines branching out into the many different kingdoms, orders, species, and so on that we know today:

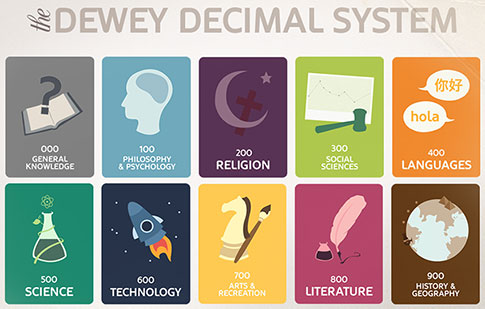

Another familiar classification system is the Dewey Decimal System, which categorizes books within libraries by assigning each with a series of numbers corresponding to the nature of the book. In this system, there are 10 different main classes, such as philosophy, religion, and social sciences, that books can fall under. Then there’s a decimal point, followed by a string of numbers that further categorize the book. By assigning each book a code that narrows down to its specific subject, you would theoretically be able to think of a topic then use the system to find books that pertain to that exact topic.

Linnaean taxonomy and the Dewey Decimal System are structures that are similar to the current standard part classification features in CAD systems. Starting with a relatively small number of main categories, parts are first divided into basic groups and then continually subdivided into smaller, more specific groups.

Although there’s no universal definition for categorizing parts, there are a few standard part classification systems that are prominently used throughout industry. Two of these systems are eCl@ss and UNSPSC. The first, eCl@ss, is a detailed organizational structure, while UNSPSC is more of a neutral taxonomy, accounting for classes of products and services but offering no descriptions. Although there are generally four levels to the eCl@ss classification, it begins with 30 different main classes on the top level, and each successive level has multiple choices. With a basic knowledge of mathematics, it’s easy to see that the number of different possible categories can get out of control pretty quickly.

Even when it should be obvious, the solution never is

Issues arise when there’s a discrepancy in how something should be classified. For example, let’s say that a new book on sports medicine is to be entered into a library and assigned a number. Starting with the broadest categories, a problem arises as to whether the book should fall under technology or arts and recreation. What happens when one person’s natural reaction is to classify it one way, and another thinks of a different way?

The same problem will surely arise with a parts classification project. Although there can be rules about how to classify from the top down, they might not be intuitive to all employees. If everyone doesn’t share the same thought process on what the layers of classification should be, there will be waste when employees can’t find a part in a timely manner. This is the first reason a classification project will fall short.

Having a classification system that isn’t intuitive to all employees can make things confusing to learn, but it also makes finding things even harder. Also, a prominent mindset of “If I can find the parts, why shouldn’t anyone else be able to?” hinders effectiveness. Currently, search options are limited and aren’t effective when browsing for a part to fit a design criterion. If a designer has an idea of what part they want to use, how do they go about finding it? If it is not a standard nut or bolt, it may not immediately be apparent what path to choose. And if that is the only search option, many times designers would rather just model up the part on their own. This leads to problems in duplicating parts that are already in the system, and not keeping a standard across the company.

Finally, most standard part classification systems don’t integrate into other company processes such as purchasing or inventories. This communication is critical to overall product design, and is costly when a problem is discovered late in development. A program that gives designers the added benefit of seeing whether a product is approved before implementing it into the design saves time and increases visibility.

So why doesn’t everyone use the Dewey Decimal System to deduce where to find their book in a library? Because it has been replaced by far faster and easier browsing and searching methods on computers found in almost every library. In the engineering world, CAD technology is relatively young, and it takes time for the problems to become overbearing. Albert Einstein got it right when he said, “If you always do what you always did, you will always get what you always got.”

However, that time is quickly coming, and without an open mind to other possible solutions, the problems of current classification systems will become larger as parts libraries increase. Engineers have longed for a way to find parts quickly but haven’t had the tools to do so until recently. Luckily, there are new solutions to these issues that offer a combination of classification with sophisticated search methods to provide user-friendly and intuitive parts management. More information about classification tools can be found here. A comparison of classification vs. Cadenas’s Intelligent Find can be found here.

Add new comment