All Features

William A. Levinson

The famous football coach Vince Lombardi purportedly said, “Winning isn’t everything; it’s the only thing.” (According to Bartlett’s Familiar Quotations, in a 1962 interview Lombardi said, “Winning isn’t everything, but wanting to win is.”)

In light of numerous corporate disasters related to…

Lauren Hinkel

Across the country, hundreds of thousands of drivers deliver packages and parcels to customers and companies each day, with many click-to-door times averaging only a few days. Coordinating a supply chain feat of this magnitude in a predictable and timely way is a longstanding problem of operations…

Roy Arguelles

In today’s marketplace, where products and services proliferate and competition intensifies, businesses are realizing that they must offer more than just commodities to thrive. Enter the experience economy—a paradigm shift where companies are no longer just selling goods or services but crafting…

Bruce Hamilton

I was asked to lead a workshop in the sales order department of a manufacturer that we had helped with process improvement on the factory floor. Those efforts had positively reverberated across the company in the form of fewer late and expedited orders. Still, sales order employees were wondering…

William A. Levinson

What do quality and productivity have to do with World War III, which we all hope will never happen? The answer is everything. A massive loss of American manufacturing capability between 1945 and 2024 has conceded enormous advantages to aggressor nations that might be inclined to break the peace.…

Roman Davydov

In 2024, operating in the automotive market has become increasingly difficult. Global and local supply chain disruptions, product quality issues, and ongoing talent shortages are some of the greatest challenges automotive businesses face globally.

The majority of automotive companies already…

Jennifer King

Route optimization algorithms transform last-mile logistics by improving efficiency, cost-effectiveness, delivery accuracy, sustainability, and customer satisfaction, ultimately reshaping the landscape of modern supply chain management. Route optimization algorithms use advanced computational…

Melissa Burant, Marc Schneider

As a manufacturer, you understand that supply chain disruptions happen all the time. What you don’t know is when or how they will affect your operation and business. But assessing your supply chain risks and implementing good supply chain management practices can be daunting. This is especially…

Jamie Fernandes-ETQ

Generative AI took the world by storm in 2023, from the classroom to the film studio, and the writer’s bench to the White House. Enterprises and creative industries worked to figure out how to leverage it in their operations, while classrooms and government entities struggled to govern its use.

In…

The MEP National Network

Building a supply chain network strategy does not have to be complicated. Ultimately, whether you are looking at your supply chain, back office functions, or fill rates, improving your business is about reducing dependencies and avoiding variation.

5 Steps to Building a Supply Chain Network…

Pierre-Nicolas Disser

With concerns for an economic downturn constantly looming, the global manufacturing industry finds itself navigating through a sensitive time. Once bustling factories, go-to for the world’s largest brands, are experiencing an unexpected lull attributed to multiple factors, including inflation and…

Del Williams

To provide food processors with insight into the industry’s current challenges and opportunities, Cablevey Conveyors, a global specialty conveyor manufacturer, and Automated Handling Solutions, a service-focused subsidiary of Cablevey, have released results from an annual proprietary survey…

Gad Allon

Amazon’s incredible growth over the years has made it a textbook example of what it means for a business to scale, going from a scrappy startup in Jeff Bezos’ garage to a multinational corporation with more than 1.5 million employees.

The retailer recently announced it’s hiring 250,000 full- and…

Julie van der Hoop

We’re all familiar with photos of Ford’s production lines in 1920. But would we recognize them today? As part of a broader trend referred to as “Industry 4.0,” systems in many factories have modernized considerably in recent years. This digitization of the manufacturing sector aims to apply…

John Davis

Over the past decade, one of the biggest advances in enterprise resource planning (ERP) has been the ability to communicate and integrate with machines and external software programs to lower costs and increase efficiency. For example, BOM Compare software can reduce engineering costs and get jobs…

Mike Figliuolo

I’m going to take over the world! It’s really fun to say that. It’s even more fun to take action toward that goal.

Our world has gotten smaller. Way smaller. Globalization is an unstoppable trend. But as they say, the trend is your friend, so why not take advantage of it? I don’t care how big or…

Bruce Hamilton

I’ll admit it: After five decades watching U.S. companies turning to simplistic accounting tricks to remain profitable, I’m discouraged.

I was a kid when I first discovered the Toyota Production System (TPS). My eyes were opened to the immense amount of waste in our production and business…

Etienne Nichols

Supply chain management is crucial to any medtech company’s ability to deliver safe, effective, and high-quality devices to their customers.

But as anyone in the industry can tell you, consistently getting the products and services you need to manufacture your devices is harder than it sounds. In…

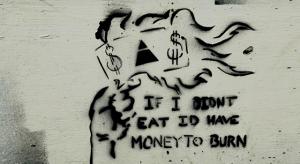

William A. Levinson

Inflation is a serious national issue. Credit agency Fitch Ratings just downgraded the U.S. credit rating—as in the “full faith and credit of the United States”—from AAA to AA+.1 This doubtlessly reflects the fact that our national debt exceeds $31 trillion, or almost $100,000 for every American,…

Rob McAveney

For most discrete manufacturing companies, digital transformation initiatives are underway in some capacity. They’re largely seen as table stakes in today’s economy. Unfortunately, outdated systems and procedures often bring problems that hinder these initiatives.

A lack of consistency among…

Sébastien Breteau

Supply chain quality control is a demanding job. Ensuring that products meet specific standards and expectations for safety and customer satisfaction by monitoring and managing the entire supply chain, from raw materials to finished products, must be accomplished consistently and reliably.

At any…

Jon Finerty

In today’s highly competitive business environment, a trusted supply chain that functions seamlessly is essential. Even small errors can affect the entire supply chain, resulting in lost revenue, unsatisfied customers, and irreparable damage to your brand.

Now more than ever, companies need the…

Emily Newton

It’s increasingly common for today’s warehouse managers to pursue robotic material-handling solutions. That approach can boost productivity, reduce injury rates, and enable companies to adjust to changing demands. However, before company decision-makers choose what kind of robots they want, they…

Robert Mazzucka

Manufacturing has always had an element of matchmaking at its core. As a supplier, you want to be found quickly by original equipment manufacturers (OEMs), prime contractors, and tier one and two suppliers. Buyers want to find companies capable of doing their work.

The ability of manufacturers and…

Joshua Zable

Optimizing inventory, like most problem-solving, requires a thoughtful process and a few steps. Naturally, the easiest way to prevent back orders is to always have a lot of inventory on hand. There are ramifications for not optimizing inventory, though. Overproducing and maintaining high inventory…