To many people, lean manufacturing was invented in Japan and is synonymous with the Toyota Production System (TPS). They will tell you that the TPS is the manufacturing philosophy that enabled Toyota to effectively conquer the global automobile market by reducing waste and improving quality. While that is true, it is not the whole story. Lean has far deeper roots and broader potential.

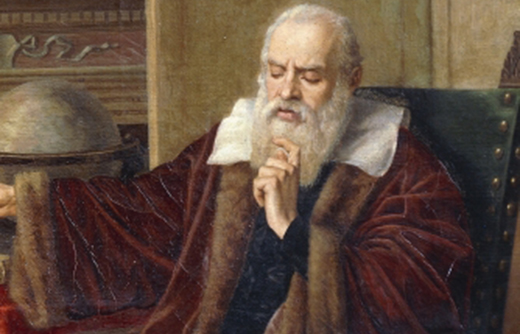

Fundamentally, lean is about creating value and empowering people, not just eliminating waste. It was developed long before Toyota—long before the 20th century, in fact. Some trace the roots of lean all the way back to the Venice Arsenal during the 1500s, when Venetian shipbuilders could roll complete galley ships off the production line every hour, a remarkable achievement enabled by several weeks of assembly time being sequenced into a continuous, standardized flow. (The genius that helped the military engineers at the Venice Arsenal was none other than Galileo himself—perhaps the first-ever lean consultant!)

|

|

…

Comments

A Short History of Lean

Hey Kevin,

Just want to say that this article is well done... nice work!

Shewhart and Deming

Kevin,

As usual, another good read from you. This time I would challenge three points:

1. As per Moen and Norman (Quality Progress, November 2010, p. 27) Deming wrote to Moen in 1990 stating on the subject of the Shewhart cycle “Be sure to call it PDSA, not the corruption PDCA,”, and in 1991 "How the PDCA ever came into existence I know not." – My understanding is that Deming did not alter the PDSA to bring about PDCA. I understood that Deming was not at all a fan of “check”, rather much preferring “study” to emphasise the learning part of the cycle.

2. Your paper suggests Juran and the Pareto chart came before Shewhart’s control chart, yet when Shewhart invented the control chart, in 1924, Juran was just 20. According to Wikipedia (so right or wrong I don’t know) https://en.wikipedia.org/wiki/Joseph_M._Juran#Pareto_principle “In 1941, Juran stumbled across the work of Vilfredo Pareto and began to apply the Pareto principle to quality issues…”

3. I’d also argue that Shewhart invented the control chart as a method to get the most out of a process, moreover to be most useful shouldn't those working on the process be the main users of the method (even though management contribution is essential)?

Add new comment