Body

For an organization to develop a sustainable, continuous improvement culture, it must, as we say at Greater Boston Manufacturing Partnership, involve everybody, every day—i.e., process improvement must become an everyday part of everyone’s job. That’s the ideal.

|

ADVERTISEMENT |

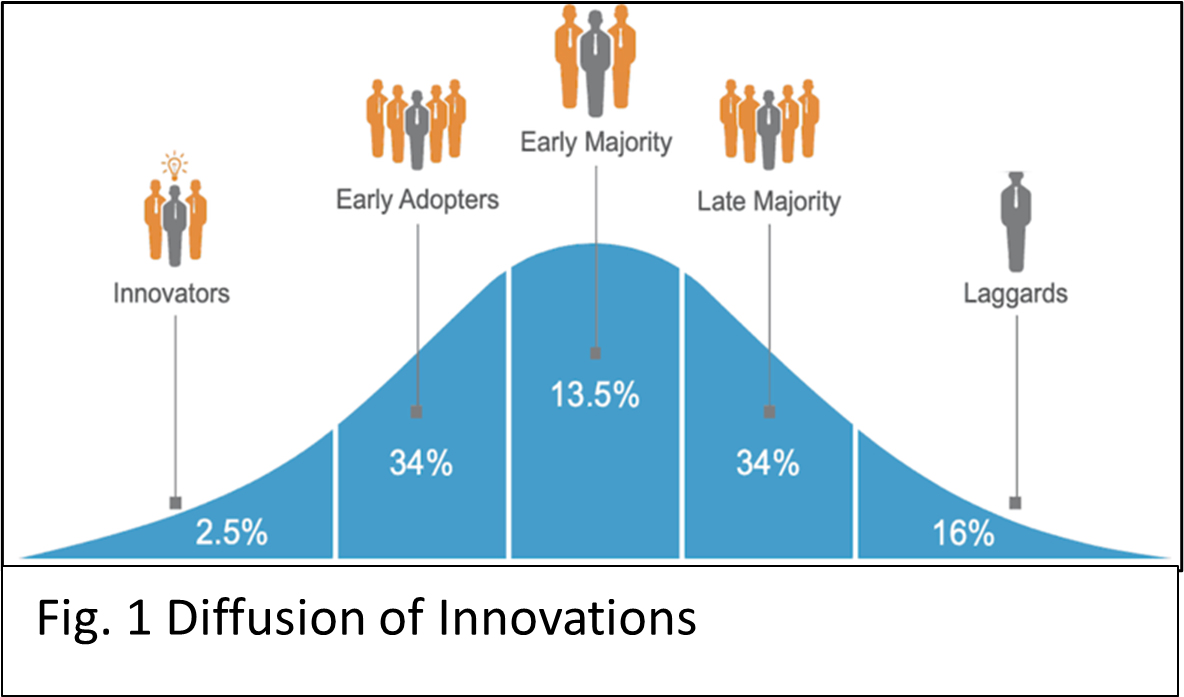

The reality, however, according to Everett Rogers’ Diffusion of Innovations, is that buy-in to this ideal follows a normal distribution, as in Figure 1.

…

Want to continue?

Log in or create a FREE account.

By logging in you agree to receive communication from Quality Digest.

Privacy Policy.

Add new comment