Managing optical exposure settings is one capability that doesn’t make the headlines, but it’s critical for laser scanner usability and accuracy.

Over the past decade, technological improvements have seen 3D laser scanning become an increasingly important alternative to tactile measurement in an expanding range of measurement applications.

|

ADVERTISEMENT |

The success of laser scanning owes as much to under-the-hood technologies that improve the usability and flexibility of scanning as it does to improvements like points/mm, laser line length, and data acquisition rate.

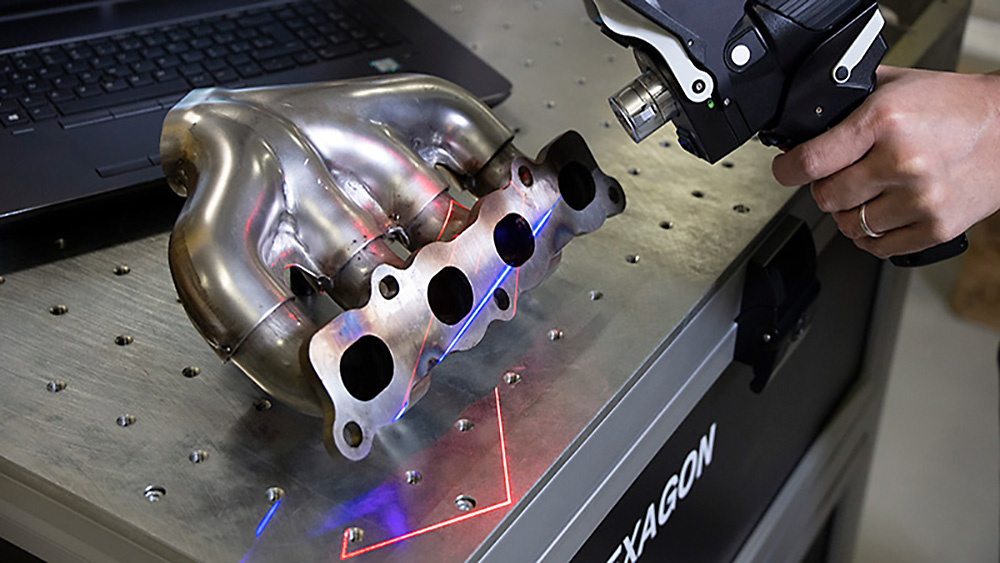

Managing optical exposure settings is one capability that doesn’t make the headlines, but it’s critical for the usability of a laser scanner and the accuracy and efficiency of data capture. This article looks at the development and advantages of a set of optical algorithms created by Hexagon, called SHINE, which has transformed the usability and performance of 3D laser scanning in both portable metrology and traditional coordinate measuring machines (CMMs).

Optical challenges

Modern high-performance 3D laser scanners can now acquire more than a million points in a second, covering an entire object instead of just a few key features, and in much less time.

…

Comments

Scanning made simple!

Great article! Thanks Hexagon!

Add new comment